A fixing device for deep hole drilling and welding blades

A fixing device, deep hole drilling technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of blade falling off or slipping, low welding quality, high rejection rate, and achieve convenient welding, high welding precision, The effect of high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

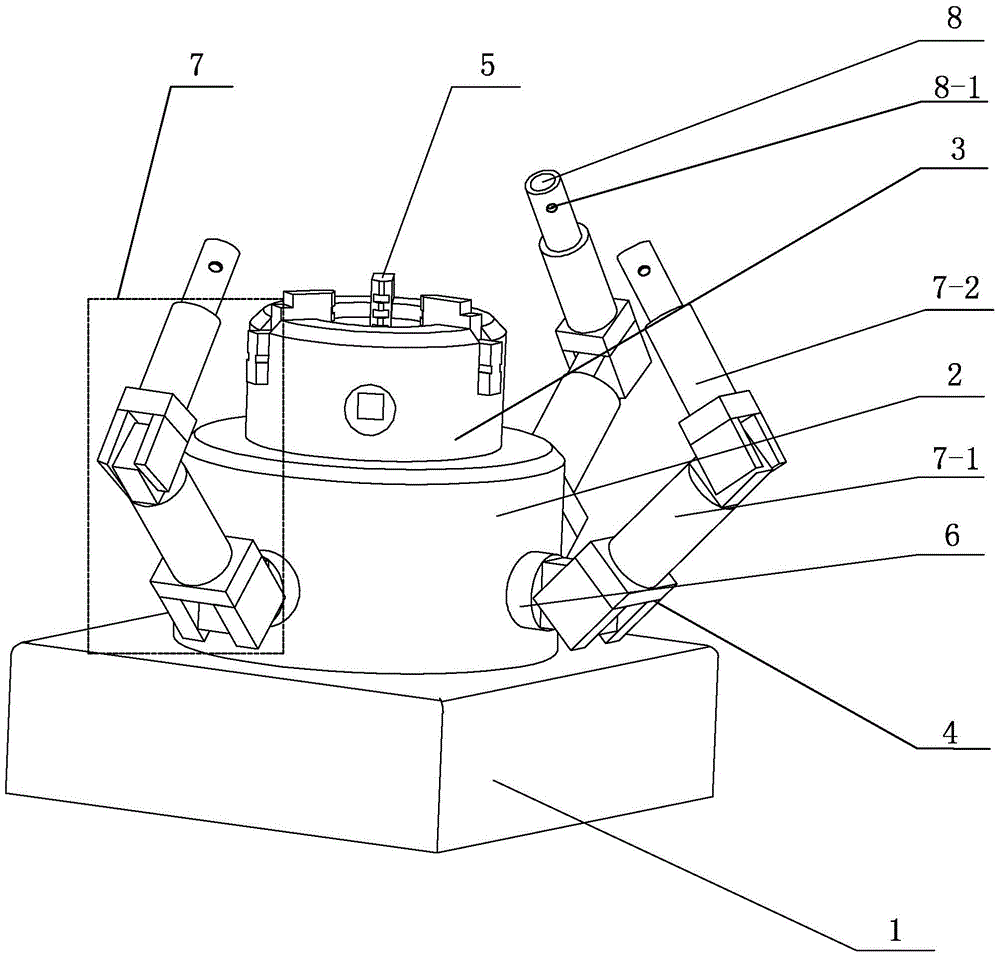

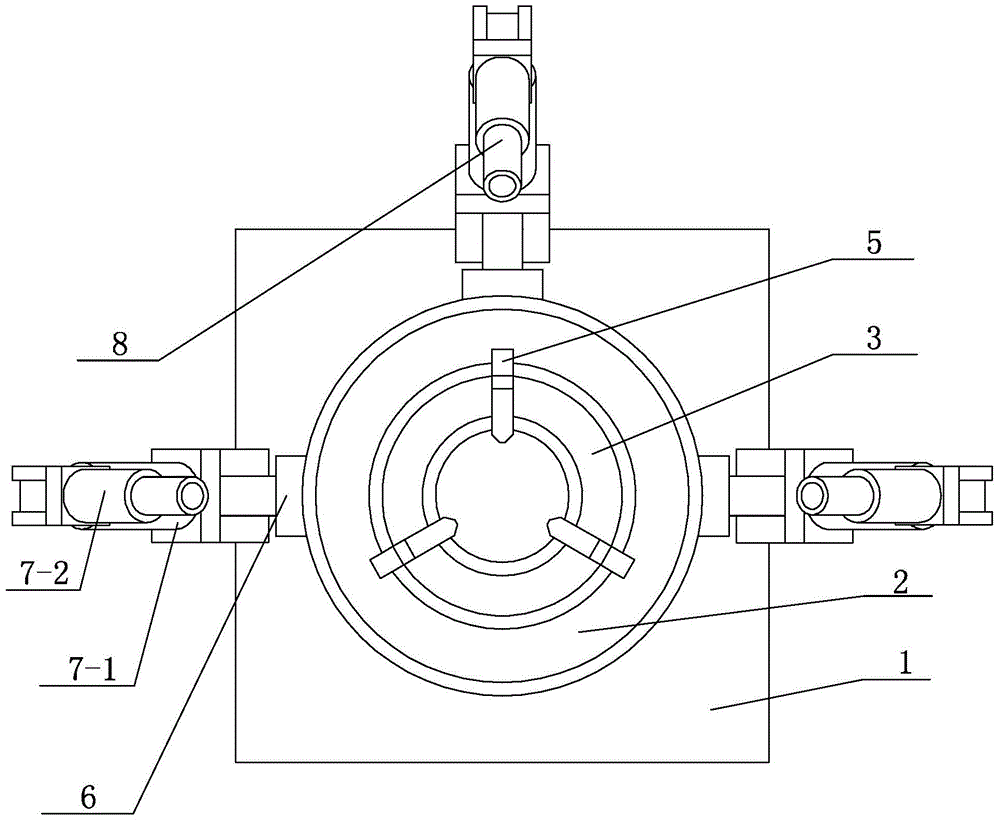

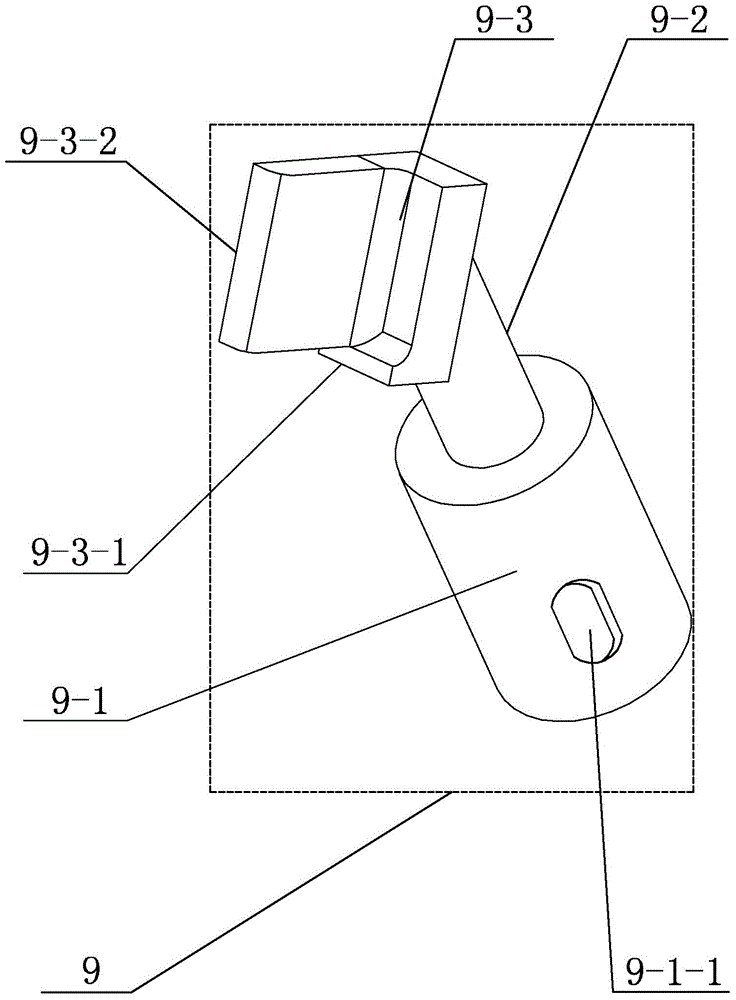

[0030] Specific implementation mode one: combine Figure 1 to Figure 17 This embodiment is described. A fixing device for deep hole drilling and welding blades described in this embodiment includes a base 1, a hydraulic lifting platform 2, a chuck body 3, a first fixing device 9, a second fixing device 10, and a third fixing device 11. Three grippers 4 and multiple claws 5, the hydraulic lifting platform 2 is set in the middle of the upper surface of the base 1, the chuck body 3 is set in the middle of the upper surface of the hydraulic lifting platform 2, and the upper end surface of the chuck body 3 is along the Its circumferential direction is evenly provided with a plurality of claws 5, and the deep hole drill 12 is fixed by a plurality of claws 5, and the upper end surface of the deep hole drill 12 is provided with a center blade 13, an outer blade 14, a first guide block 15, an inner Blade 16 and second guide block 17, each gripper 4 comprises fixed part 6, hydraulic dev...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, each hydraulic device 7 described in this embodiment includes an intermediate shaft 7-1 and a hydraulic shaft 7-2, one end of the intermediate shaft 7-1 is hinged to the fixed part 6, and the other end of the intermediate shaft 7-1 is connected to the One end of the hydraulic shaft 7-2 is hinged, and the other end of the hydraulic shaft 7-2 is provided with a sleeve 8 . In this way, when each clamping hand is fixed with the blade and the guide block, each boss is in a vertical direction, such as Figure 5 , Figure 9 and Figure 13In this state, the hydraulic shaft 7-2 can be stretched, so that each clamping hand can be clamped with the corresponding center blade 13, outer blade 14, first guide block 15, inner blade 16 and second guide block 17. Tight fix. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: combination figure 1 Referring to this embodiment, the outer wall of each sleeve 8 in this embodiment is provided with a through hole 8 - 1 along the radial direction of the sleeve 8 , and each sleeve 8 is provided with a spring. Arranged in this way, the spring is used to adjust the depth of the first installation part 9-1, the second installation part 10-1 and the third installation part 11-1 in the respective sleeves 8, so as to ensure that the guide block and the blade are clamped. The clamping force generated when tightening and fixing is uniform, and the phenomenon of uneven clamping force is avoided. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com