Preparation method of microfluidic three-dimensional gel chip model

A microfluidic and gel technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as high cost, complicated preparation methods, and difficulty in realizing the construction of complex structural network shapes, and achieve Easy preparation and simple adjustment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

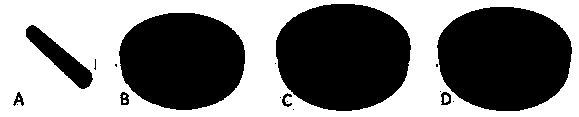

[0023] Agar-embedded calcium alginate columnar "mold" for perfusion of microfluidic 3D biogel single channel.

[0024] Ca used in the preparation of calcium alginate columnar "molds" 2+ The solution is provided by calcium chloride solution.

[0025] (1) Preparation of the microfiber columnar "mold": use a G31 syringe to inject a sodium alginate solution with a mass concentration of 1% into a calcium chloride solution with a concentration of 90 mmol / L at a rate of 100 μL / s at a uniform speed. The glue reacted for 15 minutes to form a columnar "mold" of calcium alginate.

[0026] (2) "Mold" embedded in three-dimensional agar gel: prepare 10ml of agar with a mass concentration of 10mg / mL. Melt and sterilize at 121°C in an autoclave. Immediately after sterilization, take out 5ml of agar and spread it evenly on the petri dish. After cooling, a single calcium alginate "mold" is placed on the gel with injection ports at the beginning and end of the gel. Use 5ml of agar solution ...

Embodiment 2

[0030] Agar-embedded calcium alginate columnar "mold" to prepare perfusion microfluidic three-dimensional biogel dual channels.

[0031] Ca used in the preparation of calcium alginate columnar "molds" 2+ The solution is provided by calcium nitrate solution.

[0032] (1) Preparation of microfiber columnar "mold": Using a G22 syringe, inject a sodium alginate solution with a mass concentration of 1.5% into a calcium nitrate solution with a concentration of 60 mmol / L at a constant speed of 140 μL / s, and the gel After 40 minutes of reaction, a calcium alginate columnar "mold" was formed.

[0033] (2) "Mold" embedded in three-dimensional agar gel: Prepare 10ml of agar with a mass concentration of 15mg / mL. Melt and sterilize at 121°C in an autoclave. Immediately after sterilization, take out 5ml of agar and spread it evenly on the petri dish. After cooling, place two calcium alginate "molds" crosswise on the gel, and reserve injection ports at the beginning and end of the gel. ...

Embodiment 3

[0037] Gelatin-embedded calcium alginate columnar "mold" for perfusion of microfluidic 3D biogel single channel.

[0038] Ca used in the preparation of calcium alginate columnar "molds" 2+ The solution is provided by calcium chloride solution.

[0039] (1) Preparation of microfiber columnar "mold": use a G33 syringe to inject a sodium alginate solution with a mass concentration of 1.2% into a calcium chloride solution with a concentration of 120 mmol / L at a rate of 80 μL / s at a uniform speed, The gel was reacted for 35 minutes to form a columnar “mold” of calcium alginate.

[0040] (2) The "mold" is embedded in a three-dimensional gelatin gel: prepare 10ml of gelatin with a mass concentration of 12mg / mL. Melt and sterilize at 121°C in an autoclave. Immediately after sterilization, take out 5ml of gelatin and spread it evenly on the petri dish. After cooling, a single calcium alginate "mold" is placed on the gel with injection ports at the beginning and end of the gel. Slo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com