Preparation method of quick-dry scratch-resistant water-borne wood coating

A wood coating, water-based technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of unable to realize the adjustment and selection of whisker size and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

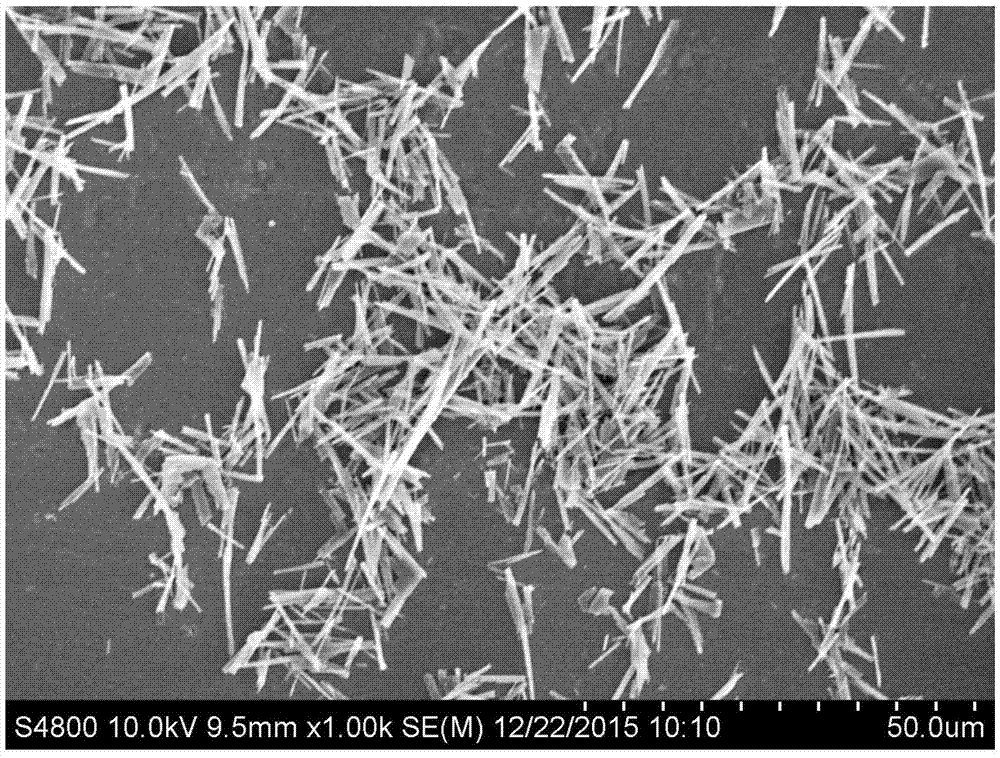

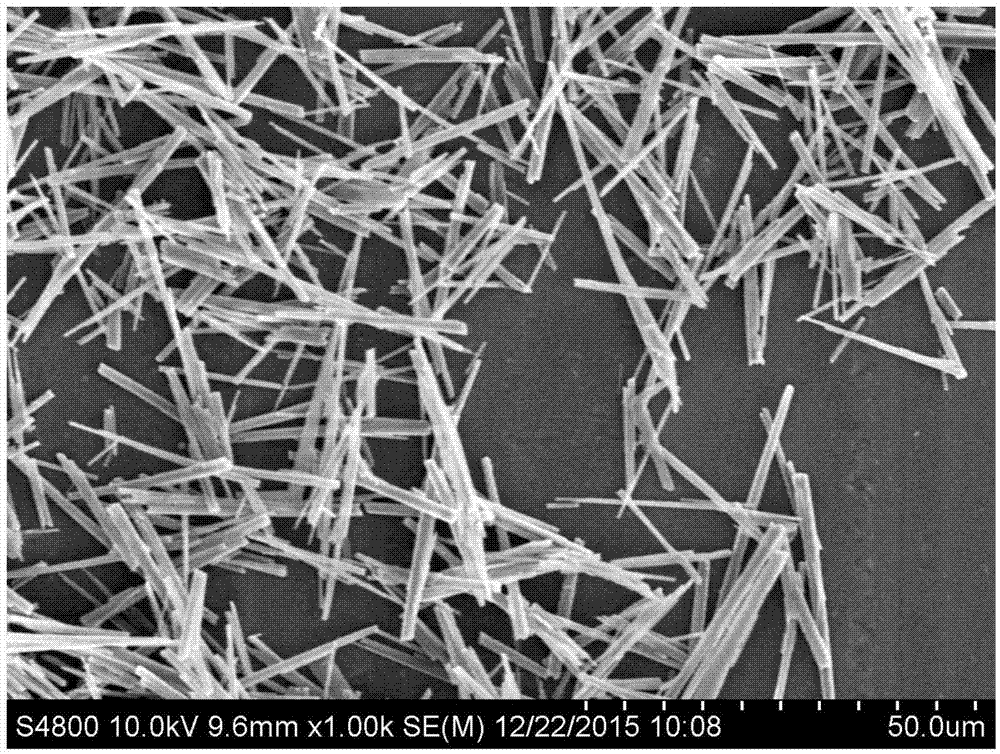

Image

Examples

Embodiment 1

[0031] Add 1000kg water, 50kg calcium chloride and 5kg CTAB into a 2000L hydrothermal reaction kettle in batches, stir to dissolve, add 10kg ammonium sulfate, stir evenly, gradually raise the temperature to 100℃, set the speed to 20rpm, and stop after 30min of hydrothermal reaction Heat the reaction. After natural cooling, put the material in the centrifuge, centrifuge at 10000rpm at -5℃ for 20min, slowly pour the supernatant into a clean centrifuge bucket, centrifuge again at 10000rpm at -5℃ for 20min, repeat this operation twice to obtain The supernatant containing the whisker micronuclei is used as the mother liquor for the subsequent reaction.

[0032] Take 10kg of the small-size solid whisker washed by centrifugation, add it to 125kg of water-based polyurethane dispersion with 40% solid content by wet-on-wet, stir and disperse, add 310g defoamer (TEGO825), defoamer (TEGO902) 155g, dispersing agent (TEGO740w) 125g, wetting agent (TEGO245) 420g, stirring and dispersing unifor...

Embodiment 2

[0036] Add 1500kg water, 50kg calcium chloride and 7.5kg CTAB into a 2000L hydrothermal reaction kettle in batches, stir to dissolve, add 15kg ammonium sulfate, stir evenly, gradually increase the temperature to 150℃, set the rotation speed to 900rpm, hydrothermally react for 60min Stop the heating reaction. After natural cooling, put the material in the centrifuge, centrifuge at 11000rpm at -5°C for 40min, slowly pour the supernatant into a clean centrifuge bucket, centrifuge again at 11000rpm at -5°C for 40min at high speed, repeat this operation twice, get rich The supernatant containing the whisker micronuclei is used as the mother liquor for the subsequent reaction.

[0037] Take 10kg of the small-size solid whisker washed by centrifugation, add it to 150kg of water-based polyurethane dispersion with 45% solid content by wet-on-wet method, stir and disperse, add 330g defoamer (TEGO825), defoamer (TEGO902) 165g, dispersant (TEGO740w) 129g, wetting agent (TEGO245) 427g, stir ...

Embodiment 3

[0041] Add 1350kg water, 50kg calcium chloride and 6kg CTAB into a 2000L hydrothermal reaction kettle in batches, stir to dissolve, add 11kg ammonium sulfate, stir evenly, gradually heat up to 130℃, set the speed to 200rpm, and stop the hydrothermal reaction after 45min Heat the reaction. After natural cooling, put the material into the centrifuge, centrifuge at 12000rpm at -5℃ for 30min, slowly pour the supernatant into a clean centrifuge bucket, centrifuge again at 12000rpm at -5℃ for 30min at high speed, repeat this operation twice to obtain The supernatant containing the whisker micronuclei is used as the mother liquor for the subsequent reaction.

[0042] Take 10kg of the small-sized solid whisker washed by centrifugation, add it to 140kg of water-based polyurethane dispersion with 42% solid content by wet-on-wet method, stir and disperse, add 326g defoamer (TEGO825), defoamer (TEGO902) 161g, dispersant (TEGO740w) 122g, wetting agent (TEGO245) 421g, stir and disperse unifor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com