Preparation method and application of bismuth titanium tungstate photocatalyst

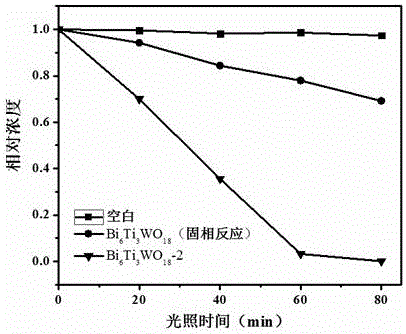

A photocatalyst, titanium tungstic acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, tungsten compounds, etc., can solve the problems of large sample particle size, low photocatalytic activity, high calcination temperature, etc., and achieve reuse rate High, high separation efficiency, simple preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

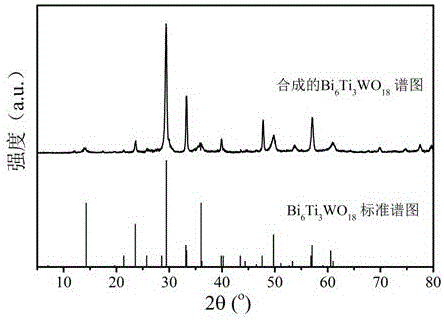

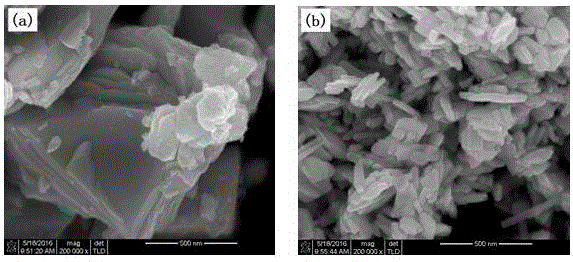

[0022] Dissolve 18 mmol of bismuth nitrate in 60 mL of glacial acetic acid as solution I, and dissolve 9 mmol of tetrabutyl titanate and 3 mmol of tungsten chloride in 20 mL of ethylene glycol monomethyl ether as solution II. Add solution I dropwise to solution II, stir well, heat and stir at 80 °C for 3 h, and finally obtain a brown powder. Weigh 0.2 g of the above brown powder and calcinate it in a muffle furnace at 300 °C for 8 h to obtain Bi 6 Ti 3 WO 18 The nanosheets are the said bismuth titanium tungstate photocatalytic material.

Embodiment 2

[0024] Dissolve 6 mmol of bismuth nitrate in 20 mL of glacial acetic acid as solution I, and dissolve 3 mmol of tetrabutyl titanate and 1 mmol of tungsten chloride in 20 mL of ethylene glycol monomethyl ether as solution II. Add solution I dropwise to solution II, stir well, heat and stir at 130 °C for 3 h, and finally obtain a brown powder. Weigh 0.2 g of the above brown powder and calcinate it in a muffle furnace at 600 °C for 6 h to obtain Bi 6 Ti 3 WO 18 The nanosheets are the said bismuth titanium tungstate photocatalytic material.

Embodiment 3

[0026] Dissolve 18 mmol of bismuth nitrate in 20 mL of glacial acetic acid as solution I, and dissolve 9 mmol of tetrabutyl titanate and 3 mmol of tungsten chloride in 40 mL of ethylene glycol monomethyl ether as solution II. Add solution I dropwise to solution II, stir well, heat and stir at 60 °C for 5 h, and finally obtain a brown powder. Weigh 0.2 g of the above brown powder and calcinate it in a muffle furnace at 400 °C for 1 h to obtain Bi 6 Ti 3 WO 18 The nanosheets are the said bismuth titanium tungstate photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com