Internal high-voltage cable for electric automobile

An electric vehicle, internal high voltage technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems that the temperature resistance level of cables cannot be satisfied, the cost and labor increase, and the cable core is easy to be broken. Achieve good shielding performance, resist the interference of external electromagnetic waves, and have the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

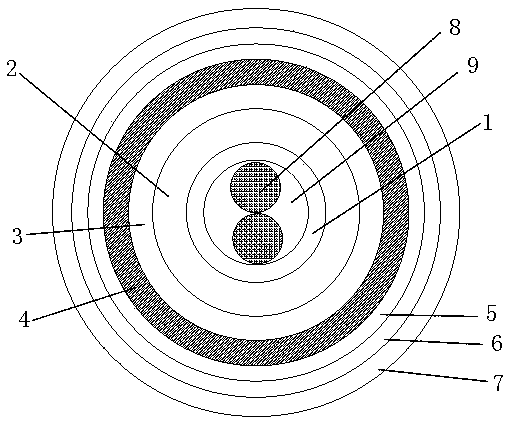

[0018] Such as figure 1 As shown, the present invention mainly includes a conductor 1, an insulating layer 2, a first isolation layer 3, a tinned copper wire shielding layer 4, an aluminum foil shielding layer 5, a second isolation layer 6, and a sheath layer 7 arranged inside the cable; The conductor is arranged at the center of the cable, and the insulation layer 2 is extruded outside the conductor 1, and the sheath layer 7 is extruded on the outermost layer; the first isolation layer 3 and the second isolation layer are extruded sequentially outside the insulation layer 2 6. Weave tinned copper wire shielding layer 4 and aluminum foil shielding layer 5 between the first isolation layer 3 and the second isolation layer 6 respectively; wherein, the insulating layer 2 and the sheath layer 7 are made of heat-resistant 125°C with high C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com