Method for functionally modifying composite material laminated board by radar absorbing nano-membrane

A composite material layer and composite material technology, applied in the field of stealth material science, can solve the problems of fiber macroscopic flow velocity mismatch, uncontrollability, dense pores and layered defects, etc., achieve the dual functions of excellent load bearing and stealth, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Nanoparticle selection: a blend of carbonyl iron powder and ferrite, with a particle size of 20nm;

[0032] Polyarylether resin selection: polyaryletherketone;

[0033] The solvent used for configuring the resin solution is selected from: N,N-dimethylacetamide;

[0034] Continuous fiber selection: carbon fiber;

[0035] Resin matrix selection: bismaleimide resin;

[0036] Forming process selection: molding process;

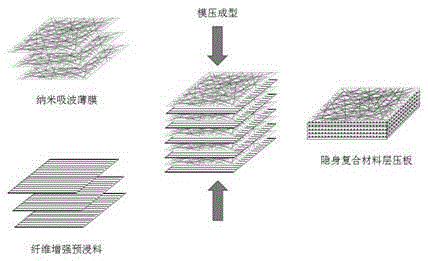

[0037] as attached figure 1 Shown, a kind of nano wave-absorbing thin film functionalization method for composite material laminated board, comprises the steps:

[0038] (1) The blend of nano-carbonyl iron powder and ferrite and polyaryletherketone is prepared into a uniform and stable resin solution

[0039] Specifically: use N,N-dimethylacetamide as a solvent, add a blend of nano-carbonyl iron powder and ferrite with a concentration of 10% by mass, and perform ultrasonic dispersion treatment for 2 hours. The ultrasonic treatment power is 1000W. The ...

Embodiment 2

[0048] In this example

[0049] Nanoparticle selection: carbon nanotubes with a particle size of 5nm;

[0050] Polyarylether resin selection: polyaryletherketone;

[0051] The used solvent of configuration resin solution is selected: dichloromethane;

[0052] Continuous fiber selection: glass fiber;

[0053] Resin matrix selection: epoxy resin system;

[0054] Forming process selection: molding process;

[0055] as attached figure 1 Shown, a kind of nano wave-absorbing thin film functionalization method for composite material laminated board, comprises the steps:

[0056] (1) Prepare carbon nanotubes and polyaryletherketone into a uniform and stable resin solution

[0057] Specifically: use dichloromethane as a solvent, add carbon nanotubes with a mass percentage of 5%, perform ultrasonic dispersion treatment for 0.5h, the ultrasonic treatment power is 300W, and the frequency is 20KHz, and then add polyaryletherketone resin, and the amount of resin is 15% of the amount ...

Embodiment 3

[0066] Nanoparticle selection: carbonyl iron powder, particle size is 60nm;

[0067] Selection of polyarylether resin: polyarylether sulfone;

[0068] The solvent used for configuring the resin solution is selected: N-methylpyrrolidone;

[0069] Continuous fiber selection: carbon fiber;

[0070] Resin matrix selection: bismaleimide resin;

[0071] Forming process selection: autoclave forming process;

[0072] as attached figure 1 Shown, a kind of nano wave-absorbing thin film functionalization method for composite material laminated board, comprises the steps:

[0073] (1) Prepare nano-carbonyl iron powder and polyarylether sulfone into a uniform and stable resin solution

[0074] Specifically: N-methylpyrrolidone is used as a solvent, nano-carbonyl iron powder with a mass percentage of 10% is added, and ultrasonic dispersion treatment is performed for 2 hours. The ultrasonic treatment power is 1000W and the frequency is 40KHz. 30% of the amount of solvent used, mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com