High-intensity waterproof breathable multilayer composite material and preparation method thereof

A multi-layer composite material, waterproof and breathable technology, applied in the field of building materials, can solve problems such as no high-strength waterproof and moisture-permeable composite materials, no polyolefins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

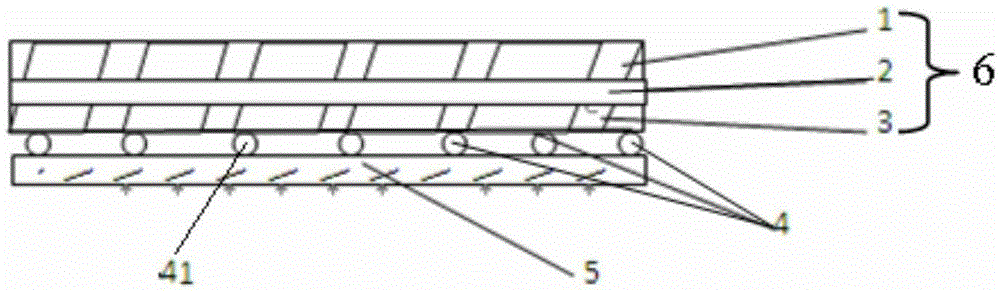

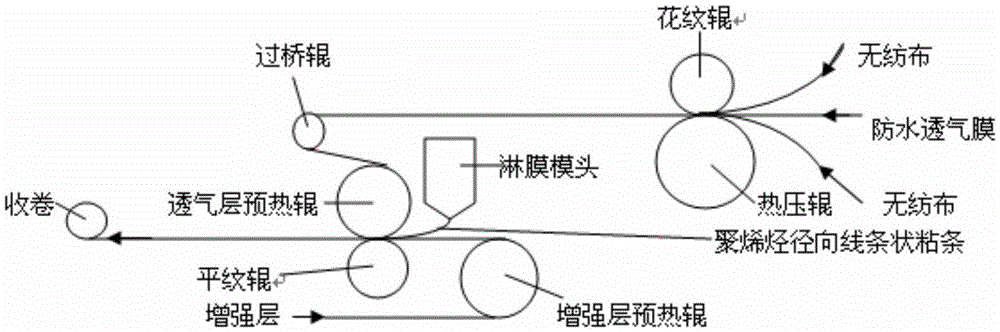

[0027] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with examples and test data.

[0028] Example 1

[0029] Polyethylene (LLDPE, Maoming Petrochemical / DNDA-7144) 60Kg, polypropylene (s2040, Shanghai Secco Petrochemical) 30Kg, POE (POE8200, Dow) 8.5Kg, heat stabilizer (B215, Beijing Yanlian Chemical Factory) 0.5 Kg, ethylene bis stearamide 0.8Kg, polysuccinic acid (4-hydroxy-2,2,6,6-tetramethyl-1-piperidine ethanol) ester 0.2Kg after premixing in a high-speed premixer , using a twin-screw extruder to extrude and granulate to obtain a polyolefin mixed material masterbatch for polyolefin melting and radial line bonding.

[0030] The reinforcing layer is polypropylene split silk woven cloth (50g / m 2 , Laiwu Baoli Engineering Materials Co., Ltd.). Split film yarn woven fabric is made of polypropylene split film flat yarn. It consists of two sets of parallel yarns (the shape of which is a flat ...

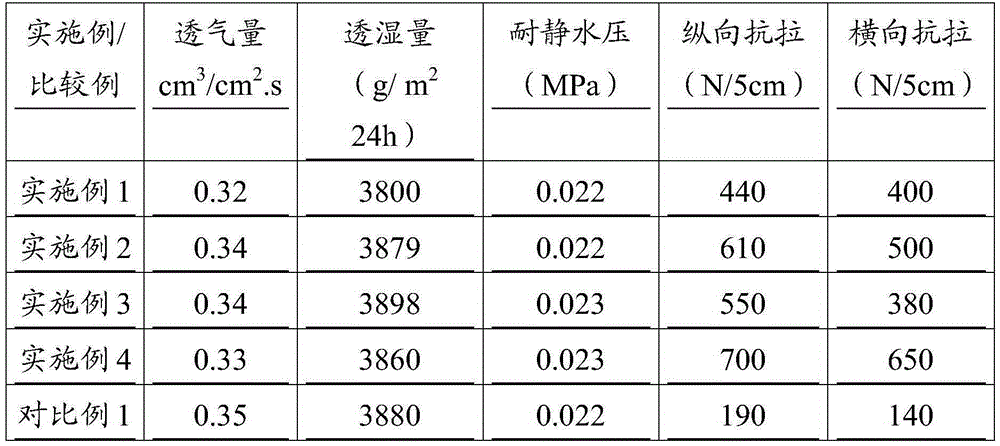

Embodiment 2

[0034] The preparation process and conditions of the high-strength multi-layer waterproof and breathable composite material in this example are the same as those in Example 1. The difference is that the woven fabric of the reinforcing layer is polypropylene filament plain weave (522-62×64, Shanghai Tianyuan Filtration Equipment Co., Ltd.). The test properties of the composite materials are shown in Table 1.

Embodiment 3

[0036] The preparation process and conditions of the high-strength multi-layer waterproof and breathable composite material in this example are the same as those in Example 1. The difference is that the woven fabric of the reinforcing layer is polyethylene woven fabric (50g / m 2 , Ningbo Jiashimei Plastic Co., Ltd.). The test properties of the composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com