Preparation method of poly epsilon-caprolactone

A technology of caprolactone and catalyst is applied in the field of preparing polyε-caprolactone, which can solve the problems of difficult removal of metal residues and inability to apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

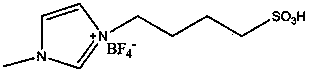

[0017] In a 1-liter glass bottle, add 300 grams of ε-caprolactone, 2 grams of ethylene glycol, and after three replacements with high-purity nitrogen, add 0.05 grams of 1-(4-sulfonic acid)butyl-3- Methylimidazole tetrafluoroborate, heated to 120-140 degrees, reacted for 12 hours, cooled to room temperature, dissolved the product with 2000 ml of chloroform, and precipitated with 5000 ml of ethanol to obtain 280 g of polyε-caprolactone. The weight average was determined by GPC The molecular weight is 30,000, and the molecular weight distribution is 1.3.

Embodiment 2

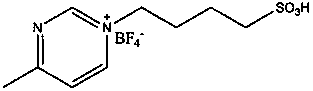

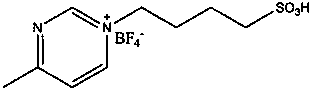

[0019] Add 15 kg of ε-caprolactone to a 20-liter stainless steel reactor with stirring, add 0.15 kg of butanediol, fill with nitrogen and replace the air three times, add 1-(4-sulfonic acid) butyl-3 under nitrogen protection - 75 grams of methylpyrazine tetrafluoroborate, polymerized at 130-150 degrees for 12 hours, then vacuum (vacuum degree 1-10mmHg) at this temperature to remove unreacted monomers to obtain 14.5 kilograms of polyε-hexane Lactone, measured by GPC, has a weight average molecular weight of 10,000 and a molecular weight distribution of 1.2.

Embodiment 3

[0021] Add 15 kg of ε-caprolactone and 0.75 kg of 1,2-propanediol to a 20-liter stainless steel reactor with stirring, fill with nitrogen and replace the air three times, and add 1-(4-sulfonic acid) butyl- 15 grams of 3-methylpyrazine tetrafluoroborate, polymerized at 90-120 degrees for 12 hours, then vacuum (vacuum degree 1-10mmHg) at this temperature to remove unreacted monomers and impurities to obtain 14.8 kilograms of polyε -Caprolactone, the weight average molecular weight measured by GPC is 2500, and the molecular weight distribution is 1.24.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com