Method for preparing functionalized crosslinked monodisperse polymer microspheres by one-step dispersion polymerization

A technology of dispersion polymerization and functionalization, which is applied in the field of preparation of functionalized cross-linked monodisperse polymer microspheres, can solve the problems of limited application range, low degree of cross-linking and functionalization of microspheres, and achieve efficient and efficient preparation process. Ease of large-scale preparation and popularization, and the effect of energy-saving preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

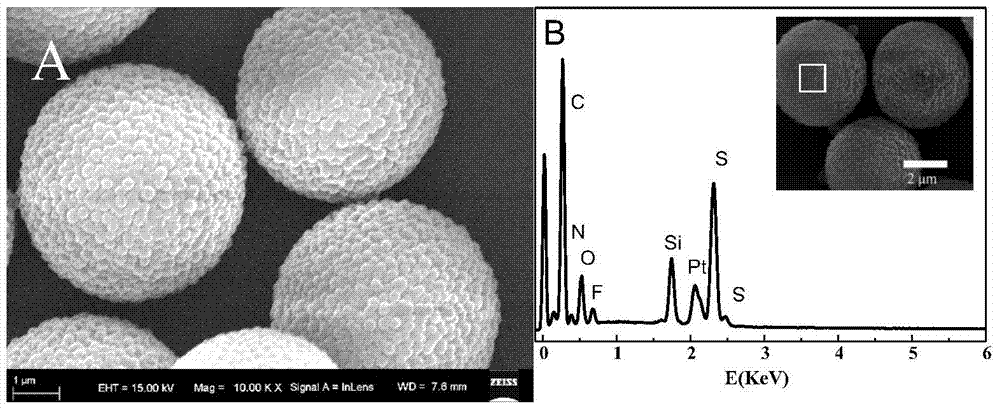

[0028] Example 1: Preparation of alkyne-functionalized, cross-linked, monodisperse polymer microspheres

[0029] 50g of ethanol, 1g of distilled water and 1g of PVP were dispersed uniformly by ultrasonic at room temperature to make a uniform continuous phase; Propyl ester is mixed evenly to make a uniform transparent oil phase. Add the prepared dispersed phase into a three-neck flask equipped with stirring, start the stirring and control the rotation speed at 100 rpm, add the prepared oil phase into the three-necked flask, and react at room temperature for 4 hours to obtain microspheres. The obtained microspheres were washed three times with distilled water, filtered, and dried in air for 24 hours to obtain dry, highly cross-linked, alkyne-functionalized polymer microspheres.

example 2

[0030] Example 2: Preparation of alkyne-functionalized, cross-linked, monodisperse polymer microspheres

[0031] 50g ethanol, 50g distilled water and 1g PVP were dispersed uniformly by ultrasonic at room temperature to make a uniform continuous phase; Propyl ester is mixed evenly to make a uniform transparent oil phase. Add the prepared dispersed phase into a three-necked flask equipped with stirring, start stirring and control the rotation speed at 400 rpm, add the prepared oil phase into the three-necked flask, and react at room temperature for 8 hours to obtain microspheres. The obtained microspheres were washed three times with distilled water, filtered, and dried in air for 24 hours to obtain dry, highly cross-linked, alkyne-functionalized polymer microspheres.

example 3

[0032] Example 3: Preparation of fluorescently labeled, crosslinked, monodisperse polymer microspheres

[0033] 50g ethanol, 1g distilled water and 1g PVP were uniformly dispersed at room temperature by ultrasonic to make a uniform continuous phase; Ester fluorescein is mixed evenly to make a uniform transparent oil phase. Add the prepared dispersed phase into a three-necked flask equipped with stirring, start stirring and control the rotation speed at 400 rpm, add the prepared oil phase into the three-necked flask, and react at room temperature for 8 hours to obtain microspheres. The obtained microspheres were washed three times with distilled water, filtered, and dried in air for 24 hours to obtain dry, highly cross-linked, and fluorescently labeled polymer microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com