Theasaponin extract and preparation method thereof

A technology of tea saponins and extracts, applied in the preparation of anti-inflammatory and hypolipidemic health food or medicines, in the field of triterpenoid saponins, can solve problems such as hindering the popularization and application of extracts, difficult quality control, weak water solubility and the like , to achieve the effect of small dosage, improved physical and chemical properties, and clear composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

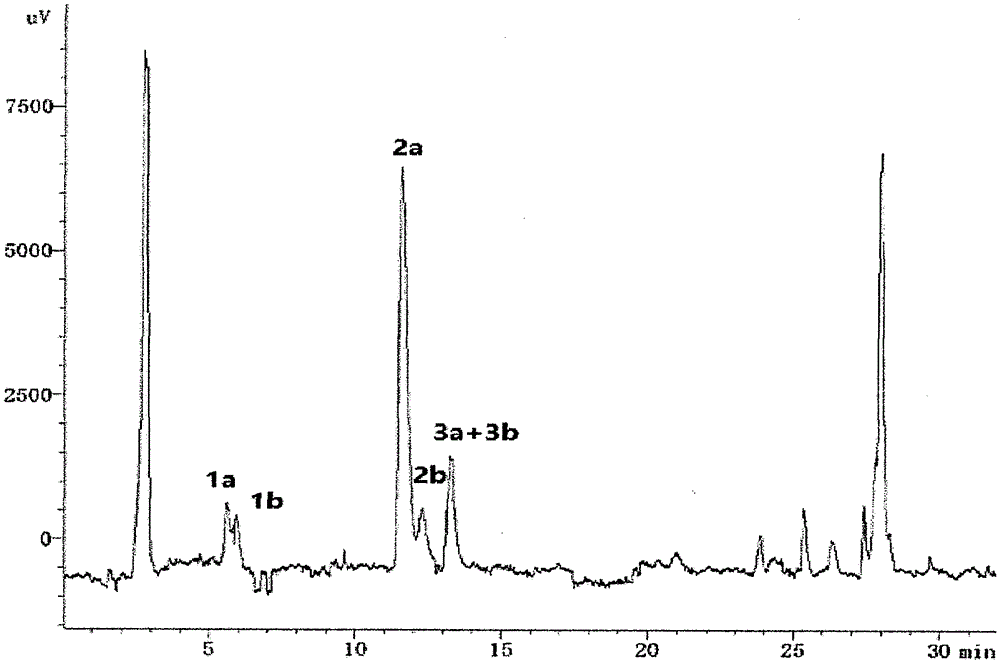

[0024] Example 1: Preparation of Camellia Seed Saponins

[0025] The cake obtained from oil tea seed (Camelliaoleifera, batch 20120901, collected from Guangnan, Yunnan) is selected.

[0026] (1) Weigh 800 g of camellia seed cake, pulverize and add 10 times the amount of 80% ethanol to soak overnight, reflux and extract twice for 2 hours each time, and concentrate to about 3L under reduced pressure. Take 2L of the concentrated solution and absorb it on AB-8 macroporous adsorption resin column (15×60cm, column volume 2L), followed by water (8L), 10% ethanol (8L), 30% ethanol (8L), 75% ethanol ( 8L) eluted, and the 75% ethanol eluted part was concentrated under reduced pressure and dried to obtain 40.9 g of total saponin CSA.

[0027] (2) Take 10g of CS-A, add 100ml of 2mol / L NaOH solution, hydrolyze at 95℃ for 5h, neutralize with 5mol / L HCl to pH 4-6, load AB-8 macroporous adsorption resin (column volume 400ml), and then use water (1.6L) ), 75% ethanol (1.6L), the 75% ethanol eluate ...

Embodiment 2

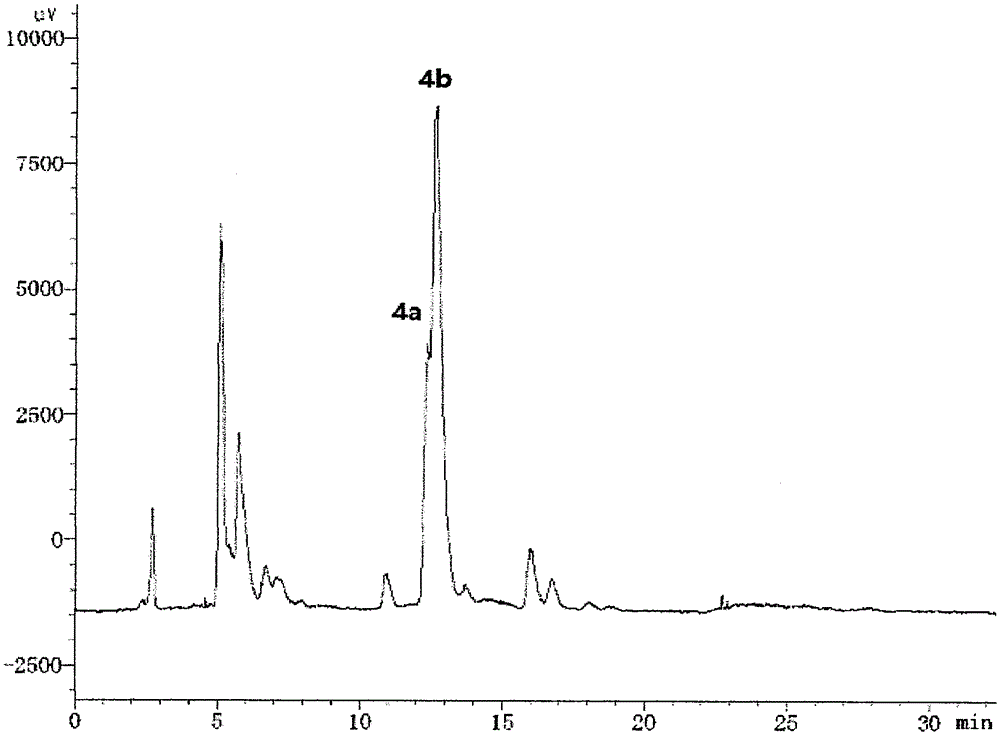

[0038] Example 2: Preparation of Camellia oleifera Root Saponins

[0039] The root of Camellia oleifera (batch 20110901, collected from Qichun County, Hubei Province) was selected and prepared with reference to Example 1.

[0040] (1) Weigh 100g of Camellia oleifera root, pulverize and add 10 times the amount of 60% ethanol to soak overnight, reflux and extract twice, 1.5h each time, concentrate to 500mL under reduced pressure, and put on AB-8 macroporous adsorption resin column (column volume 300mL ) After adsorption, eluted with water (5L), 30% ethanol (1L), 60% ethanol (1L), and the 60% ethanol eluted part was concentrated under reduced pressure and dried to obtain 21.4g of total saponin CSA.

[0041] (2) Take 10g of CSA, add 100ml of 2mol / L NaOH solution, hydrolyze at 95°C for 5 hours, neutralize with 5mol / L HCl to pH 4-6, load AB-8 macroporous adsorption resin (column volume 400ml), and then water (1.6L), 75% ethanol (1.6L), the 75% ethanol eluate was collected, concentrated un...

Embodiment 3

[0044] Example 3: Preparation of tea seed saponin

[0045] The seeds of tea (Camelliasinensis, batch 20131001, collected from Guangnan, Yunnan) were selected and prepared with reference to Example 1.

[0046] (1) Weigh 100g of tea seeds, pulverize and add 10 times the amount of 60% ethanol to soak overnight, reflux and extract twice, 1.5h each time, concentrate to 500mL under reduced pressure, and put on AB-8 macroporous adsorption resin column (column volume 300mL ) After adsorption, eluted with water (5L), 30% ethanol (1L) and 60% ethanol (1L) successively, and the 60% ethanol eluted part was concentrated under reduced pressure and dried to obtain 27g of total tea saponin CSA.

[0047] (2) Take 10g of CSA, add 100ml of 2mol / L NaOH solution, hydrolyze at 95°C for 5 hours, neutralize with 5mol / L HCl to pH 4-6, load AB-8 macroporous adsorption resin (column volume 400ml), and then water (1.6L), 75% ethanol (1.6L), the 75% ethanol eluate was collected, concentrated under reduced press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com