Preparation method for nano-particles with metal-carbon core-shell structures

A nanoparticle and carbon core-shell technology, applied in the field of nanomaterials, can solve the problems of high energy consumption, high cost, and alkaline waste liquid, and achieve the effects of simple preparation process, improved excitation efficiency, and enhanced fluorescence of carbon shells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing metal-carbon core-shell nanoparticle, comprising the following steps:

[0026] Step 1: Add metal target Cr (purity ≥ 99.99%) to ethanol solution, pass in argon gas, and use a laser to ablate the metal target under the stirring condition of 80-90rpm to obtain a laser ablation product;

[0027] Step 2: Add the laser ablation product obtained in Step 1 to a 5v / v% sulfuric acid solution, pass through argon, stir and react at 300rpm at 70°C for 15min, and cool to room temperature to obtain the product.

[0028] The ablation process in step 1 is carried out in a quartz container; the laser emitted by the laser has a wavelength of 1064 nm, a pulse duration of 10 ns, a voltage of 400 V, an energy of 101 mJ, and an ablation time of 3 min.

[0029] The volume of the laser ablation product in step 2 is 4mL, and the volume of the sulfuric acid solution is 0mL, 1mL, 1.3mL, 1.7mL, 2.7mL, 4mL.

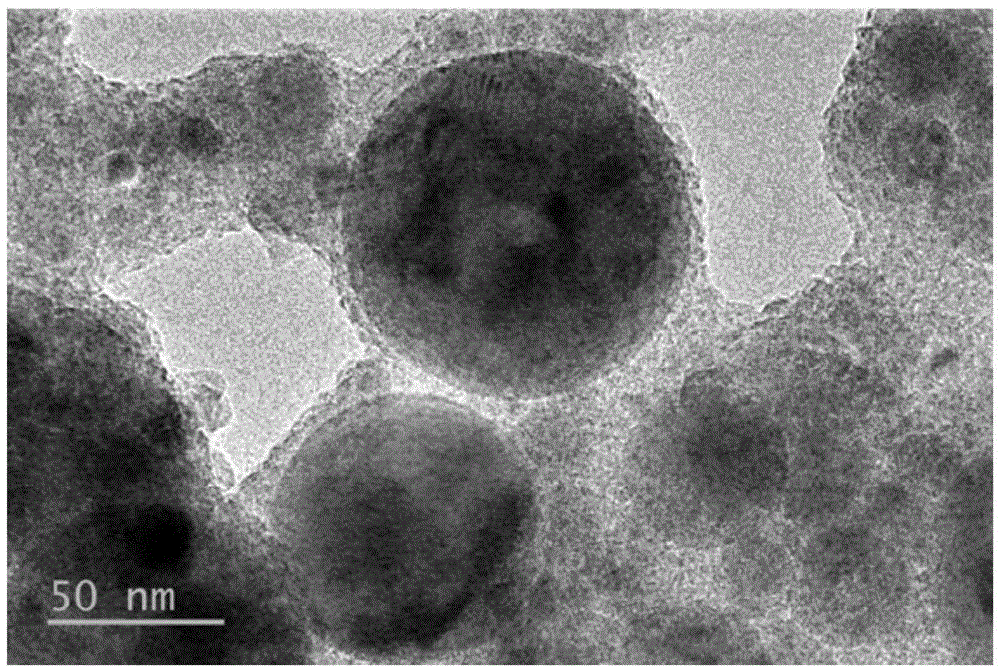

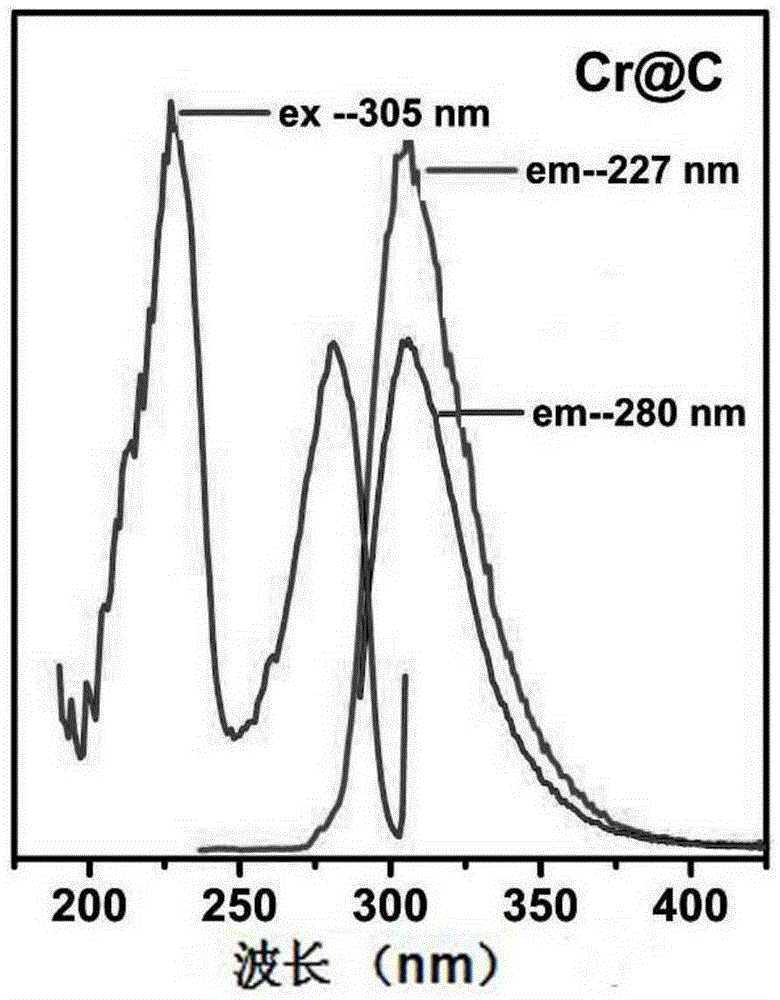

[0030] The obtained CrC core-shell structure nanoparticles were ch...

Embodiment 2

[0032] A method for preparing metal-carbon core-shell nanoparticle, comprising the following steps:

[0033] Step 1. Add the metal target Ti (purity ≥ 99.99%) to the ethanol solution, pass in argon gas, and ablate the metal target with a laser under the stirring condition of 80-90rpm to obtain a laser ablation product;

[0034] Step 2: Add the laser ablation product obtained in Step 1 to a 5v / v% sulfuric acid solution, pass through argon, stir and react at 300rpm at 70°C for 15min, and cool to room temperature to obtain the product.

[0035] The ablation process in step 1 is carried out in a quartz container; the laser emitted by the laser has a wavelength of 1064 nm, a pulse duration of 10 ns, a voltage of 400 V, an energy of 101 mJ, and an ablation time of 3 min.

[0036] The volume of the laser ablation product in step 2 is 4mL, and the volume of the sulfuric acid solution is 0mL, 1mL, 1.3mL, 1.7mL, 2.7mL, 4mL.

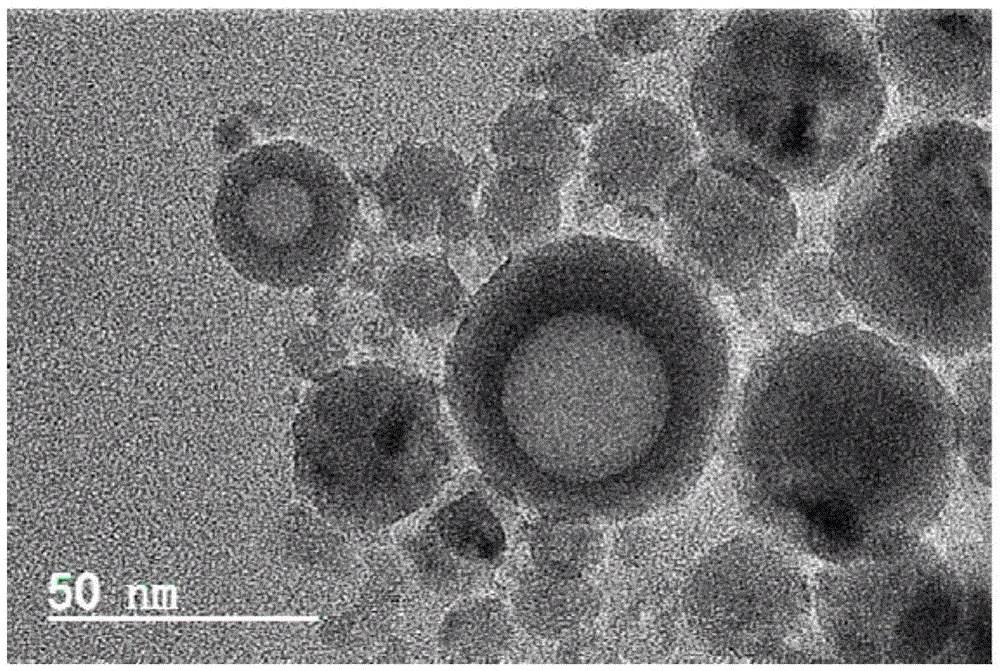

[0037] The samples were characterized by TEM and PL, and the...

Embodiment 3

[0039] A method for preparing metal-carbon core-shell nanoparticle, comprising the following steps:

[0040] Step 1: Add metal target Al (purity ≥ 99.99%) to ethanol solution, pass in argon gas, and use a laser to ablate the metal target under the stirring condition of 80-90rpm to obtain a laser ablation product;

[0041]Step 2: Add the laser ablation product obtained in Step 1 to a 5v / v% sulfuric acid solution, pass through argon, stir and react at 300rpm at 70°C for 15min, and cool to room temperature to obtain the product.

[0042] The ablation process in step 1 is carried out in a quartz container; the laser emitted by the laser has a wavelength of 1064 nm, a pulse duration of 10 ns, a voltage of 400 V, an energy of 101 mJ, and an ablation time of 3 min.

[0043] The volume of the laser ablation product in step 2 is 4mL, and the volume of the sulfuric acid solution is 0mL, 1mL, 1.3mL, 1.7mL, 2.7mL, 4mL.

[0044] The samples were characterized by TEM and PL, and the result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com