Friction stir welding additive manufacture method of bar material

A technology of friction stir welding and additive manufacturing, applied in the field of manufacturing bars, can solve problems such as cracks and large deformation, and achieve the effects of excellent performance, reduced heat input, and improved overall mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

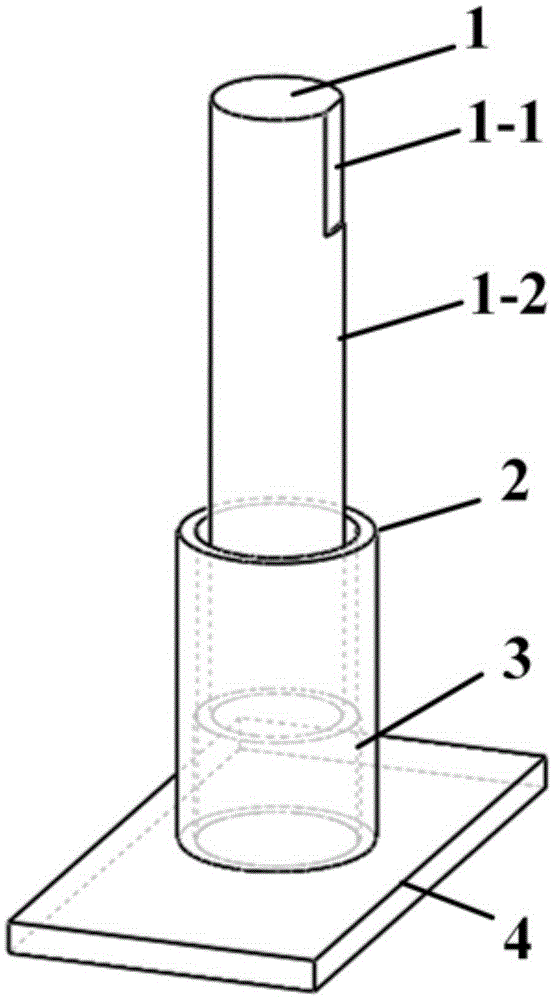

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is a kind of method of friction stir welding additive manufacturing bar, it comprises the following steps:

[0029] Step 1, preparation of cylindrical base metal:

[0030] First determine the type of material for additive manufacturing, and process it into a cylindrical bar 1 with a diameter of 10-50mm and a length of 50-200mm by machining; then process a deep 2- 5mm platform 1-1, the length of platform 1-1 is 10-20mm, so that the bar 1 is mechanically connected with the friction stir welding equipment through bolts; the surface of the bar 1 is polished with sandpaper, and then ultrasonicated in acetone Wash, and finally air dry for later use;

[0031] Step 2. Preparation of additive manufacturing mold:

[0032] Select a pipe with a higher melting point than the additive material to make the mold 2 for additive manufacturing, and remove oil stains and oxide films on the inner...

specific Embodiment approach 2

[0043] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the material for additive manufacturing in Step 1 of this embodiment is a 2024 aluminum alloy rod. It is set in this way to ensure that the rod 1 can be clamped on the friction stir equipment and used as a material source for additive manufacturing. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Specific implementation mode three: combination figure 1 To illustrate this embodiment, in step 2 of this embodiment, a low-carbon steel pipe is selected to make the mold 2 for additive manufacturing, and the oil stains and oxide films on the inner and outer surfaces are removed. The wall thickness of the pipe is 5mm, and the inner diameter is 24mm. Such setting ensures that the mold 2 does not directly contact the high-speed rotating aluminum alloy rod 1 during the additive manufacturing process, and it can restrict the forming space of the additive metal. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com