Method for preparing DMAPPA (N-(3-dimethyl aminopropyl) acrylamide) through catalytic amidation

A dimethylaminopropyl, catalytic amide technology, applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of reduced catalytic activity, low flash point temperature, potential safety hazards, etc. Good quality, good selectivity, convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

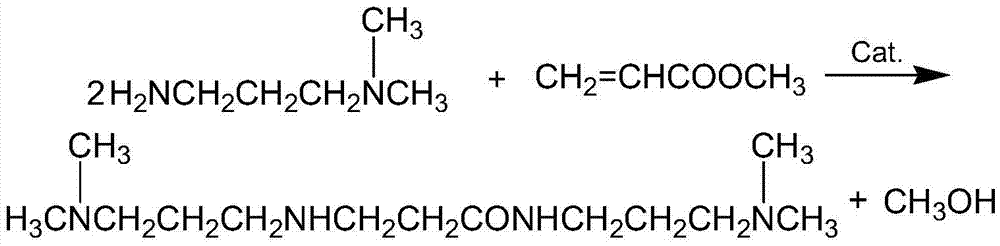

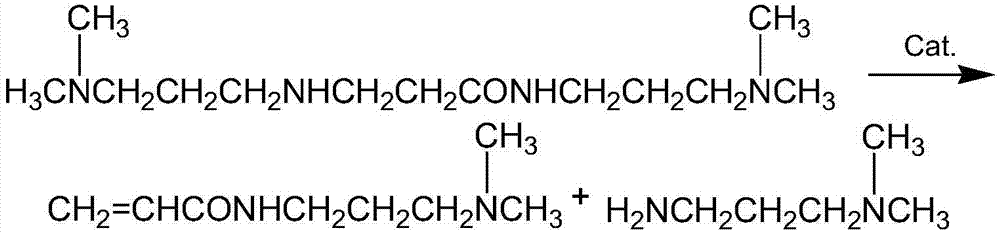

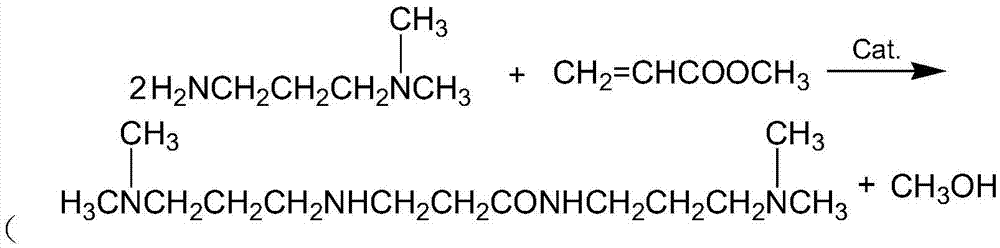

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 173.7kg of methyl acrylate, 517.2kg of N,N-dimethyl-1,3-propylenediamine, 13.8kg of dibutyltin oxide and 0.69kg of hydroquinone into the reactor, stir and heat up to 150 ℃ for 12 hours, then lower the temperature to 120 ℃, and distill off excess N,N-dimethyl-1,3-propanediamine and methanol under reduced pressure at 10mmHg, and the remaining material in the kettle is the intermediate product N-diamine Methylaminopropyl-β-dipropylaminoacrylamide. Excess N,N-dimethyl-1,3-propanediamine and methanol are separated through a distillation tower, and the recovered raw material N,N-dimethyl-1,3-propanediamine is put back into the reaction.

[0033] (2) Transfer 494kg of the above-mentioned intermediate product into a distillation reactor, reduce the pressure to 5mmHg, stir and heat up to 230°C, and carry out distillation treatment on the intermediate product. The distillate contains the raw material N,N-dimethyl-1,3 -Propylenediamine and the product N-(3-dimethylaminopr...

Embodiment 2

[0036] (1) Add 173.7kg of methyl acrylate, 413.7kg of N,N-dimethyl-1,3-propylenediamine, 5.87kg of dibutyltin dilaurate and 1.17kg of p-hydroxyanisole into the reactor, and stir Raise the temperature to 170°C and keep it for 10 hours, then lower the temperature to 140°C, distill off excess N,N-dimethyl-1,3-propanediamine and methanol under reduced pressure at 17mmHg, the remaining material in the kettle is the intermediate product N-Dimethylaminopropyl-β-dipropylaminoacrylamide. Excess N,N-dimethyl-1,3-propanediamine and methanol are separated through a distillation tower, and the recovered raw material N,N-dimethyl-1,3-propanediamine is put back into the reaction.

[0037] (2) Transfer 487.9kg of the above-mentioned intermediate product into a distillation reactor, reduce the pressure to 12mmHg, stir and heat up to 260°C, and carry out distillation treatment on the intermediate product. The distillate contains the raw material N,N-dimethyl-1, 3-propanediamine and the product...

Embodiment 3

[0040] (1) 173.7kg methyl acrylate, 342.9kg N,N-dimethyl-1,3-propylenediamine, recovered 174.3kgN,N-dimethyl-1,3-propylenediamine, recovered 10.1kg Dibutyltin oxide and add 3.7kg of new dibutyltin oxide, and 1.73kg of p-tert-butylphenol into the reaction kettle, stir and heat up to 190°C for 8 hours, then cool down to 160°C, under 25mmHg Excessive N,N-dimethyl-1,3-propanediamine and methanol are evaporated under reduced pressure, and the remaining material in the kettle is the intermediate product N-dimethylaminopropyl-β-dipropylaminoacrylamide. Excess N,N-dimethyl-1,3-propanediamine and methanol are separated through a distillation tower, and the recovered raw material N,N-dimethyl-1,3-propanediamine is put back into the reaction.

[0041] (2) Transfer 497.5kg of the above-mentioned intermediate product into a distillation reactor, reduce the pressure to 15mmHg, stir and heat up to 280°C, and carry out distillation treatment on the intermediate product. The distillate contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com