Essence microcapsule and preparation method therefor

A technology of flavor microcapsules and flavors, which is applied in the field of flavors, can solve problems such as low flavor coating rate, inability to increase the utilization rate of flavors, and weak wall material oxidation resistance, so as to improve safety performance, reduce health risks, Good embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

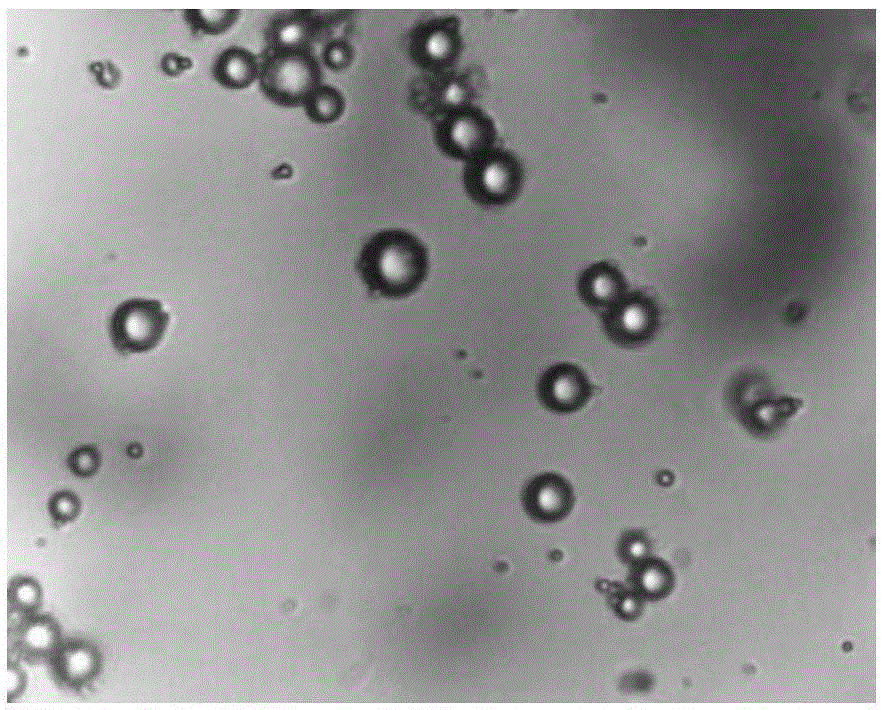

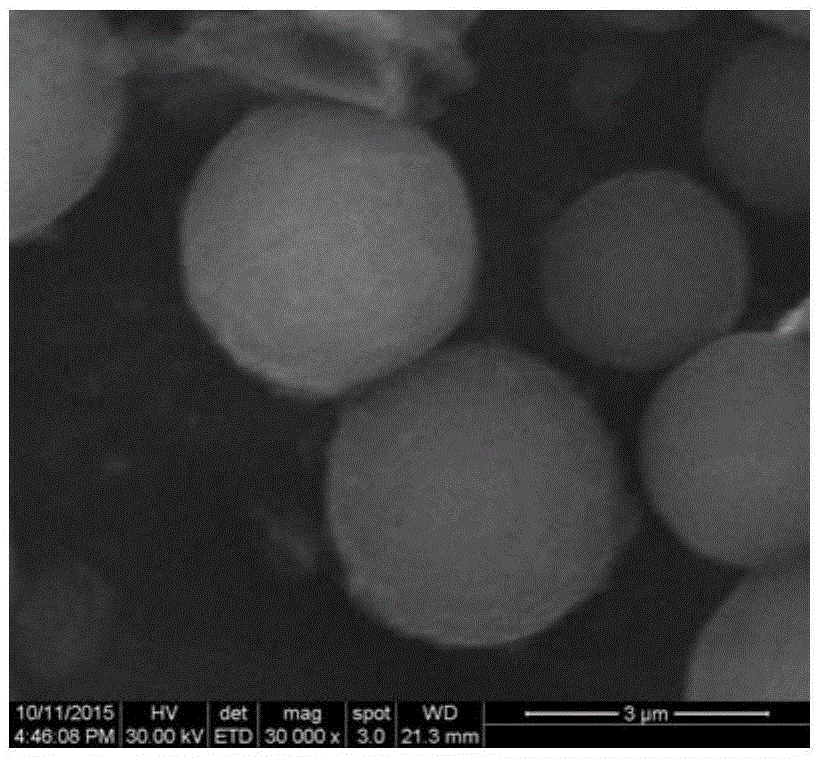

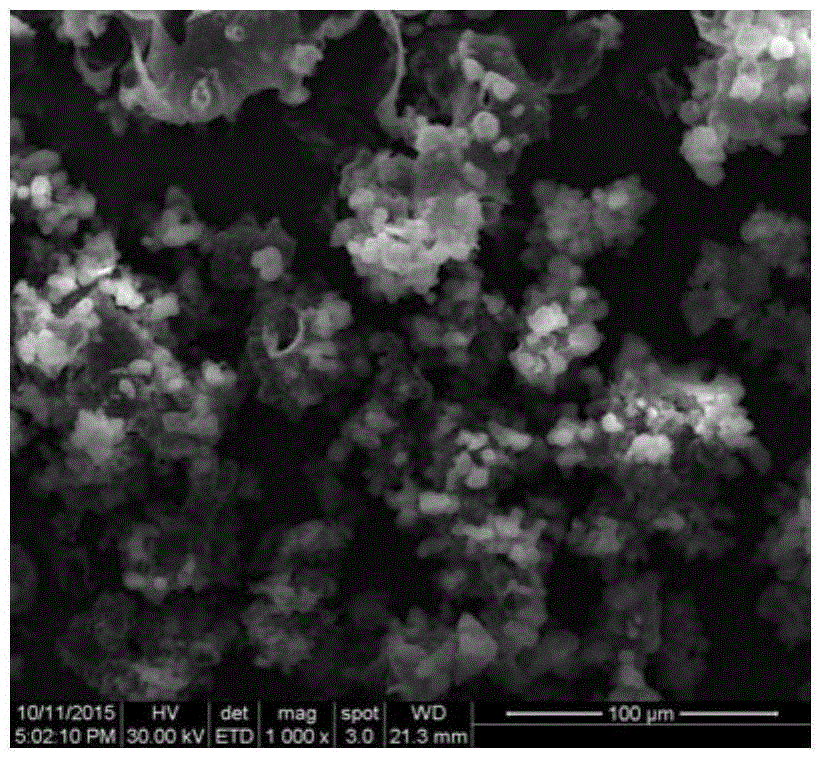

[0029] Next, describe the preparation method of the essence microcapsule according to the second aspect of the present invention, which is used to prepare the essence microcapsule described in the first aspect of the present invention, including the steps: (1) mixing and stirring the capsule core, emulsifier and deionized water evenly The emulsified capsule core is obtained, wherein the material of the capsule core is essence; (2) formaldehyde and melamine are stirred and reacted under heating conditions, then inorganic nanoparticles and polyvinyl alcohol are added, and the stirring is continued to make the polymerization reaction, A prepolymer of the capsule wall is obtained, wherein the capsule wall is a melamine formaldehyde resin filled with inorganic nanoparticles and modified by polyvinyl alcohol; (3) the prepolymer of the capsule wall is added to the emulsified capsule core , adjust the pH value to acidity to react, and then stir, filter, and air dry to complete the prep...

Embodiment 1

[0036] Weigh 3.0883g melamine, 1.8364g formaldehyde aqueous solution (36% by mass), 30ml deionized water, stir for 40min in a constant temperature oil bath at 70°C, and then add 0.0168g nano-TiO 2 Particles (with a particle size of 5 nm to 20 nm), a polyvinyl alcohol (PVA) aqueous solution containing 0.0312 g of PVA, and then continued to stir in a constant temperature oil bath at 70°C for 30 min to obtain an inorganic nanoparticle-filled and polyvinyl alcohol-modified dense Aqueous solution of amine formaldehyde resin prepolymer.

[0037] Weigh 4.7034g of neroli essential oil, 0.0079g of emulsifier SDS, and 30ml of deionized water, and stir vigorously (rotation speed is 1440r / min) for 60min to obtain an emulsified capsule core.

[0038] Add the aqueous solution of the melamine formaldehyde resin prepolymer filled with inorganic nanoparticles and modified by polyvinyl alcohol into the emulsified capsule core, add 3 to 4 drops of n-amyl alcohol to eliminate foam, and then adjus...

Embodiment 2

[0040] Weigh 3.0129g of melamine, 1.8567g of aqueous formaldehyde solution (36% by mass), and 30ml of deionized water, stir for 40min in a constant temperature oil bath at 70°C, and then add 0.0172g of nano-TiO 2Particles (with a particle size of 5nm to 20nm), an aqueous solution of polyvinyl alcohol (PVA) containing 0.0310g PVA, and then continued to stir in a constant temperature oil bath at 70°C for 30min to obtain a dense particle filled with inorganic nanoparticles and modified by polyvinyl alcohol. Aqueous solution of amine formaldehyde resin prepolymer.

[0041] Weigh 4.2 g of sweet-scented osmanthus essential oil, 0.0082 g of emulsifier SDS, and 30 ml of deionized water, and stir vigorously (rotation speed is 1440 r / min) for 60 min to obtain an emulsified capsule core.

[0042] Add the aqueous solution of the melamine formaldehyde resin prepolymer filled with inorganic nanoparticles and modified by polyvinyl alcohol into the emulsified capsule core, add 3 to 4 drops of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com