Novel core-shell structure light and temperature sensing material and preparation method thereof

A technology of core-shell structure and light-temperature sensing, which is applied in the field of light-temperature sensing, can solve the problems that fluoride materials are easily oxidized and cannot realize the detection of light-temperature performance, and achieve improved up-conversion efficiency, good optical properties, crystallization good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of NaY by High Temperature Pyrolysis 0.78 Yb 0.2 Er 0.02 f 4 Fluorescent nano-nuclear material; the raw materials are selected as the following table

[0024] raw material

NaCF 3 COO

Y(CF 3 COO) 3

Yb(CF 3 COO) 3

Er(CF 3 COO)

g

0.136

0.338

0.1024

0.0101

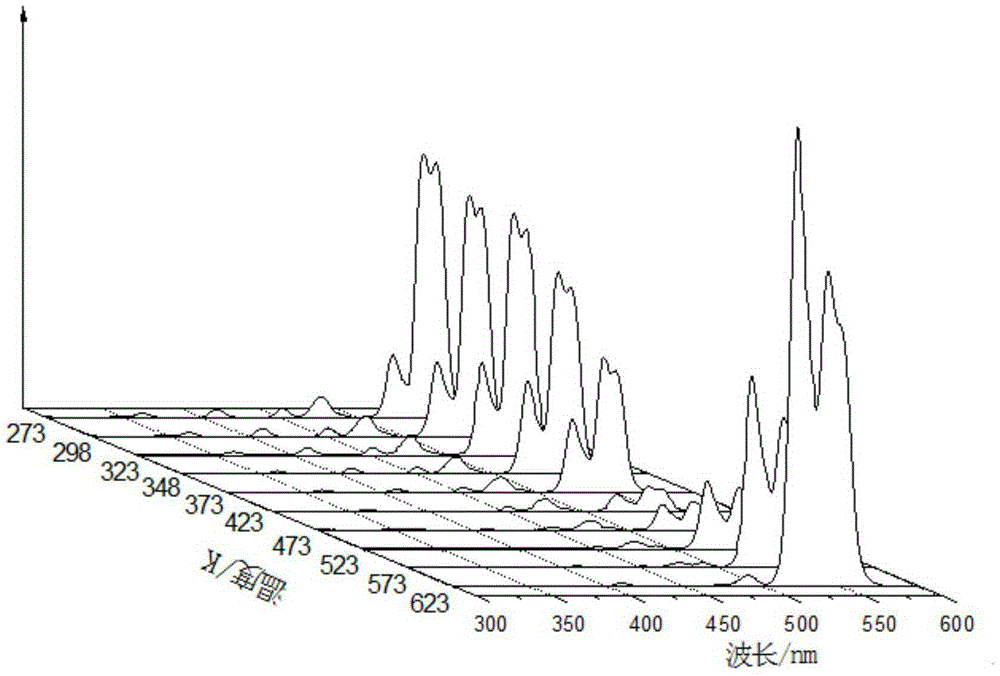

[0025] Weigh the corresponding raw materials and place them in a container; add 16ml of oleic acid and 8ml of oleylamine, pass in argon to raise the temperature to 120°C, and keep it warm for 30min; then raise the temperature to 275°C, and keep it warm for 30min; Add excess ethanol, centrifuge, and dry at 70°C to get NaY 0.78 Yb 0.2 Er 0.02 f 4 Nano-nuclear material, its variable temperature fluorescence spectrum under 980nm excitation is as follows figure 1 shown.

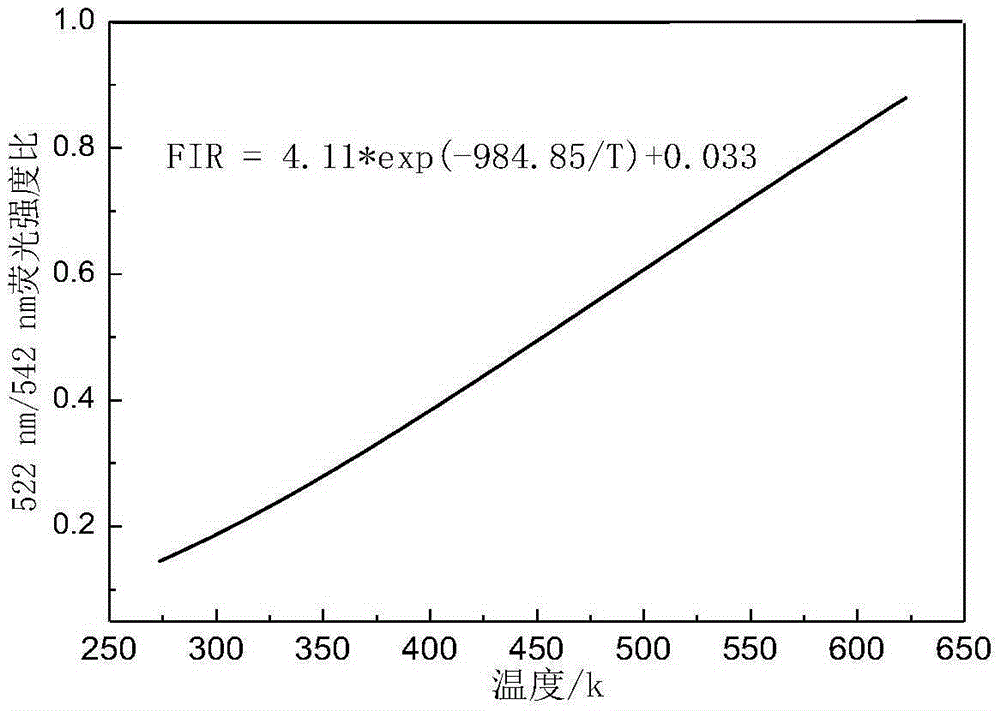

[0026] Using high temperature pyrolysis method in NaY 0.78 Yb 0.2 Er 0.02 f 4 The surface of the fluorescent nano-nuclear material is coated with a layer of NaYF 4 ...

Embodiment 2

[0032] Preparation of NaY by High Temperature Pyrolysis 0.747 Yb 0.25 T m 0.003 f 4 Fluorescent nano-nuclear material; the raw materials are selected as the following table

[0033] raw material

NaCF 3 COO

Y(CF 3 COO) 3

Yb(CF 3 COO) 3

Tm(CF 3 COO)

g

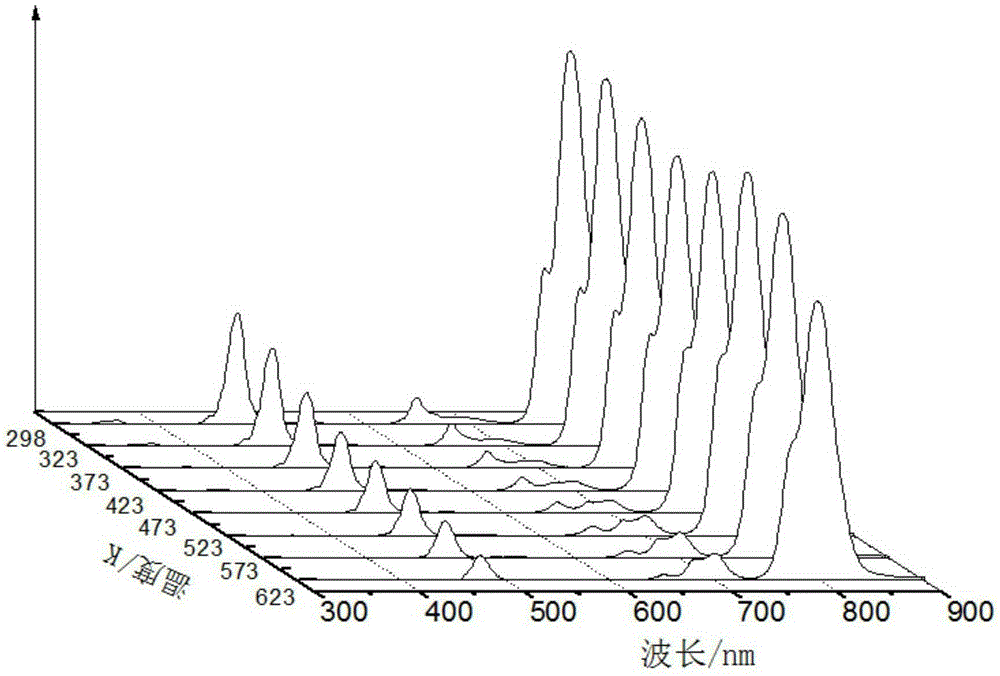

0.1360

0.3197

0.1280

0.0016

[0034] Weigh the corresponding raw materials and place them in a container; add 16ml of oleic acid and 8ml of oleylamine, pass in argon to raise the temperature to 120°C, and keep it warm for 30min; then raise the temperature to 275°C, and keep it warm for 30min; Add excess ethanol, centrifuge, and dry at 70°C to get NaY 0.78 Yb 0.2 Er 0.02 f 4 Nano-nuclear material, its variable temperature fluorescence spectrum under 980nm excitation is as follows image 3 shown.

[0035] Using high temperature pyrolysis method in NaY 0.747 Yb 0.25 T m 0.003 f 4 The surface of the fluorescent nano-nuclear material is coated with a layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com