Waterborne binder positive electrode material for lithium iron phosphate battery and preparation method therefor

A technology of lithium iron phosphate battery and water-based binder, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of high toxicity at the production site, affecting the migration rate of electrons and protons, and high recycling costs, and achieves green and non-toxic Pollution production process, good chemical stability, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

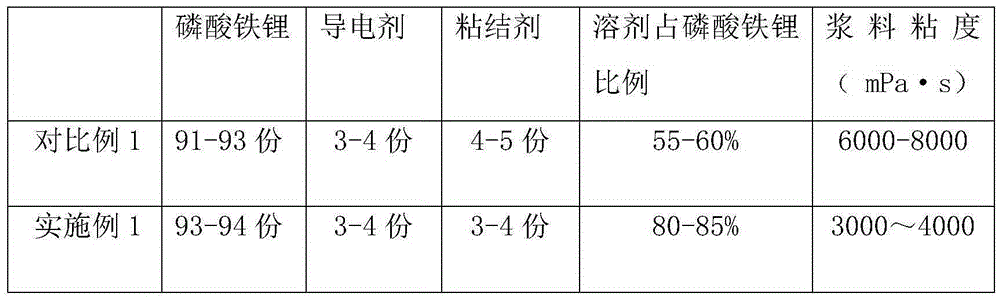

Embodiment 1

[0031] (1) First dry the lithium iron phosphate, conductive agent, binder and additive respectively, and then weigh: lithium iron phosphate: 93 parts, conductive agent: 3 parts, binder: 4 parts, additive: 6 parts, Deionized water: 74.4 parts;

[0032] (2) The binding agent (carboxymethyl chitosan and polyethylene glycol is 2.8:1 by weight), additive trihydroxypropane-triacrylate, and 80% of deionized water are added together to the double planetary mixer Stir in the inner barrel of the double-layer mixing barrel for 2 hours, and at the same time add 50°C hot water to the outer compartment of the double-layer mixing barrel for circulation, so that the binder and additives can be quickly dispersed and dissolved; the dispersion of the double planetary mixer The speed is 600±20 m / s, the revolution is 20±1 m / s;

[0033] (3) Add conductive agent acetylene black and carbon black (SP) to the mixed material in (2), and stir for 1 to 2 hours with a double planetary mixer at a dispersio...

Embodiment 2

[0039] (1) First dry the lithium iron phosphate, conductive agent, binder and additive respectively, and then weigh: lithium iron phosphate: 94 parts, conductive agent: 4 parts, binder: 3 parts, additive: 3 parts, Deionized water: 79.9 parts;

[0040] (2) The binding agent (carboxymethyl chitosan and polyethylene glycol is 3.3:1 by weight), additive trihydroxypropane-triacrylate, and 80% of deionized water are added together to the double planetary mixer Stir in the inner barrel of the double-layer mixing barrel for 3 hours, and at the same time add hot water at 55°C to the outer compartment of the double-layer mixing barrel for circulation, so that the binder and additives can be quickly dispersed and dissolved; the dispersion of the double planetary mixer The speed is 600±20 m / s, the revolution is 20±1 m / s;

[0041] (3) Add conductive agent Ketjen black and carbon nanotubes to the mixed material in (2), and the double planetary mixer is 1500 ± 20 m / s with a dispersion speed...

Embodiment 3

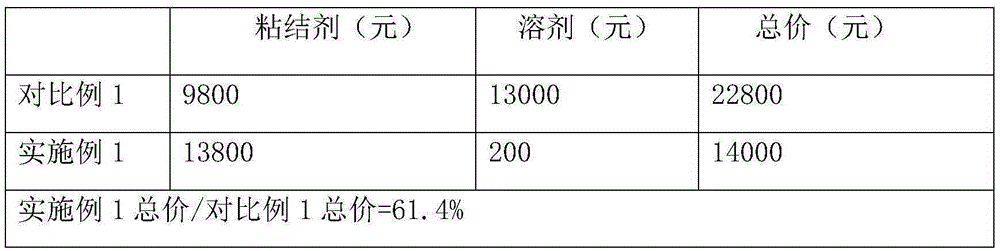

[0054] Embodiment 3: Performance test of lithium iron phosphate battery

[0055] The positive electrode materials prepared in Example 1 and Comparative Example 1 were respectively made into 5 groups of lithium iron phosphate batteries, wherein the positive electrode materials in Example 1 were used to make W1, W2, W3, W4, W5 this group of lithium iron phosphate batteries. The positive electrode materials in Comparative Example 1 were made into five groups of lithium iron phosphate batteries D1, D2, D3, D4, and D5, and their basic properties are shown in Table 3 below:

[0056] Table 3: Basic performance indicators of the battery:

[0057]

[0058] As can be seen from the above table 3, the average value of the 1C discharge platform voltage of the lithium iron phosphate battery made of the positive electrode material of the present invention is 0.0346V higher than that of the lithium iron phosphate battery made of the oil-based material, and the average value of the internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com