Inkjet printing acidic ink suitable for industrial nozzles and preparation method thereof

An inkjet printing and acid ink technology, applied in the ink field, can solve the problems of acid ink versatility, poor smooth performance, hindering the popularization and application of head acid ink, poor ink stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

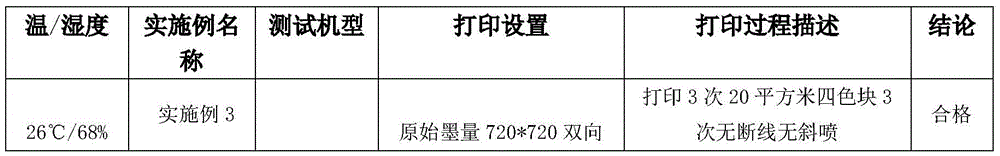

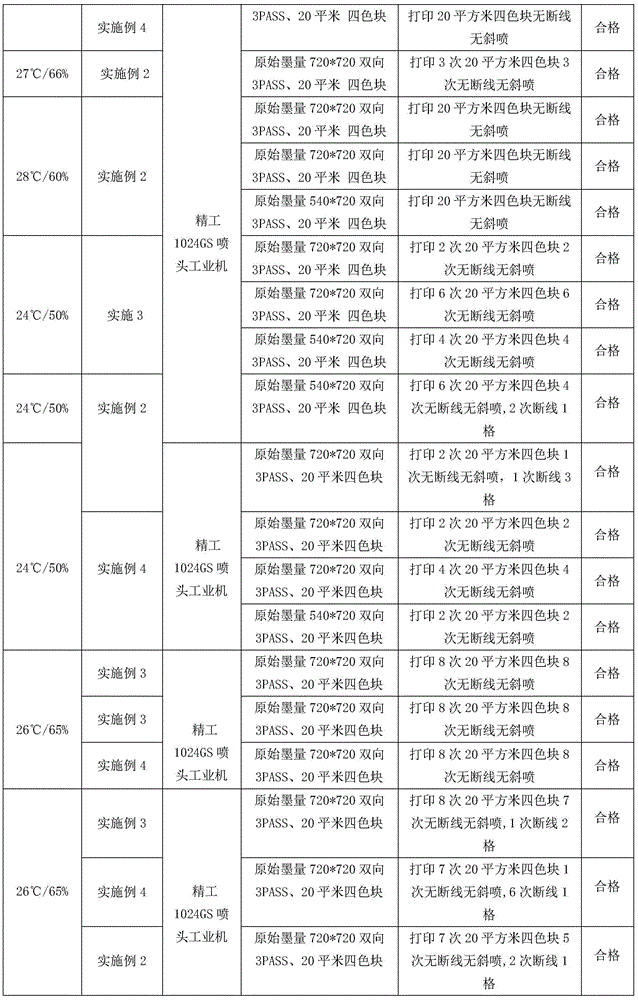

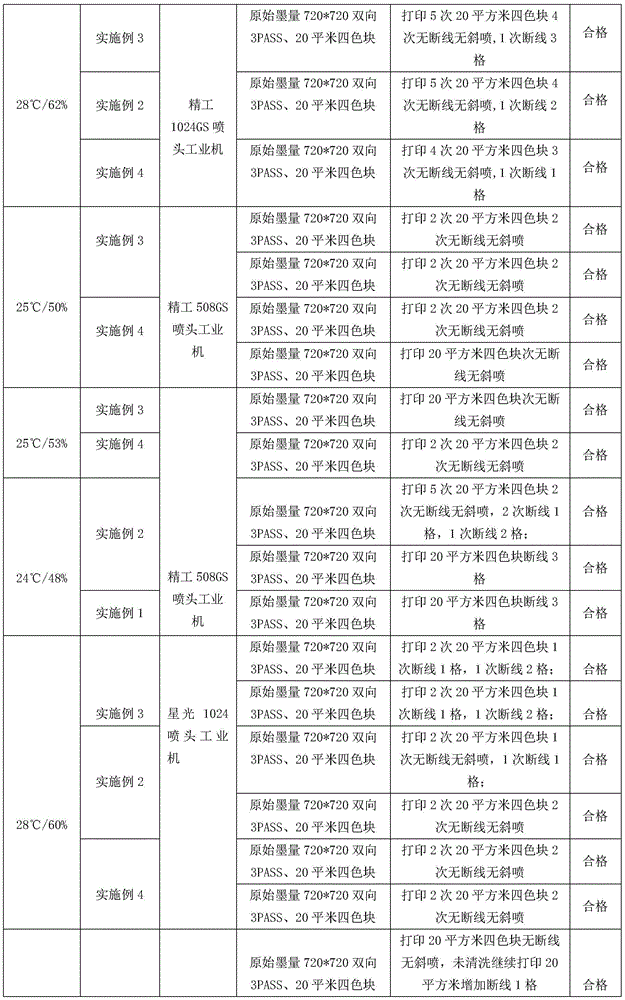

Examples

Embodiment 1

[0021] Weigh 45.6 parts by mass of deionized water, 0.1 parts by mass of defoamer SUFYNOLDF-110D, 0.7 parts by mass of gas chemical surfactant 465, 0.3 parts by mass of Nissin Chemical's surfactant E1010, 0.1 parts by mass Triethanolamine, 0.1 parts by mass of 1,2-benzisothiazolin-3-one, 15 parts by mass of caprolactam, 18 parts by mass of ethylene glycol, 5 parts by mass of 2-pyrrolidone, 2 parts by mass of amino acid humectants , 0.1 parts by mass of dithiocarbamate derivatives, 13 parts by mass of acid black 172 were put into a container and stirred, and stirred at a high speed of 500 rpm for 60 minutes, filtered the stirred material, and used sequentially with a pore size of 1.0 μm Filter element, 0.45μm filter element, 0.22μm filter element perform 3-stage filtration. And the ink is degassed, and the oxygen content is required to be below 3.0ppm to obtain the finished acidic black ink.

Embodiment 2

[0023] Weigh 43.35 parts by mass of deionized water, 0.1 parts by mass of defoamer 104E, 1 part by mass of gas chemical surfactant 485, 0.3 parts by mass of Nissin Chemical's surfactant EXP.4300, 0.05 parts by mass Lithium hydroxide, 0.1 parts by mass of 1,2-benzisothiazolin-3-one, 20 parts by mass of caprolactam, 18 parts by mass of dipropylene glycol, 2 parts by mass of diethylene glycol, 2 parts by mass of amino acid humectants , 0.1 parts by mass of dithiocarbamate derivatives, 2 parts by mass of C.I. Acid Blue 180 are put into a container and stirred at a high speed of 500rpm for 60 minutes, the stirred material is filtered, and the pore size is 1.0 3-stage filtration with μm filter element, 0.45μm filter element, and 0.22μm filter element. And the ink is degassed, and the oxygen content is required to be below 3.0ppm to obtain the finished acidic blue ink.

Embodiment 3

[0025] Weigh 20 parts by mass of deionized water, 0.1 parts by mass of antifoaming agent 104E, 0.1 parts by mass of gas chemical surfactant 420, 0.3 parts by mass of Dow Chemical surfactant EH6, 0.3 parts by mass of Japanese letter Chemical surfactant EXP.4300, 0.1 mass parts of 3-morpholine propanesulfonic acid, 0.1 mass parts of 4-chloro-3-methylphenol, 1 mass part of polyether polyol, 22 mass parts of propylene glycol, 21 parts by mass of ethylene glycol, 2 parts by mass of 1,6-hexanediol, 1 part by mass of amino acid humectant, 0.1 parts by mass of dithiocarbamate derivatives, 3 parts by mass of C.I. acid red 131 was put into a container and stirred, and stirred at a high speed of 500rpm for 60 minutes, and the stirred material was filtered, and three-stage filtration was performed using a filter element with a pore size of 1.0 μm, a filter element of 0.45 μm, and a filter element of 0.22 μm in sequence. And the ink is degassed, and the oxygen content is required to be bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com