Silicomolybdate blue photometric method for determination of silicon in high carbon ferromanganese

A high-carbon ferromanganese and blue light technology, which is used in the measurement of color/spectral properties and analysis by chemical reaction of materials, etc., to shorten the operation process, reduce labor costs, and stabilize the measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

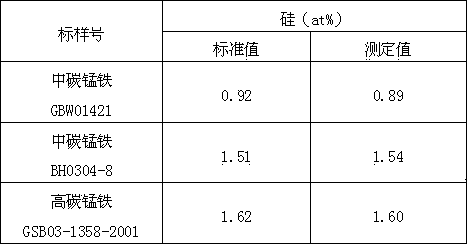

Image

Examples

Embodiment Construction

[0011] 1. Method summary:

[0012] Weigh the high-carbon ferromanganese sample, dissolve the sample with nitric acid, heat and dissolve, oxidize with potassium permanganate until manganese dioxide precipitates, and then add dropwise sodium nitrite solution to reduce it. For samples that still have insoluble matter, it is necessary to carry out residue treatment and redox again. Silicic acid and ammonium molybdate generate silicon-molybdenum heteropolyacid, which is reduced with ferrous ammonium sulfate to generate silicon-molybdenum blue, and the absorbance is measured.

[0013] 2. Reagents:

[0014] 2.1 Nitric acid (the volume ratio of nitric acid with a density of 1.42g / mL to water is 1:3.5);

[0015] 2.2 Potassium permanganate solution (40g / L);

[0016] 2.3 Sodium nitrite solution (100g / L);

[0017] 2.4 Ammonium molybdate solution (17g / L);

[0018] 2.5 oxalic acid solution (50g / L);

[0019] 2.6 Ferrous ammonium sulfate solution: (60g / L);

[0020] 2.7 Mixed solvent (t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com