Compound heat insulating and fresh keeping protection film

A protective film and composite technology, applied in the direction of synthetic resin layered products, flexible slender elements, flexible coverings, etc., can solve the problem that microporous fresh-keeping film cannot achieve tensile resistance, complicated preparation process, and good insurance effect and other problems, to achieve the effect of improving the fresh-keeping effect, good softness, and suitable hole spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

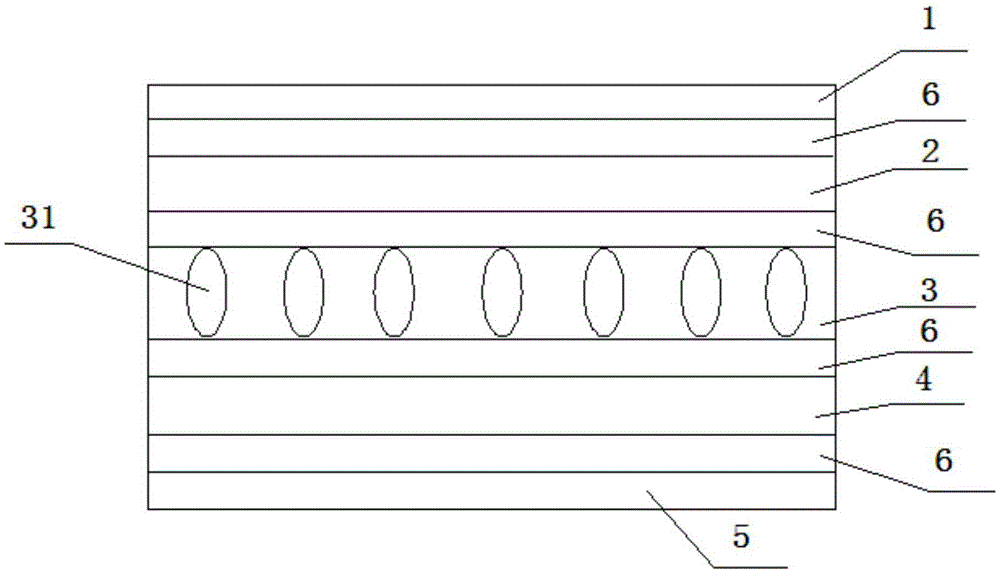

[0023] refer to figure 1 As shown, this embodiment discloses a composite heat-insulating and fresh-keeping protective film, which sequentially includes: a first reflective barrier layer 1, a first woven cloth layer 2, an EPE composite layer 3, a second woven cloth layer 4, a second woven cloth layer Two reflective barrier layers 5, the first reflective barrier layer 1 and the second reflective barrier layer 5 are high-reflectivity aluminum foils, and their thicknesses are equal. In this embodiment, the thickness of the selected aluminum foil is 7 μm, and the aluminum foil is used as the reflective barrier layer, which has a very good high reflectivity, which can improve the heat insulation effect of the plastic wrap.

[0024] Moreover, the first reflective barrier layer 1 , the first woven fabric layer 2 , the EPE composite layer 3 , the second woven fabric layer 4 , and the second reflective barrier layer 5 are all bonded by the PE layer 6 .

[0025] The above-mentioned EPE ...

Embodiment 2

[0029] The structure of the protective film in Example 2 is consistent with that of Example 1, which includes in turn: the first reflective barrier layer 1, the first woven cloth layer 2, the EPE composite layer 3, the second woven cloth layer 4, the second reflective barrier layer Layer 5, the first reflective barrier layer 1 and the second reflective barrier layer 5 are high-reflectivity aluminum foils, and their thicknesses are equal. In this embodiment, the thickness of the aluminum foil is selected to be 20 μm.

[0030] Moreover, the first reflective barrier layer 1 , the first woven fabric layer 2 , the EPE composite layer 3 , the second woven fabric layer 4 , and the second reflective barrier layer 5 are all bonded by the PE layer 6 .

[0031] The above-mentioned EPE composite layer 3 includes 5 layers of EPE layers, the thickness of the above-mentioned EPE composite layer is no more than 2cm, preferably 0.5-2cm, in this embodiment, the above-mentioned EPE layers are fix...

Embodiment 3

[0035] The structure of the protective film in Example 3 is consistent with that of Example 1, which includes in turn: the first reflective barrier layer 1, the first woven fabric layer 2, the EPE composite layer 3, the second woven fabric layer 4, the second reflective barrier layer Layer 5, the first reflective barrier layer 1 and the second reflective barrier layer 5 are high-reflectivity aluminized PET films, and their thicknesses are equal. In this embodiment, the thickness of the aluminized PET film is selected to be 12 μm.

[0036] Moreover, the first reflective barrier layer 1 , the first woven fabric layer 2 , the EPE composite layer 3 , the second woven fabric layer 4 , and the second reflective barrier layer 5 are all bonded by the PE layer 6 .

[0037] The above-mentioned EPE composite layer 3 includes 5 layers of EPE layers, the thickness of the above-mentioned EPE composite layer is no more than 2cm, preferably 0.5-2cm, in this embodiment, the above-mentioned EPE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com