PMA-EVAL high-strength cable sealing sheath and preparation method thereof

A cable sealing and high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of cracking, mechanical properties of the sealing sheath, and plummeting performance of the sealing sheath.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a kind of preparation method of PMA-EVAL high-strength cable sealing sheath, and this preparation method comprises:

[0015] 1) water glass is mixed with sulfuric acid solution to form hydrogel;

[0016] 2) Soak bentonite in hydrochloric acid solution for activation treatment, then filter to get filter cake to make modifier;

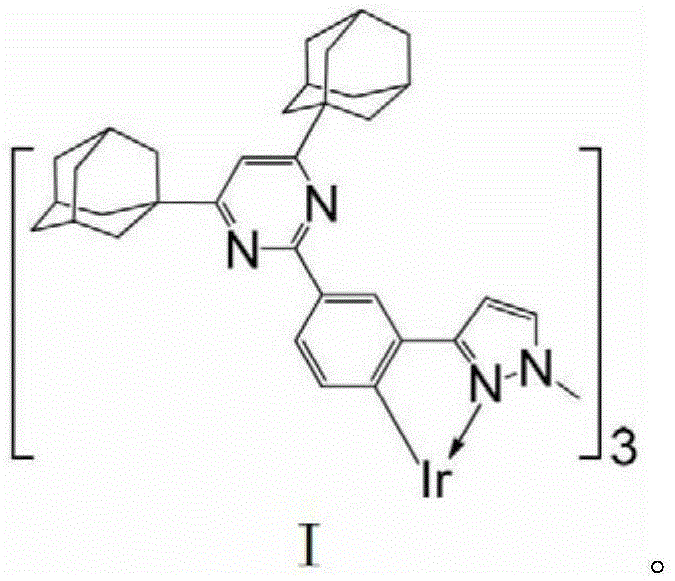

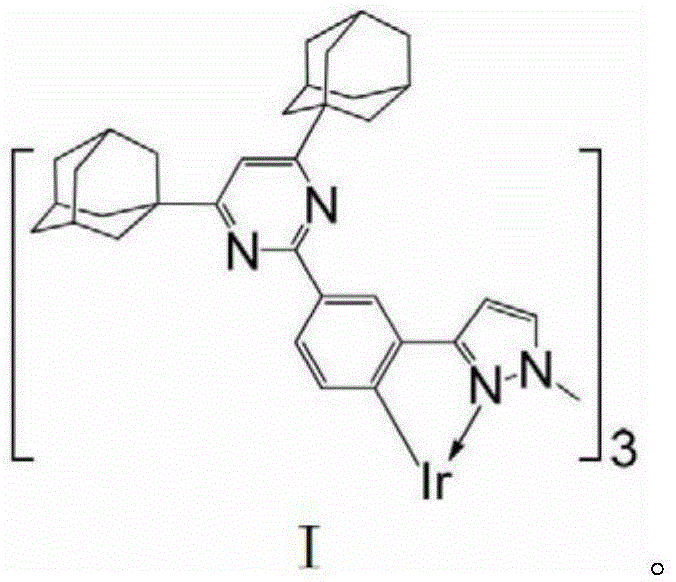

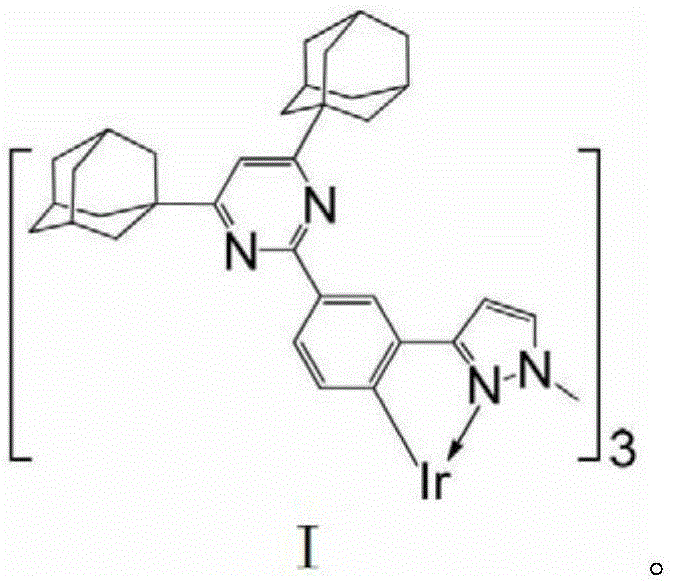

[0017] 3) PMA (polymethyl acrylate), EVAL (ethylene-vinyl alcohol copolymer), the complex shown in formula (I), limestone, butylene phthalate, hydrazine, sinigrin, diborane Alkanes, glycerol, triallyl cyanurate, 2-thiol benzothiazole, hydrogel and modifier mixing, cooling molding to make PMA-EVAL high-strength cable sealing sheath;

[0018]

[0019] In step 1) of the present invention, the consumption of each material can be selected in a wide range, but in order to make the obtained cable sealing sheath have more excellent mechanical properties, corrosion resistance and pressure resistance performance, preferably, in I...

Embodiment 1

[0031] 1) At 40° C., water glass and sulfuric acid solution (concentration: 18% by weight) were mixed according to the weight ratio of 400 for 2.5 hours to form a hydrogel;

[0032] 2) At 80°C, mix bentonite and hydrochloric acid solution (concentration: 27% by weight) according to the weight ratio of 100:230 for 4 hours to activate the bentonite, and then filter the filter cake to obtain the modifier;

[0033] 3) PMA (weight-average molecular weight is 10000), EVAL (weight-average molecular weight is 7000), the complex compound shown in formula (I), limestone, butylene phthalate, hydrazine, sinigrin, ethyl boron Alkanes, glycerol, triallyl cyanurate, 2-mercaptobenzothiazole, hydrogels and modifiers according to 100:40:2.5:50:18:7:9:5:17: 22:13:24:25 mixing and kneading at 218°C for 70mim, cooling and molding at 13°C to obtain PMA-EVAL high-strength cable sealing sheath A1.

Embodiment 2

[0035] 1) At 35° C., water glass and sulfuric acid solution (concentration: 15% by weight) were mixed according to a weight ratio of 300 for 2 hours to form a hydrogel;

[0036] 2) At 78°C, mix bentonite and hydrochloric acid solution (concentration: 25% by weight) for 3 hours according to the weight ratio of 100:200 to activate the bentonite, and then filter the filter cake to obtain the modifier;

[0037] 3) PMA (weight-average molecular weight is 9000), EVAL (weight-average molecular weight is 5000), complex compound shown in formula (I), limestone, butylene phthalate, hydrazine, sinigrin, diborane Alkane, glycerol, triallyl cyanurate, 2-mercaptobenzothiazole, hydrogel and modifier according to 100:35:1.5:35:12:5:7:3:14: 15:10:20:20 mixing and kneading at 215°C for 60mim, cooling and molding at 10°C to obtain PMA-EVAL high-strength cable sealing sheath A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com