Filter system applied to pickling sludge leachate treatment

A filter system and pickling sludge technology, applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as incomplete treatment, environmental pollution, etc. Achieve the effect of improving processing capacity and impact resistance, and avoiding the effect of impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

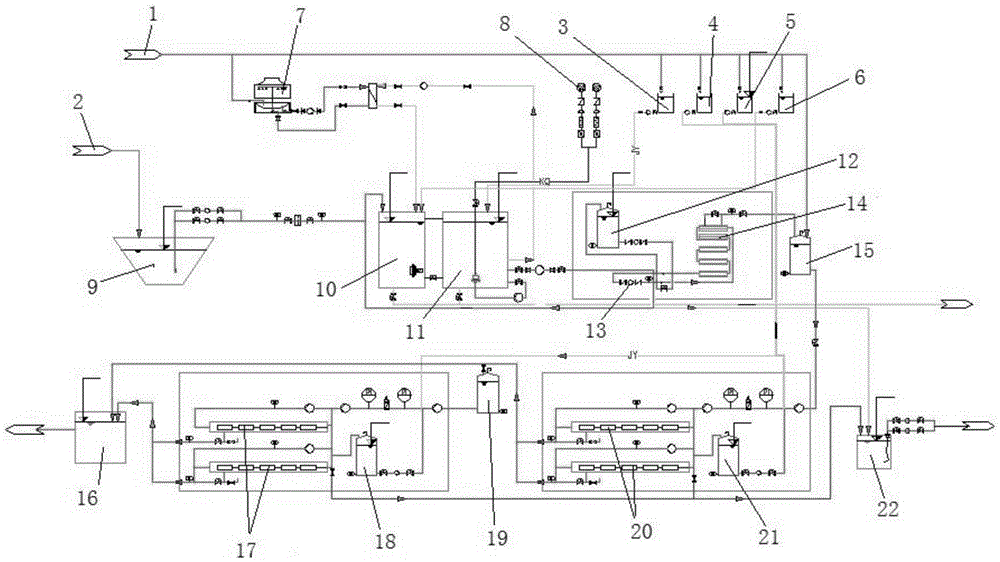

[0015] like figure 1 A filtration system for pickling sludge leachate treatment is shown, which is composed of UF membrane filtration module, RO membrane filtration module and NF membrane filtration module; UF membrane filtration module includes tap water inlet 1, and tap water Water inlet 1 is connected to defoaming agent mixing tank 3, antifouling agent mixing tank 4, acid preparation tank 5, carbon source preparation tank 6, liquid mixing tank 7, UF cleaning tank 15, and denitrification tank 10 connected to liquid mixing tank 7 , and the leachate inlet 2 connected with the adjustment tank 9, and the adjustment tank 9 connected with the denitrification tank 10, the nitrification tank 11, and the air compressor 8 connected with the nitrification tank 11, and the UF cleaning tank 15 Connected UF membrane filter element 14, and UF cleaning tank 12 and UF circulation pump 13 respectively connected with UF membrane filter element 14, wherein, UF cleaning tank 12 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com