A method for treating landfill leachate concentrate by membrane method

A landfill leachate and treatment method technology, applied in the field of landfill leachate treatment, can solve the problems of low biodegradability of pollutants, high operating costs, membrane pollution, etc., and achieve the goal of improving treatment efficiency, improving treatment effect, and high treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

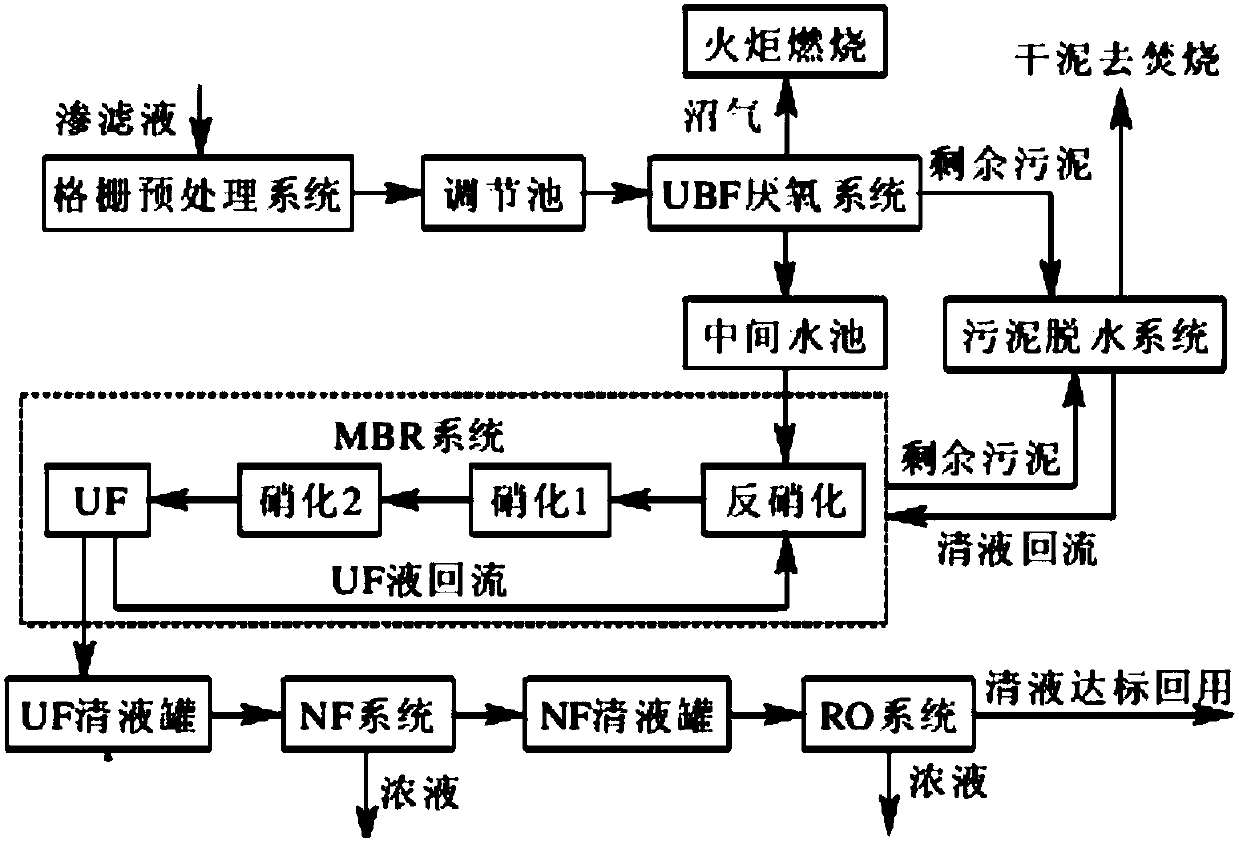

[0033] Typical leachate treatment and nanofiltration, reverse osmosis concentrate production process see figure 1 . The leachate enters the regulating tank through the grid pretreatment system, and then enters the UBF anaerobic system. The anaerobic effluent enters the intermediate pool, and the effluent of the intermediate pool enters the denitrification tank and the two-stage aerobic nitrification tank in turn. The effluent from the nitrification tank enters the tubular ultrafiltration membrane system. The ultrafiltration concentrate is returned to the denitrification tank. The ultrafiltrate clear liquid enters the clear liquid tank and then enters the nanofiltration system to produce nanofiltration concentrated liquid and clear liquid. The nanofiltration clear liquid can be discharged directly, or collected by the nanofiltration clear liquid tank and then injected into the reverse osmosis system to generate Reverse Osmosis Concentrate and Reverse Osmosis Supernatant.

[...

Embodiment 2

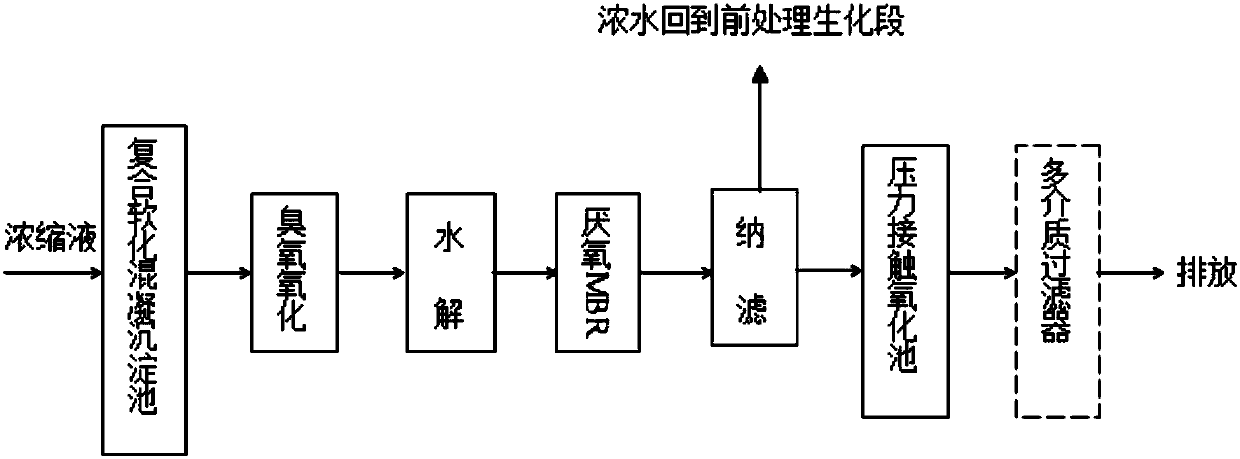

[0036] The landfill leachate film concentrated solution that embodiment 1 is obtained is first through composite softening coagulation sedimentation tank, and composite softening coagulation sedimentation tank is made up of 3 grades of reaction tanks and sedimentation tanks, and the 1st grade reaction tanks add sodium carbonate, sodium carbonate The total moles of dosing is 1 times of the total moles of calcium and magnesium ions in the wastewater, 200mg / L polyaluminum chloride is added to the second reaction tank, and 2mg / L polyacrylamide polymer flocculant is added to the third reaction tank PAM, the total reaction time is 30min, and then enters the sedimentation tank for sedimentation to reduce the hardness of wastewater and remove COD. The total residence time of wastewater in the compound softening coagulation sedimentation tank is 3h.

[0037] The effluent from the sedimentation tank enters the ozone oxidation reactor for treatment. The ozone oxidation reactor includes an...

Embodiment 3

[0043] The landfill leachate film concentrate obtained in Example 1 first passes through the composite softening coagulation sedimentation tank, the composite softening coagulation sedimentation tank is composed of a 4-stage reaction tank and a sedimentation tank, and sodium hydroxide is added to the 1st to 2nd-stage reaction tanks. The total number of moles of sodium hydroxide added is 0.8 times the total number of moles of calcium and magnesium ions in the wastewater, 500mg / L polyferric sulfate is added to the second-stage reaction pool, and 2mg / L polyacrylamide is added to the third-stage reaction pool. Molecular flocculant PAM, with a total reaction time of 60 minutes, then enters the sedimentation tank for sedimentation to reduce the hardness of wastewater and remove COD. The total residence time of wastewater in the compound softening coagulation sedimentation tank is 5 hours.

[0044] The effluent from the sedimentation tank enters the ozone oxidation reactor for treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com