Liquid mulching film and preparation method thereof

A technology of liquid mulch and oil solution, which is applied in botany equipment and methods, horticulture, plant protection covers, etc., can solve the problems of complicated process, poor film formation, and poor degradation performance of mulch, and achieve good degradation performance, Good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

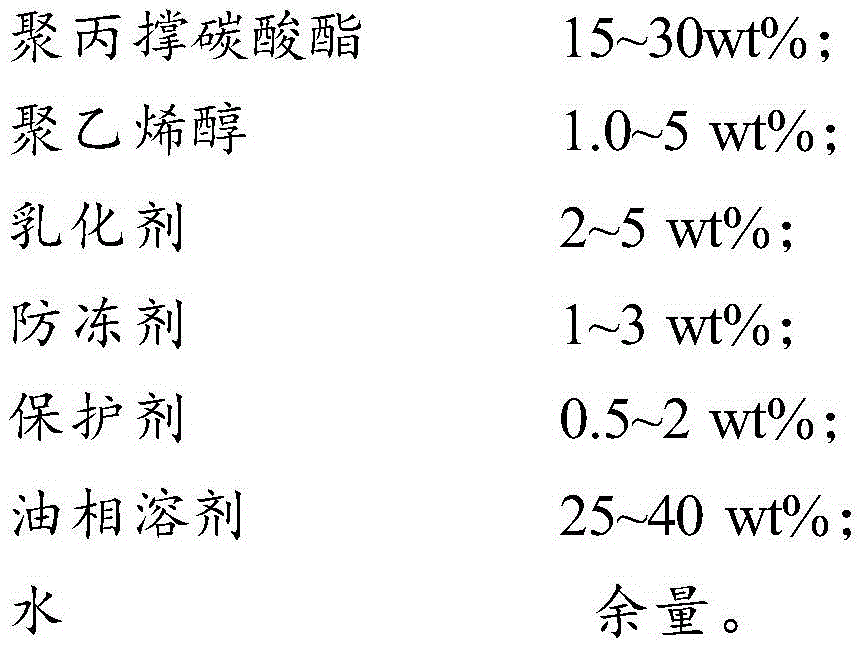

[0049] The present invention provides a method for preparing a liquid mulch film as described in the above technical solution, comprising:

[0050] A) mixing polypropylene carbonate with an oil phase solvent, stirring, mixing with an emulsifier, stirring to obtain an oil solution;

[0051] Mix polyvinyl alcohol and protective agent with water to obtain an aqueous solution;

[0052] B) The aqueous solution is added to the oil solution, mixed with antifreeze, stirred, and emulsified to obtain a liquid mulch film.

[0053] In the invention, polypropylene carbonate is mixed with an oil phase solvent, stirred, mixed with an emulsifier, and stirred to obtain an oil solution.

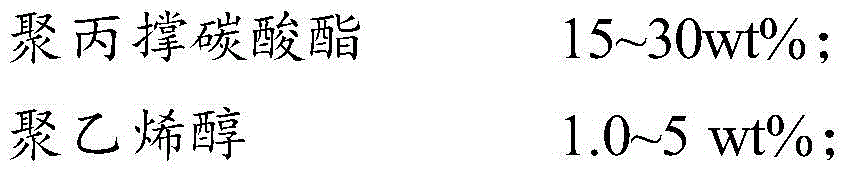

[0054] In the present invention, firstly, the polypropylene carbonate and the oil phase solvent are mixed and stirred to obtain a mixed solution. The mass ratio of the polypropylene carbonate to the oil phase solvent is (15-30): (25-40); preferably (17-28): (28-38). The mass percentage of the mixed polyprop...

Embodiment 1

[0087] Dissolve 32 grams of PPC (Mn=32,000) in 70 mL of dimethyl carbonate solution, stir at 40°C for 30 minutes at a stirring speed of 400 rpm, add 4 grams of Span 80 and 2 grams of Tween 80 emulsifier, Continue stirring to form an oil solution, dissolve 2.5 grams of polyvinyl alcohol 1788 and 0.5 grams of sodium carboxymethylcellulose in 80 mL of water, slowly add the aqueous solution to the above oil solution under stirring, then add 3 grams of ethylene glycol and continue stirring for 5 Minutes, using a high-speed shearing machine at a speed of 12000rpm to emulsify for 5 minutes, centrifuge at 2500rpm for 30 minutes without stratification, and obtain a liquid mulch film. The liquid mulch can be completely degraded in 270 days. The performance of the prepared mulch is measured by the assay method of the present invention. The results are shown in Table 1. Table 1 shows the properties of the liquid mulch prepared by the embodiments of the present invention and comparative exa...

Embodiment 2

[0089] Dissolve 35 grams of PPC (Mn=53,000) in 50 mL of dimethyl carbonate solution, stir at 50°C for 50 minutes at a stirring speed of 500 rpm, add 5 grams of Tween 80, 3 grams of octadecyltri Methyl ammonium chloride, continue stirring to form an oil solution, dissolve 2 grams of polyvinyl alcohol 1788 and 0.5 grams of sodium carboxymethylcellulose in 60 mL of water, slowly add the aqueous solution to the oil solution, then add 2.5 grams of glycerin and continue stirring After 5 minutes, use a high-speed shearing machine with a speed of 8000rpm to emulsify for 10 minutes, and centrifuge at 2500rpm for 30 minutes without delamination to obtain a liquid mulch film. The liquid mulch can be completely degraded in 280 days. The performance of the prepared mulch is measured by the assay method of the present invention. The results are shown in Table 1. Table 1 shows the properties of the liquid mulch prepared by the embodiments of the present invention and comparative examples. Me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com