A kind of low temperature magnesium oxychloride cement and preparation method thereof

A magnesium oxychloride cement and low-temperature technology, which is applied in the field of improvement of magnesium oxychloride cement, can solve problems affecting the structure and volume stability of magnesium cement hydration products, so as to avoid excessive mud temperature, reduce exothermic temperature, and prolong the time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

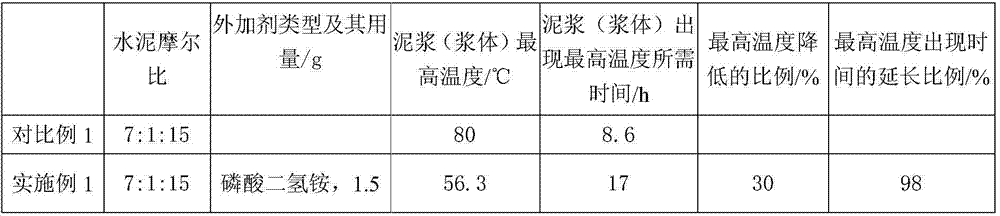

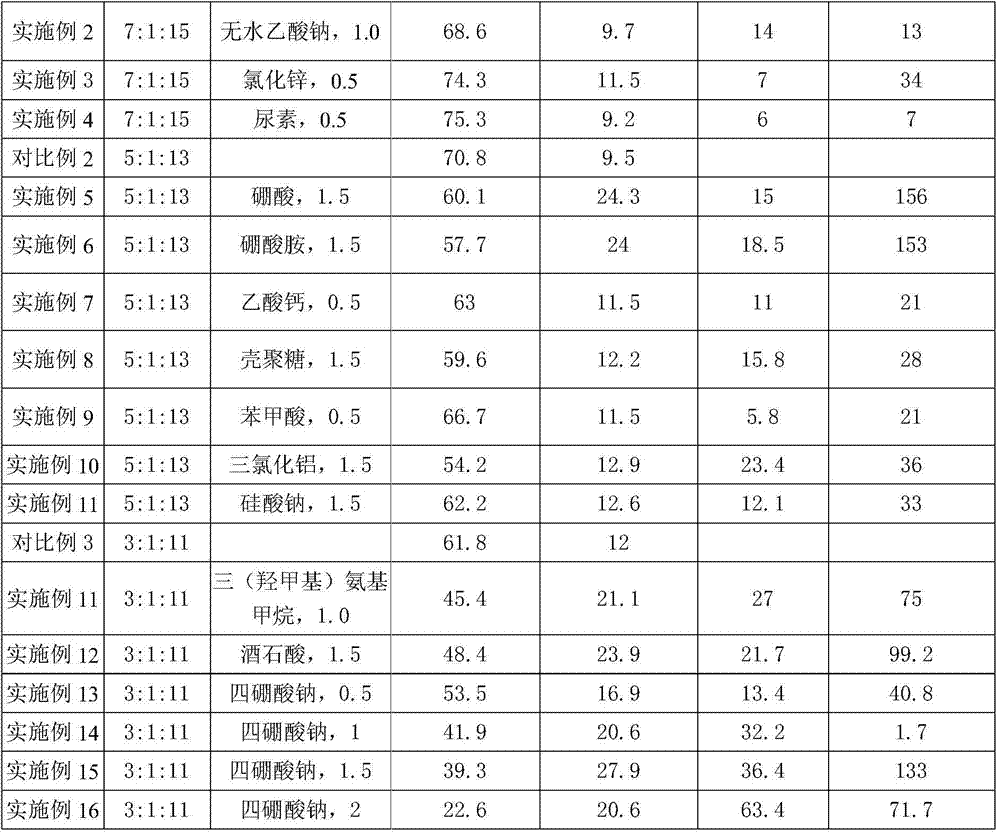

Examples

preparation example Construction

[0011] A kind of preparation method of low-temperature magnesium oxychloride cement provided by the invention comprises the following steps:

[0012] Step 1: Magnesium oxide, magnesium chloride, and water are mixed to form a slurry according to the material ratio of 3-9:1:11-20. Wherein the ratio of the amount of substances of magnesium oxide, magnesium chloride, and water can be referred to as "cement molar ratio" for short. The ratio of the magnesium oxide, magnesium chloride, and water according to the amount of substances can also preferably be 3-7:1:11-15.

[0013] Among them, magnesia is a kind of active magnesia, which can come from various sources, such as lightly burned powder, caustic powder, salt lake by-products, etc. After obtaining various sources, the content of active magnesia will be tested first.

[0014] Step 2: Add additives to the slurry to form slurry. The mass of the admixture is 0.5 to 2 times the mass of the magnesium oxide; wherein, the admixture is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com