A kind of preparation method of thiamine nitrate massive crystal product

A technology for thiamine nitrate and crystals, which is applied in the field of preparation of thiamine nitrate bulk crystals, can solve problems such as affecting the market competitiveness of products, restricting product processing procedures, uneven particle size distribution, etc., achieving easy control, good fluidity, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

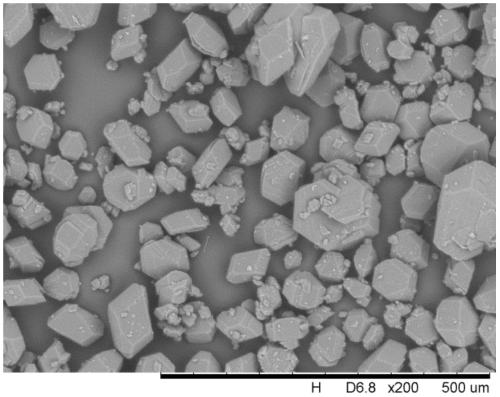

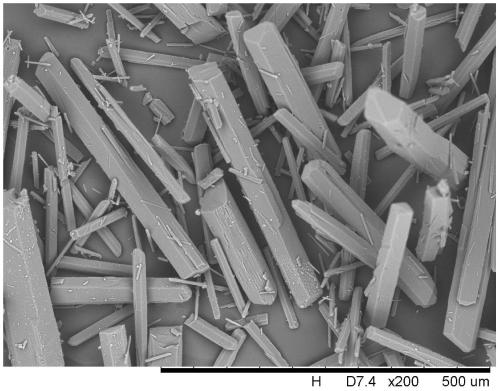

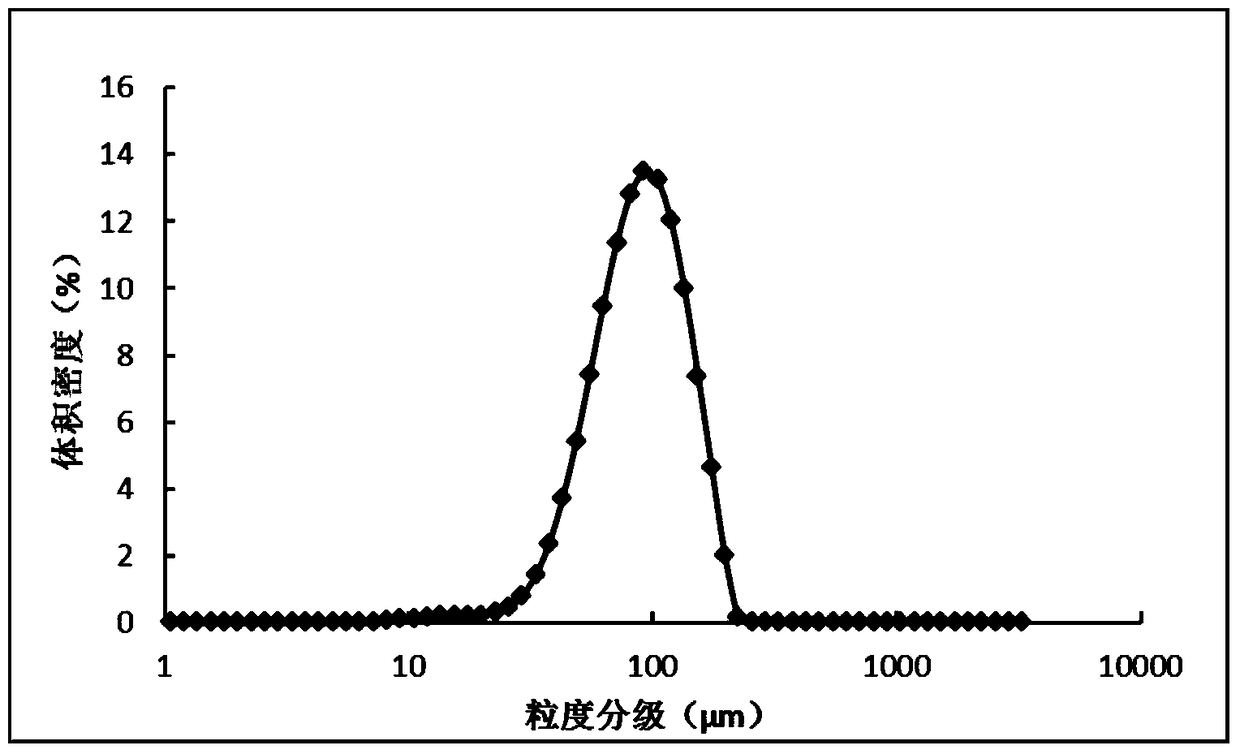

Image

Examples

Embodiment 1

[0035] (1) Use dilute nitric acid solution to adjust 75mL of distilled water to pH = 3.5, add 100g of thiothiamine solids to the distilled water in portions, and stir at a speed of 200r / min. , drop 30% hydrogen peroxide, the total mass of hydrogen peroxide added is 115g, after the reaction is complete, the reaction solution is decolorized with 10g of activated carbon for 1 hour, filtered and set aside.

[0036](2) At 30°C, add 76.5g of ammonium nitrate solution with a mass fraction of 55% to the solution obtained from the above oxidation reaction, and add 0.1g of sodium octadecyl sulfate, stir and mix, and use a mass fraction of 10% ammonia water Adjust the pH. When the pH is adjusted to 3.9, add 1.5 g of thiamine nitrate seed crystals, grow the crystals for 0.5 h, then continue to adjust the pH to pH = 6.8, control the dripping time of ammonia water to 80 min, and then lower the temperature to 5°C.

[0037] (3) Filtrate, wash with 40 mL of absolute ethanol, and dry at 40° C. ...

Embodiment 2

[0040] (1) Use dilute sulfuric acid solution to adjust 75mL of distilled water to pH = 3, add 100g of thiothiamine solids to the distilled water in portions, and stir at a speed of 800r / min. , 20% hydrogen peroxide was added dropwise, and the total mass of the added hydrogen peroxide was 180 g. After the reaction was complete, the reaction solution was decolorized with 10 g of activated carbon for 1 hour, filtered and set aside.

[0041] (2) at 30 DEG C, in the solution that above-mentioned oxidation reaction obtains, add 120g massfraction to be the ammonium nitrate solution of 40%, and add 1.0g decyl sodium sulfate, stir and mix, adjust pH with the ammoniacal liquor of massfraction 25%, When the pH value is 4.0, add 2 g of thiamine nitrate seed crystals, grow the crystals for 1 h, then continue to adjust the pH to pH=7, control the dripping time of ammonia water to 100 min, and then lower the temperature to 5°C.

[0042] (3) Filtrate, wash with 40 mL of absolute ethanol, and ...

Embodiment 3

[0045] (1) Use dilute nitric acid solution to adjust 75mL of distilled water to pH = 4, add 100g of thiothiamine solids to the distilled water in portions, and stir at a speed of 400r / min. , drop 30% hydrogen peroxide, the total mass of hydrogen peroxide added is 115g, after the reaction is complete, the reaction solution is decolorized with 10g of activated carbon for 1 hour, filtered and set aside.

[0046] (2) At 20°C, add 68.5g of ammonium nitrate solution with a mass fraction of 60% to the solution obtained from the above oxidation reaction, and add 0.2g of sodium lauryl sulfate, stir and mix, and use 10% of the mass fraction of ammonia water Adjust the pH. When the pH is adjusted to 3.9, add 1.5 g of thiamine nitrate seed crystals, grow the crystals for 2 hours, then continue to adjust the pH to pH=6.8, control the dripping time of ammonia water to 90 minutes, and then lower the temperature to 5°C.

[0047] (3) Filtrate, wash with 40 mL of absolute ethanol, and dry at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com