Energy management internet managed waste heat driven power generation, heating, cooling, vapor generation, water generation, material manufacturing and sewage treatment cogeneration system

A technology of electric heating, cooling and waste heat, which is applied in heat pumps, refrigerators, energy industries, etc., and can solve the problems of low utilization rate of heat recovery equipment, corrosion of heating medium, and low quality of waste heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

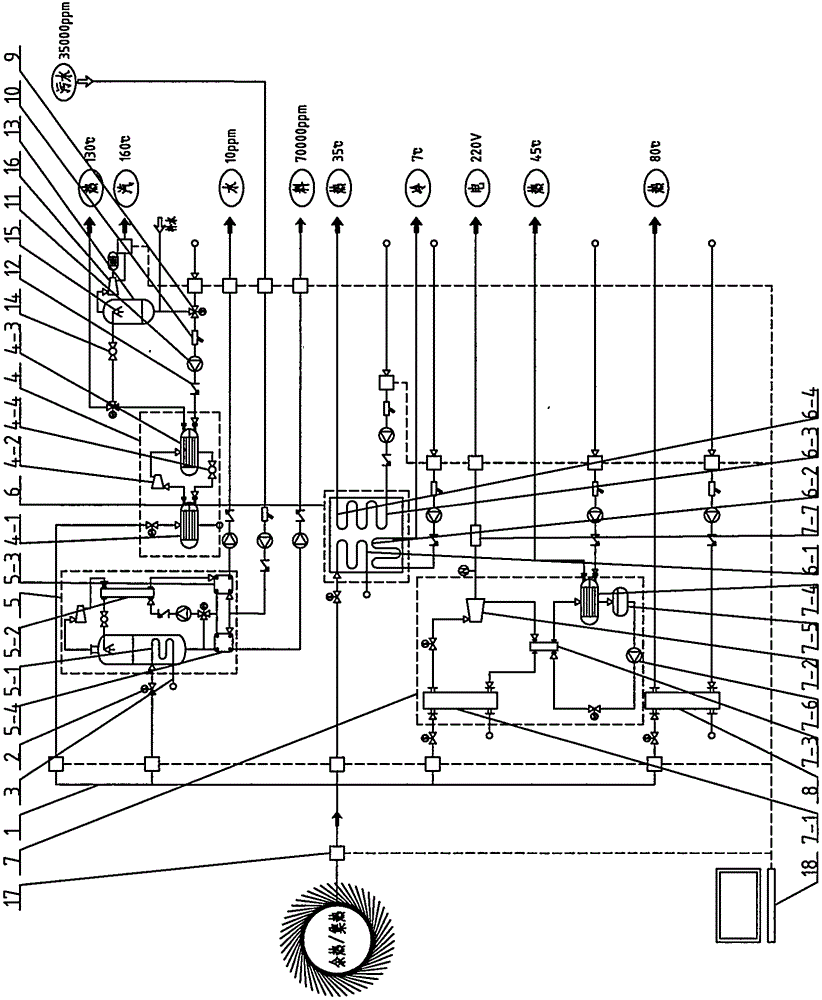

[0071] Attached figure 1 As shown, the description is as follows: it consists of five sets of seamless steel waste heat pipes 1 with a diameter of 150mm and a wall thickness of 2.5mm, a sensor data acquisition and exchange module 17, a seamless steel tee with a diameter of 150mm and a wall thickness of 2.5mm, a diameter of 150mm, A seamless steel two-way valve 2 with a wall thickness of 2.5mm, a seamless steel return pipe 3 with a diameter of 150mm and a wall thickness of 2.5mm, and a water source heat pump unit with a heating capacity of 650kW or a steam production capacity of 1t / h connected in parallel 4, 15t / d Water volume + 15t / d raw material production + 30t / d sewage treatment volume 5, 400kW cooling capacity + 900kW heating capacity absorption unit 6, 100kW power generation + 1150kW heating capacity Organic Rankine cycle unit 7 , 500kW heat exchanger 8, forming an integrated system that jointly provides seven functions of power generation, heating, cooling, steam product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com