Wear-resistant enhanced PPO/HIPS material and preparation method therefor

A raw material and resin technology, applied in the field of wear-resistant reinforced PPO/HIPS materials and their preparation, can solve the problems of poor wear resistance and strength, and achieve the effects of excellent wear resistance, excellent mechanical properties and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

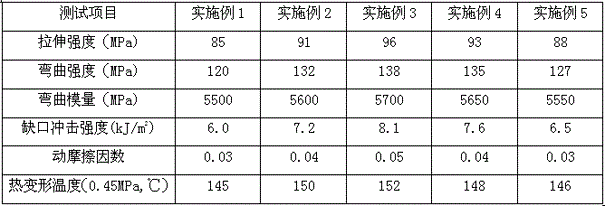

Examples

Embodiment 1

[0062] A wear-resistant reinforced PPO / HIPS material, which is made up of the following raw materials in parts by weight:

[0063] HIPS resin 20 parts

[0064] 5 parts of PPO resin

[0065] 3 parts nitrile rubber

[0066] 3 parts of TPU resin

[0067] 10 parts glass fiber

[0068] 10 parts of aramid fiber

[0069] Molybdenum disulfide 3 parts

[0070] 3 parts calcium sulfate whiskers

[0071] 1 part polytetrafluoroethylene

[0072]0.5 parts of coupling agent

[0073] Lubricant 0.5 parts

[0074] Antioxidant 0.2 part.

[0075] The HIPS resin is a high-impact polystyrene with a melt index of 1 g / 10 min under the test conditions of 200° C. and 5 kg; the TPU resin is a thermoplastic polyurethane elastomer with a Shore A hardness of 60.

[0076] The glass fiber is a chopped alkali-free glass fiber with a single filament diameter of 10 μm; the aramid fiber is a chopped aramid 1414 fiber with a single filament diameter of 10 μm.

Embodiment 2

[0085] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0086] A wear-resistant reinforced PPO / HIPS material, which is made up of the following raw materials in parts by weight:

[0087] HIPS resin 25 parts

[0088] 10 parts of PPO resin

[0089] 4 parts nitrile rubber

[0090] 4 parts of TPU resin

[0091] 15 parts glass fiber

[0092] 11 parts of aramid fiber

[0093] Molybdenum disulfide 3 parts

[0094] 3 parts calcium sulfate whiskers

[0095] 3 parts polytetrafluoroethylene

[0096] 0.8 parts of coupling agent

[0097] Lubricant 0.6 parts

[0098] 0.4 part of antioxidant.

[0099] The HIPS resin is a high-impact polystyrene with a melt index of 2 g / 10 min under the test conditions of 200° C. and 5 kg; the TPU resin is a thermoplastic polyurethane elastomer with a Shore A hardness of 70.

[0100] The glass fiber is a chopped E-glass fiber with a single filament diameter of 11 μm; the aramid fiber is a chopped aramid 1414 fiber w...

Embodiment 3

[0105] The difference between this embodiment and the above-mentioned embodiment 1 is:

[0106] A wear-resistant reinforced PPO / HIPS material, which is made up of the following raw materials in parts by weight:

[0107] HIPS resin 30 parts

[0108] 20 parts of PPO resin

[0109] 5 parts nitrile rubber

[0110] TPU resin 5 parts

[0111] 20 parts glass fiber

[0112] 12 parts of aramid fiber

[0113] Molybdenum disulfide 6 parts

[0114] 6 parts calcium sulfate whiskers

[0115] 5 parts polytetrafluoroethylene

[0116] 1 part coupling agent

[0117] Lubricant 0.8 parts

[0118] 0.5 part of antioxidant.

[0119] The HIPS resin is a high-impact polystyrene with a melt index of 3 g / 10 min under the test conditions of 200° C. and 5 kg; the TPU resin is a thermoplastic polyurethane elastomer with a Shore A hardness of 75.

[0120] The glass fiber is a chopped E-glass fiber with a single filament diameter of 12 μm; the aramid fiber is a chopped aramid 1414 fiber with a sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com