Piezoelectric composition and piezoelectric element

A technology of piezoelectric elements and compositions, applied in electrical elements, piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric devices or electrostrictive devices, etc., can solve crystal anisotropy Large, impractical, productivity problems, etc., to achieve the effect of a wide range of practical temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 9

[0087] Bismuth oxide (Bi 2 o 3 ), sodium carbonate (Na 2 CO 3 ), titanium oxide (TiO 2 ), barium carbonate (BaCO 3 ), hafnium oxide (HfO 2 ) and calcium carbonate (CaCO 3 )powder. After the weighed starting materials were mixed by a ball mill for 16 hours, the mixed powder obtained by drying at a temperature of 120°C was subjected to compression molding, and pre-fired at a temperature of 800°C for 2 hours to obtain a pre-calcined powder. Burnt body. Next, the calcined body was pulverized by a ball mill for 16 hours to obtain a pulverized powder.

[0088] A binder is added to the pulverized powder obtained by the above procedure and granulated. Next, the obtained granulated powder was press-molded by applying a load of 3.2 MPa with a press-molding machine, and a flat-shaped compact was obtained. The flat molded body thus obtained was heat-treated at a temperature of 700°C, and further fired at a temperature of 1180°C to obtain a sintered body. In addition, the obtain...

Embodiment 10~15

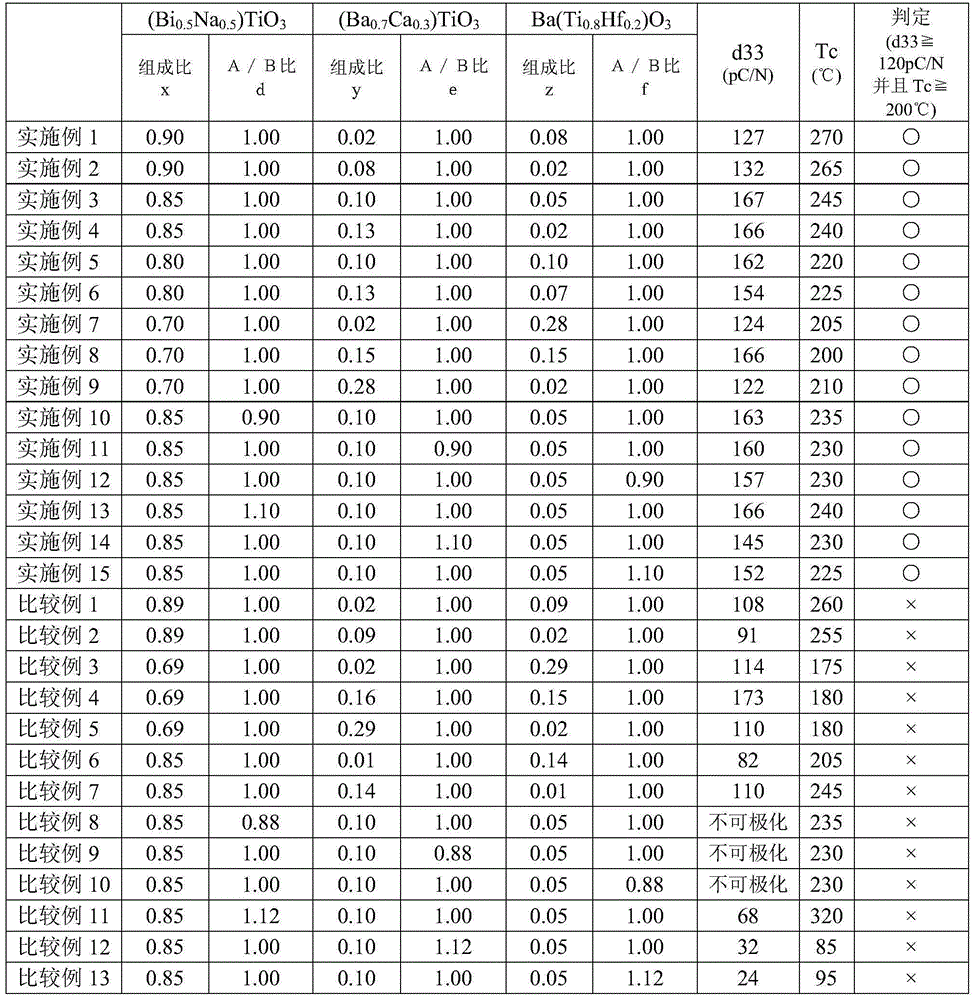

[0100] As Examples 10 to 15, except that x, y, and z are set to x=0.85; y=0.10; z=0.05 for the piezoelectric composition represented by the above-mentioned formula (2) and further to become A piezoelectric composition was produced under the same conditions as in Example 1 above, except that the blending ratio of the starting materials was changed as d, e, and f were shown in Table 1. In addition, for Examples 10 to 15, d was also measured in the same manner. 33 and T c . The measurement results are shown in Table 1.

[0101]As can be understood from Table 1, the ranges of 0.90≤d≤1.10; 0.90≤e≤1.10; and 0.90≤f≤1.10 are good. Therefore, the piezoelectric composition according to the present embodiment is characterized in that the sinterability is improved because it is less affected by the secondary phase due to the difference in the stoichiometric composition ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com