Recombinant fat as well as preparation method and application thereof

A fat, weight percent technology, applied in the application, edible oil/fat, food ingredients as taste improver, etc., can solve the problem of high unsaturated fatty acid content, difficult application of liquid lard, recombinant fat saturated fatty acid, cholesterol content Low and other problems, to achieve the effect of lowering cholesterol and saturated fatty acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

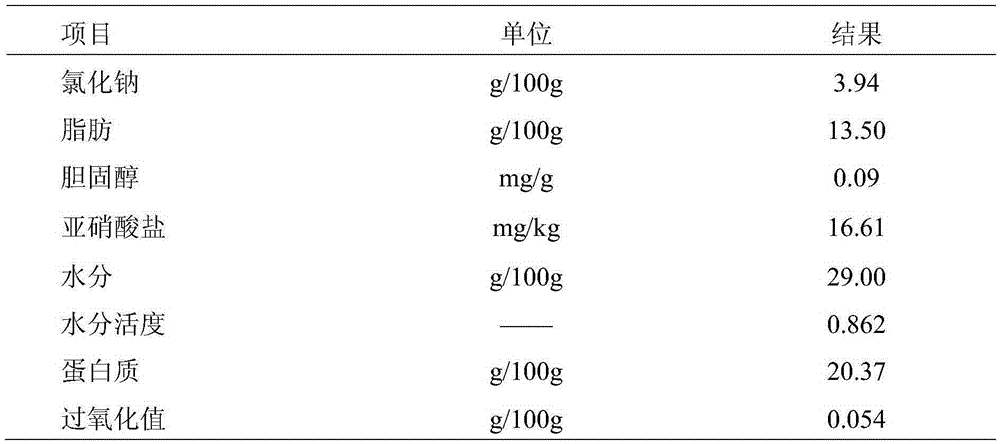

Embodiment 1

[0046] A preparation method of recombined fat meat, the specific steps are as follows:

[0047] (1) Fractional extraction: beat fresh pork fat into a paste, add 2.5 times the weight of pig fat slurry and isopropanol with a mass concentration of 94%, stir and extract at 70°C for 60 minutes, filter, To obtain the pig fat extract; cool the pig fat extract to 16°C and keep it warm for 12 hours, and collect the supernatant; heat the supernatant to above 83°C to completely evaporate the isopropanol to obtain liquid lard I.

[0048] (2) Cholesterol removal: take the quality of liquid lard 1 as a benchmark, add 1.5% β-cyclodextrin and 20% water in liquid lard, heat to 60°C, keep stirring for 70min, centrifuge to obtain low Cholesterol in Liquid Lard II.

[0049] (3) Emulsification: Based on the quality of liquid lard II, in the low-cholesterol liquid lard II, add 2.2% acetylated mono-diglyceride fatty acid esters, 1.8% citric acid fatty acid glycerides, 40% Starch sodium octenyl suc...

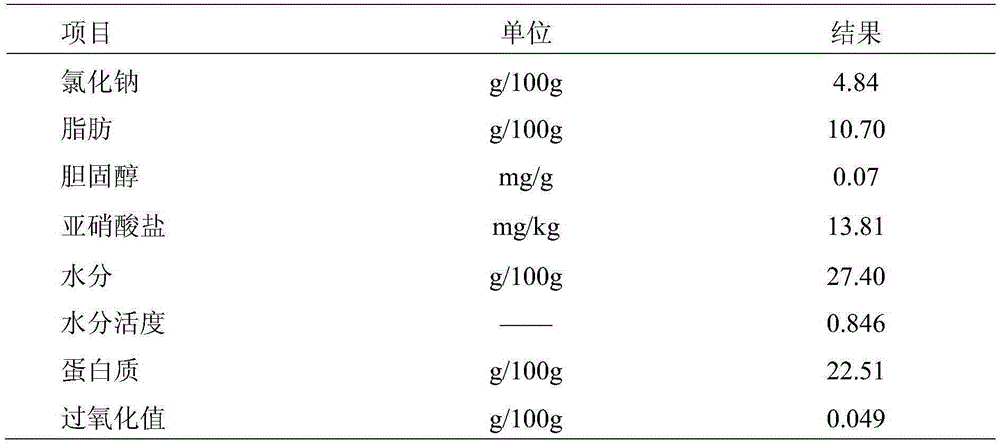

Embodiment 2

[0054] A preparation method of recombined fat meat, the specific steps are as follows:

[0055] (1) Fractional extraction: beat fresh pork fat into a paste, add 1.5 times the weight of pig fat slurry and isopropanol with a mass concentration of 100%, stir and extract at 70°C for 60 minutes, filter, To obtain the pig fat extract; cool the pig fat extract to 16°C and keep it warm for 12 hours, and collect the supernatant; heat the supernatant to above 83°C to completely evaporate the isopropanol to obtain liquid lard I.

[0056] (2) Cholesterol removal: Based on the quality of liquid lard I, add 4% β-cyclodextrin and 40% water to liquid lard I, heat to 60°C, keep stirring for 70min, and centrifuge to obtain Low Cholesterol Liquid Lard II.

[0057] (3) Emulsification: Based on the quality of liquid lard II, add 2% acetylated mono-diglyceride fatty acid esters, 2% citric acid fatty acid glycerides, 50% octene to low-cholesterol liquid lard II Sodium starch succinate, 1.2% xantha...

Embodiment 3

[0062] A preparation method of recombined fat meat, the specific steps are as follows:

[0063] (1) Fractional extraction: heat the lard made from pork fat to above 60°C, and then cool it to 24°C. Insulation, crystallization, and separation; in this way, the temperature is lowered by 3°C each time, heat preservation, crystallization, and separation, and the supernatant is always cooled to 15°C. After the heat preservation produces crystallization, the separated supernatant is liquid lard I.

[0064] (2) Cholesterol removal: Based on the quality of liquid lard I, add 2.5% β-cyclodextrin and 30% water to liquid lard I, heat to 60°C, keep stirring for 70min, and centrifuge to obtain Low Cholesterol Liquid Lard II.

[0065] (3) Emulsification: Based on the quality of liquid lard II, in the low-cholesterol liquid lard II, add 1.8% acetylated mono-diglyceride fatty acid esters, 2.2% citric acid fatty acid glycerides, 60% Starch sodium octenyl succinate, 1.6% xanthan gum, and 4 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com