Catalyst component used for olefin polymerization and preparation method thereof and catalyst used for olefin polymerization and application

A technology of olefin polymerization and catalyst, which is applied in the application field of catalyst in olefin polymerization reaction, and can solve problems such as unstable preparation process, poor carrier molding effect, and difficult control of carrier shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] According to a preferred embodiment of the present invention, the average particle diameter of the magnesium-containing carrier is 10-100 microns, and the particle size distribution is less than 1.2; preferably, the average particle diameter of the magnesium-containing carrier is 40-60 microns, the particle size distribution is less than 1.2; The diameter distribution is 0..6-1.1. In this preferred embodiment, the catalyst prepared from the magnesium-containing support is capable of higher hydrogen modulation sensitivity and yields olefin polymers with lower bulk density. In the present invention, the average particle diameter and particle size distribution of the magnesium-containing carrier can be measured by using a MasterSizer 2000 laser particle size analyzer (manufactured by Malvern Instruments Ltd).

[0057] According to the present invention, the magnesium-containing carrier is prepared by the following method, which includes: in the presence of a third inert me...

preparation example 1

[0120] This preparation example is used to illustrate the magnesium-containing carrier provided by the present invention and its preparation method.

[0121] (1) magnesium chloride alcoholate solid is prepared according to the disclosed method of embodiment 1 in CN1718595A, specifically as follows:

[0122] In a 150L reactor with a stirring device, 10kg (105mol) of magnesium chloride and 12.6kg of ethanol (273mol) were added into 60L of white oil with a viscosity of 30 centipoise (20°C) and reacted at 125°C for 2 hours. Then transfer the mixture of molten adduct and white oil to the medium of methyl silicone oil that has been preheated to 125°C. The viscosity of the methyl silicone oil is 300 centipoise (20°C), and the amount of methyl silicone oil is 120L ; Stir at a speed of 200 rpm for 10-30 minutes to obtain a mixed solution. Introduce the mixed solution into a high-gravity rotating bed for dispersion, and introduce the dispersed mixed solution into a hexane medium that h...

preparation example 2

[0126] This preparation example is used to illustrate the magnesium-containing carrier provided by the present invention and its preparation method.

[0127] According to the step (1) in the preparation example 1, the magnesium chloride alcoholate solid A2 was prepared.

[0128] In a 0.6L reactor, add 200mL of hexane, 60g (0.279mol) of magnesium chloride alcoholate solid A2, 3.9mL (0.05mol) of epichlorohydrin, react at 10°C for 6 hours, and press filter. The resulting press-filtered product was washed 5 times with hexane. Finally, the product was vacuum-dried at 50° C. for 2 hours to obtain the magnesium-containing carrier Z2.

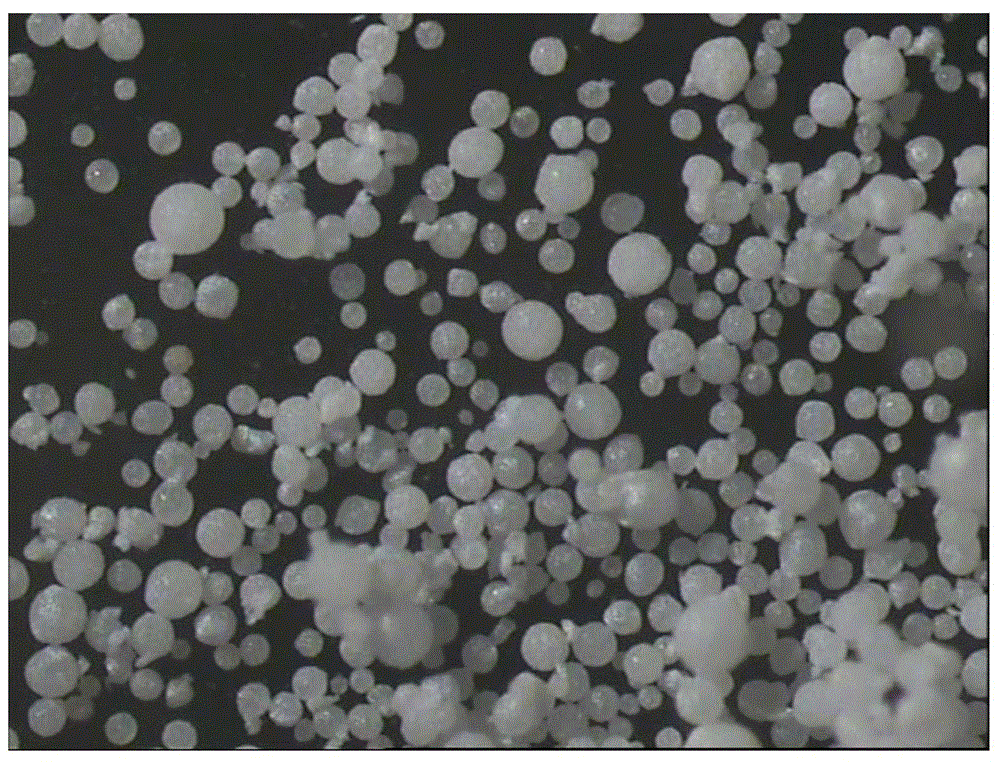

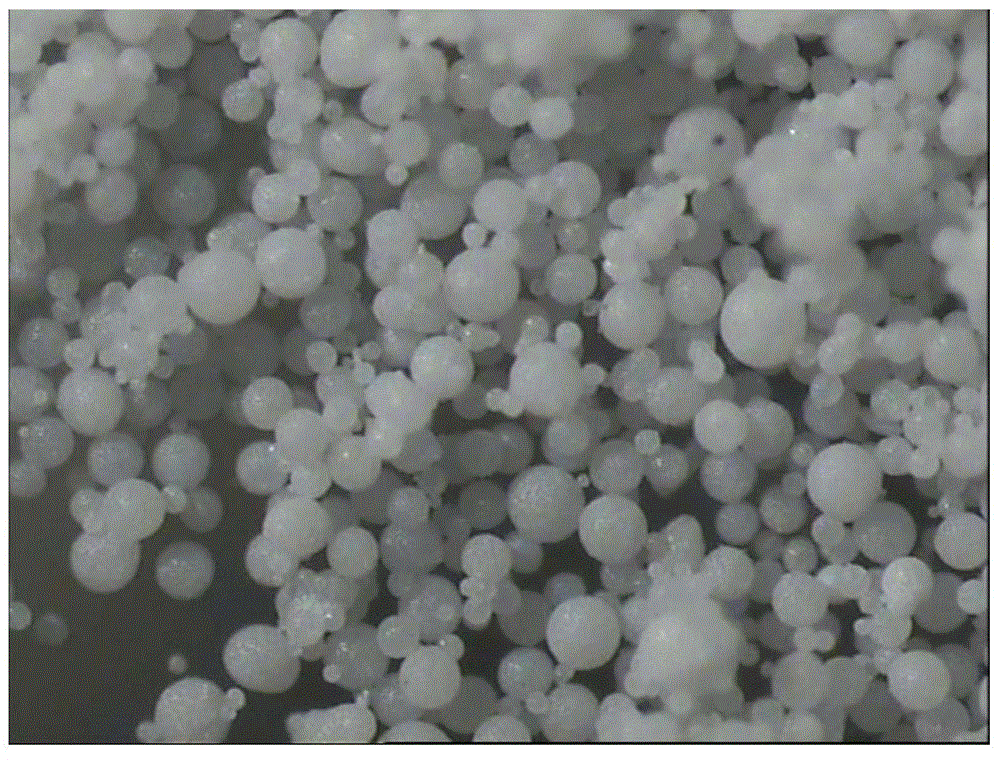

[0129] The average particle diameter (D50) of the magnesium-containing carrier Z2 is 52 microns, and the particle size distribution ((D90-D10) / D50) is 0.8. The particle morphology observed by optical microscope is as follows: figure 2 shown. It can be seen from the figure that the particle shape of the olefin polymerization catalyst carrier Z2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com