Method for extracting sardine polypeptide

A technology of sardines and sardine meat, which is applied in fermentation and other directions, can solve safety concerns, kidney toxicity and side effects, and achieve the effects of low cost, wide source of raw materials, and high medicinal economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

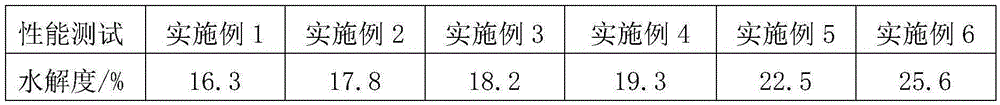

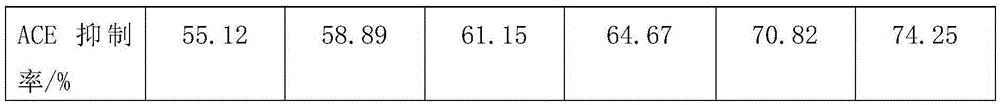

Examples

Embodiment 1

[0024] (1) Clean the sardines, remove their heads and scales, put them into a high-speed tissue masher and stir them into a minced meat shape, and dissolve them in a constant temperature water bath at 37°C for 3 hours;

[0025] (2) Add the minced sardine meat to distilled water at a concentration of 20% (W / V) and stir evenly, add it to the enzymolysis tank, raise the temperature to 45°C, and add the minced sardine meat to the pancreas according to the weight of 2000U / g. Protease, adjust the pH with acid and alkali to keep the pH at 7.5, stir at 1000r / min at a constant speed, heat for 1.5h after enzymatic hydrolysis, then add 3000U / g papain, heat up to 55℃, adjust with acid and alkali to keep the pH at 6.5, 1000r Stir at constant speed / min, keep warm for 2h;

[0026] (3) After the enzymolysis is completed, place the enzymatic hydrolysate in a constant temperature water bath at 95°C for 15 min. After cooling, centrifuge at 5000r / min for 15 min. Take the supernatant and place it in a...

Embodiment 2

[0028] (1) Clean the sardines, remove their heads and scales, put them in a high-speed tissue masher and stir them into a minced meat shape, and dissolve them in a constant temperature water bath at 37°C for 2 hours;

[0029] (2) Add the minced sardine meat to distilled water at a concentration of 25% (W / V) and stir evenly, add it to the enzymolysis tank, raise the temperature to 50℃, and add the minced sardine meat to the pancreas at 2500U / g based on the weight of the minced sardine. Protease, adjust with acid and alkali to keep the pH at 8.0, stir at 2000r / min at a constant speed, after incubating for 2h, add 4000U / g papain, heat to 60℃, adjust with acid and alkali to keep the pH at 7.0, 2000r / Stir at a constant speed for min, keep warm for 2.5h;

[0030] (3) After the enzymolysis is completed, put the enzymatic hydrolysate in a constant temperature water bath at 98°C for 18 min. After cooling, centrifuge at 6000r / min for 18 min. Take the supernatant and place it in a rotary eva...

Embodiment 3

[0032] (1) Clean the sardines, remove their heads and scales, put them in a high-speed tissue mixer and stir them into a minced meat shape, and dissolve them in a constant temperature water bath at 37°C for 2.5 hours;

[0033] (2) Add the minced sardine meat to distilled water at a concentration of 30% (W / V) and stir it evenly, add it to the enzymolysis tank, raise the temperature to 55℃, and add 3000U / g to the pancreas based on the weight of the minced sardine meat. Protease, adjust with acid and alkali to keep the pH at 8.5, stir at 3000r / min at a constant speed, incubate for 2.5h after enzymatic hydrolysis, then add 2500U / g of papain, heat up to 65℃, adjust with acid and alkali to keep the pH at 7.3, 3000r Stir at a constant speed / min, heat preservation and enzymatic hydrolysis for 2h;

[0034] (3) After the enzymolysis is completed, place the enzymatic hydrolysis solution in a constant temperature water bath at 98°C for 20 min. After cooling, centrifuge at 7000r / min for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com