Production method of lithium-containing composite oxide and lithium-containing composite oxide

A technology of composite oxides and manufacturing methods, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problem of cycle characteristics degradation and achieve the effect of improving cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

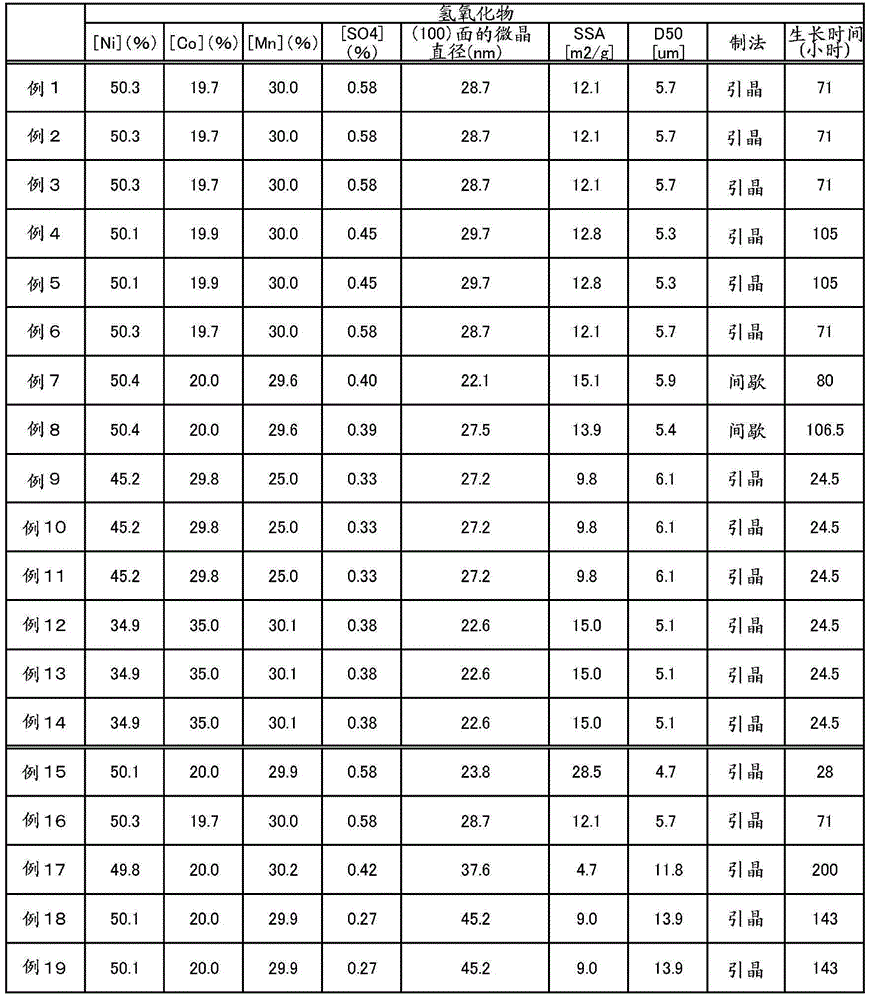

[0112] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to the following Example. In the following examples, Examples 1 to 14 are examples, and Examples 15 to 19 are reference examples. Various evaluations and measurements of each example were performed by the following methods.

[0113] [Measurement of Specific Surface Area (SSA)]

[0114] The specific surface area (SSA) of the hydroxide and the lithium-containing composite oxide was measured by the nitrogen adsorption BET method using a specific surface area measuring device (manufactured by Mountech, device name: HMmodel-1208).

[0115] The measurement of the specific surface area of the hydroxide was degassed at 105° C. for 30 minutes.

[0116] The measurement of the specific surface area of the lithium-containing composite oxide was degassed at 200° C. for 20 minutes.

[0117] [Measurement of median particle diameter D50]

[0118] The median dia...

example 1

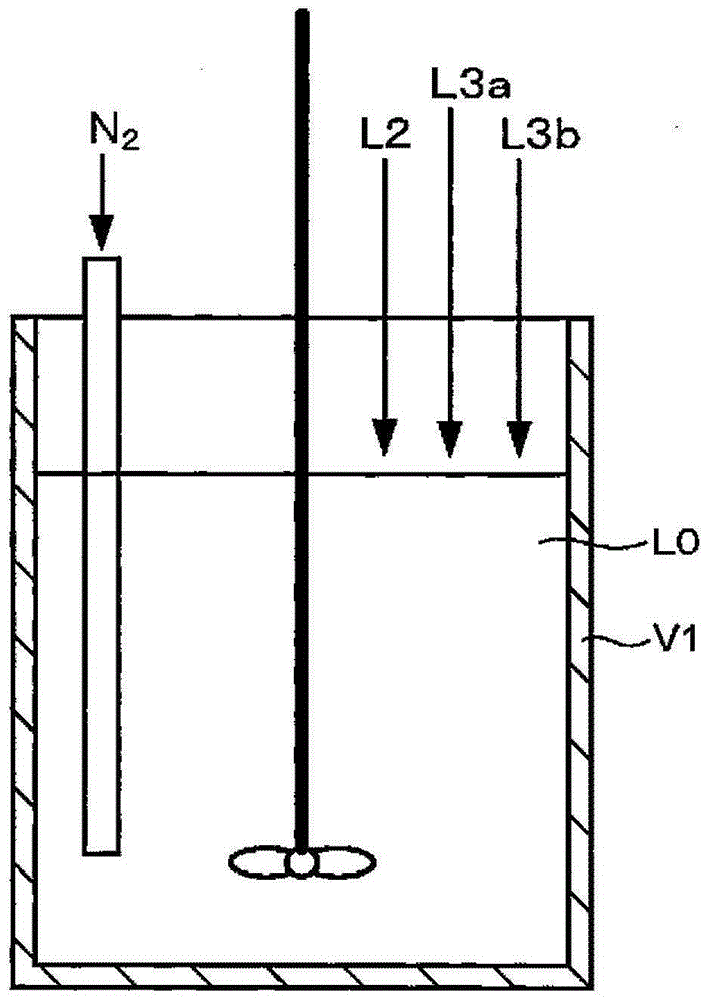

[0136] [Example 1] Production example using the seeding method

[0137] Nickel(II)sulfate*hexahydrate, cobalt(II)sulfate*heptahydrate, and manganese(II)sulfate*hydrate were weighed such that the molar ratio of each element of Ni, Co, and Mn was 0.5:0.2:0.3. Next, these were dissolved in distilled water so that the total concentration thereof would be 1.5 mol / L to prepare an aqueous solution of a transition metal salt.

[0138] Sodium hydroxide was dissolved in water to prepare a 6 mol / L aqueous sodium hydroxide solution. Ammonium sulfate was dissolved in water to prepare a 0.83 mol / L ammonium salt aqueous solution.

[0139] A seed crystal is produced by a co-precipitation method, and the seed crystal is used to obtain a hydroxide by a seeding method.

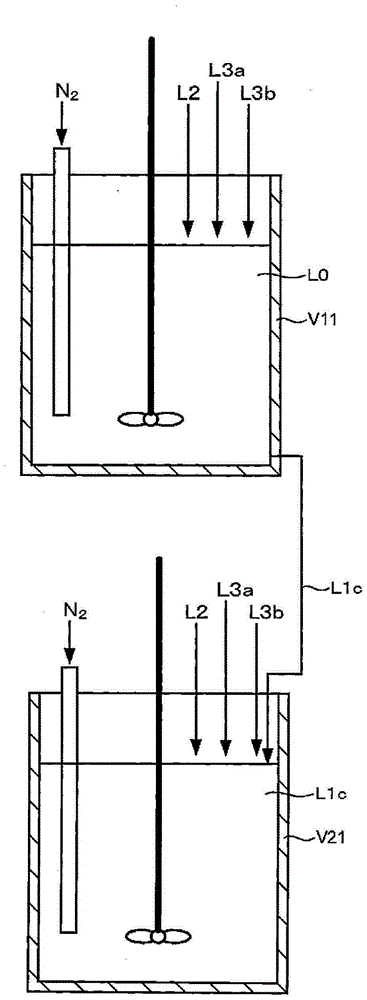

[0140] Distilled water was put into the 1st reaction tank of capacity 30L, and it heated to 50 degreeC. While flowing nitrogen gas in the first reaction tank, the stirring power is 1.3kw / m 3 While stirring the initial soluti...

example 2~6

[0147] A lithium-containing composite oxide powder was obtained in the same manner as in Example 1. However, the growth time of crystals was the time shown in Table 1. Hydroxide, lithium carbonate, and zirconium oxide or tungsten oxide were mixed and calcined under the conditions described in Table 2 to obtain a lithium-containing composite oxide. However, the mixing ratio of zirconia or tungsten oxide in Table 2 being 0 mol% means that they were not mixed. The following are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap