A room-temperature fast-curing low-stress transparent epoxy resin adhesive

A technology of transparent epoxy resin and epoxy resin glue, which is applied in the direction of epoxy resin glue, adhesives, adhesive additives, etc., can solve the problems of electrical insulation performance decline, damage, stress deformation, etc., and achieve impact resistance and aging resistance The effect of excellent performance, good maintainability and good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

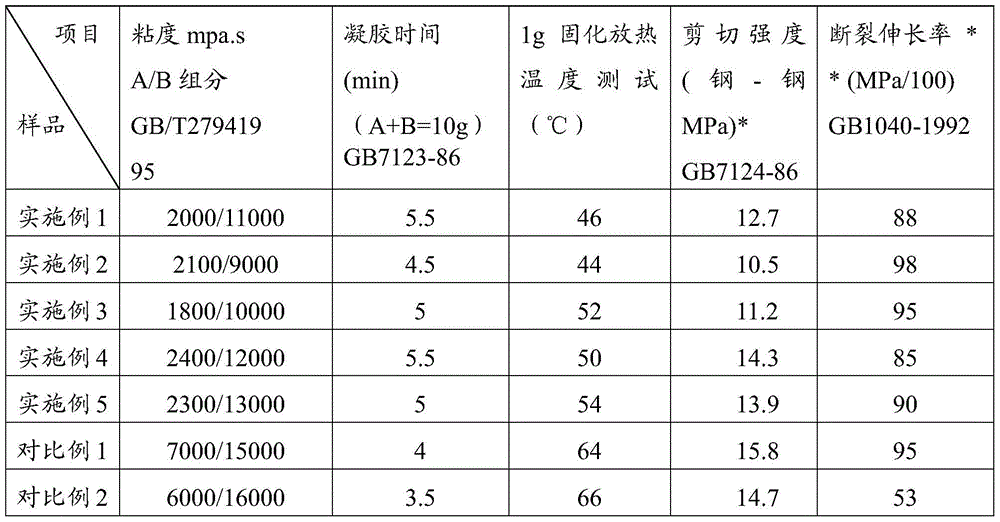

[0034] A room-temperature fast-curing low-stress transparent epoxy resin adhesive, which is composed of a mixture of epoxy resin component A and curing agent B component; (each 1 part is calculated as 10g)

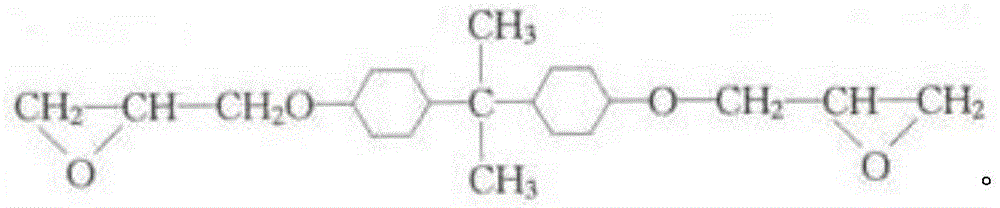

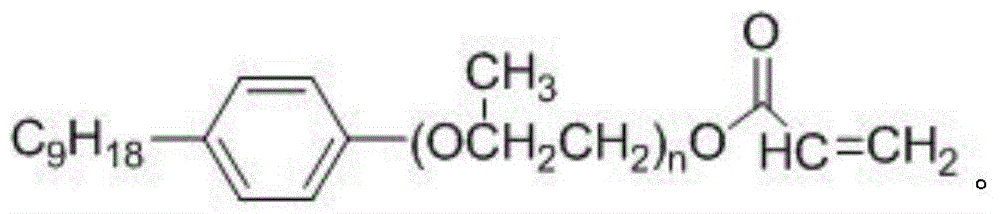

[0035] The epoxy resin A component described therein includes: 680g hydrogenated bisphenol A epoxy resin, 150g bisphenol A glycidyl ether epoxy resin, 100g poly(propylene glycol) 4-nonylphenylene ether acrylate, 30g1,4- Butanediol diacrylate, 30g three (2-hydroxyethyl) isocyanurate triacrylate and 10g KH560; 680g hydrogenated bisphenol A epoxy resin, 150g bisphenol A glycidyl ether epoxy resin, 100g poly (Ethylene glycol) phenyl ether acrylate and 30g of 1,4-butanediol diacrylate were placed in a 2L double star dynamic mixing kettle, stirred at high speed for 30 minutes, and then added 30g of tris (2-hydroxyethyl) isocyanuric acid Stir triacrylate and 10g KH560 for 30 minutes, stir at low speed and vacuumize for 30 minutes, decompress, filter, and discharge;

[0036] The ...

Embodiment 2

[0039] A room-temperature fast-curing low-stress transparent epoxy resin adhesive, which is composed of a mixture of epoxy resin component A and curing agent B component; (each 1 part is calculated as 10g)

[0040] The epoxy resin A component described therein comprises: 550g hydrogenated bisphenol A epoxy resin, 200g bisphenol A glycidyl ether epoxy resin, 150g poly(ethylene glycol) 4-nonylphenylene ether acrylate, 50g 1 , 6-hexanediol diacrylate, 35g tris(2-hydroxyethyl)isocyanurate triacrylate and 15g KH560; 550g hydrogenated bisphenol A epoxy resin, 200g bisphenol A glycidyl ether epoxy resin , 150g of poly(ethylene glycol) phenyl ether acrylate and 50g of 1,6-hexanediol diacrylate were placed in a 2L double-star dynamic mixing kettle, stirred at high speed for 30 minutes, and then added 35g of tris(2-hydroxyethyl) Stir isocyanurate triacrylate and 15g KH560 for 30 minutes, stir at low speed and vacuumize for 30 minutes, decompress, filter, and discharge;

[0041] The curin...

Embodiment 3

[0044] A room-temperature fast-curing low-stress transparent epoxy resin adhesive, which is composed of a mixture of epoxy resin component A and curing agent B component; (each 1 part is calculated as 10g)

[0045] The epoxy resin A component described therein includes: 700g hydrogenated bisphenol A epoxy resin, 100g bisphenol A glycidyl ether epoxy resin, 130g poly(propylene glycol) 4-nonylphenylene ether acrylate, 25g 1,4 -Butanediol diacrylate, 40g tris(2-hydroxyethyl)isocyanurate triacrylate and 5g KH560; mix 700g hydrogenated bisphenol A epoxy resin, 100g bisphenol A glycidyl ether epoxy resin, 130g Poly(ethylene glycol) phenyl ether acrylate and 25g 1,4-butanediol diacrylate were placed in a 2L double star dynamic mixing kettle, stirred at high speed for 30 minutes, and then 40g tris(2-hydroxyethyl)isocyanate was added Stir uric acid triacrylate and 5g KH560 for 30 minutes, stir at low speed and vacuumize for 30 minutes, decompress, filter, and discharge;

[0046] The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com