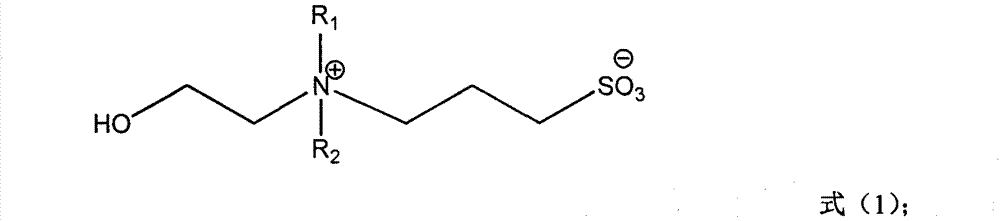

Ethoxyl inner salt based eutectic substance

A hydroxyethyl and eutectic technology, which is applied in the field of eutectic material preparation, can solve problems such as corrosion, poor catalyst stability, and easy deliquescence, and achieve the effects of heat resistance, convenient post-processing, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

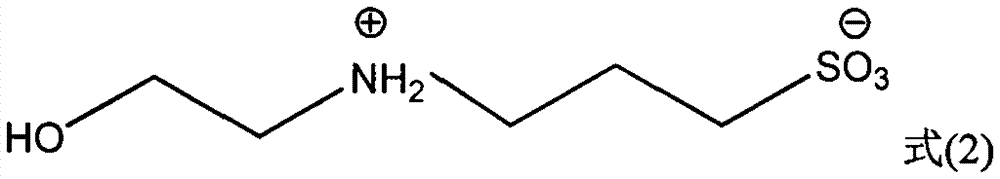

[0024] In a 50mL beaker, add 18.322 grams (0.1mol) of internal salt of the formula (2) and 18.418 grams (0.2mol) of glycerol, stir and react at 120°C for 0.5 hour, then place the beaker in a vacuum oven, The temperature is 0.1MPa, the temperature is 60°C, and the negative pressure is dried for 12 hours to obtain a transparent colorless liquid with a yield close to 100%.

[0025]

[0026] The prepared eutectic substance is liquid at normal temperature and pressure. Combined with an acidic catalyst, it can be used as a dissolution medium for natural straw cellulose; mixed with sodium hydroxide, it can be used as an excellent catalytic system for transesterification of biodiesel.

Embodiment 2

[0028] In a 50mL beaker, add 18.322 grams (0.1mol) of the internal salt of the formula (2) and 36.836 grams (0.4mol) of glycerin, and stir the reaction at 60°C for 3 hours to complete the reaction. The vacuum degree is 1.0MPa and the temperature is 60°C , dried under negative pressure for 2 hours to obtain a transparent colorless liquid with a yield of 100%. The prepared eutectic substance is liquid at normal temperature and pressure.

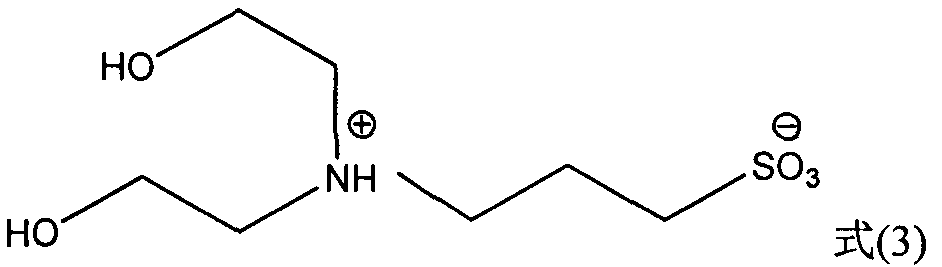

Embodiment 3

[0030] In a 50mL beaker, add 22.728 grams (0.1mol) of the internal salt of the formula (3) and 9.209 grams (0.1mol) of glycerol, stir and react at 90°C for 2.5 hours, then place the beaker in a vacuum oven, The temperature is 0.5MPa, the temperature is 70°C, and the negative pressure is dried for 5 hours to obtain a transparent colorless liquid with a yield close to 100%. The prepared eutectic substance is liquid at normal temperature and pressure.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com