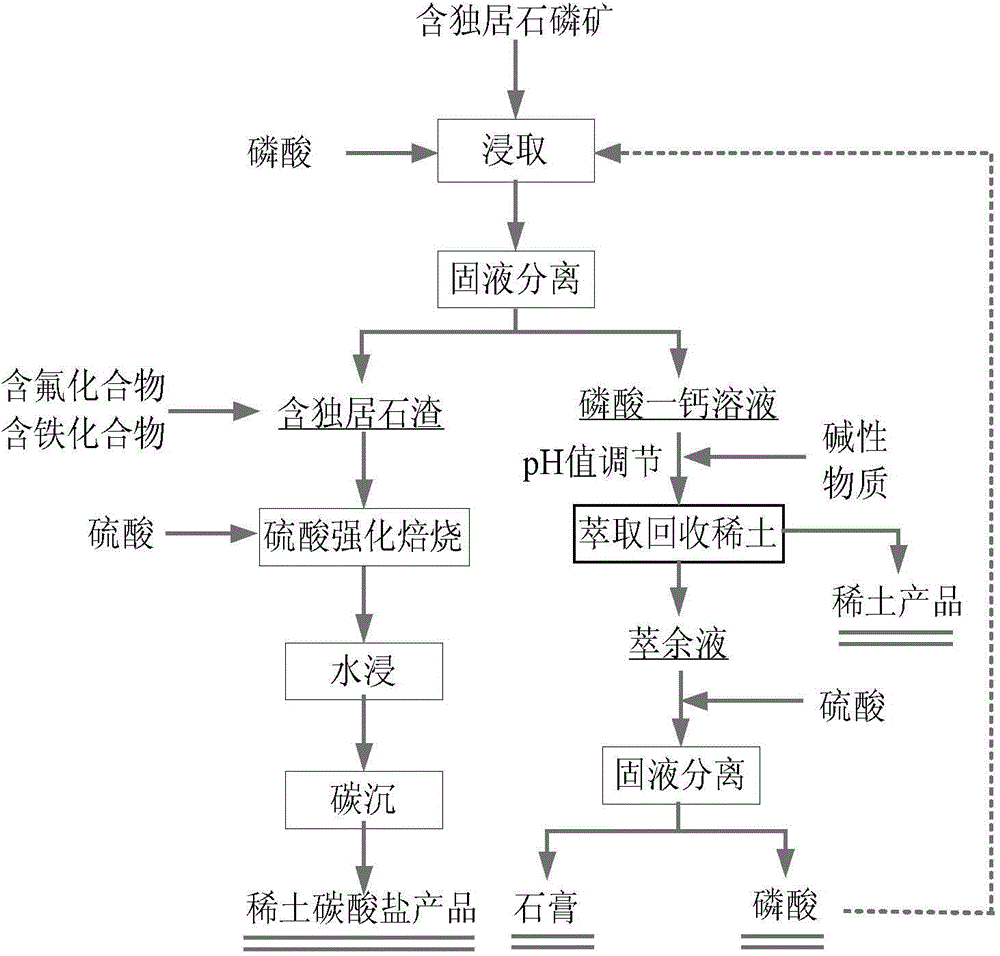

Method for comprehensive recovery of phosphor and rare earth from monazite-containing phosphate rock

A rare earth and stone phosphorus technology, which is applied in the preparation of phosphorus and the improvement of process efficiency, can solve the problems of difficult mosaic dissociation, failure to achieve effective recycling, and inability to completely decompose monazite, so as to improve the recovery rate of rare earth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) With 500g of phosphate rock containing 23.6% of monazite (containing 60% of rare earth) and 15.5% of total rare earth content as raw material, it is leached with phosphoric acid solution whose mass concentration is 15% (calculated as P2O5), and the liquid-solid ratio of the control system 2L: 1kg, add 100mL of phosphoric acid solution, react at 25°C for 8 hours, obtain a rare earth-containing monocalcium phosphate solution and monazite slag after filtration, obtain 124mL rare earth-containing monocalcium phosphate solution and 12g monazite slag , the total weight of the obtained monazite-containing slag accounts for 36.3% of the weight of the phosphate rock raw material.

[0054] (2) Take the obtained monocalcium phosphate solution as raw material, add sodium carbonate therein, adjust the pH value of the system to be 0.1, after adjusting the pH value, the calcium ion content in the formed dicalcium phosphate in the system accounts for the total calcium ion content in...

Embodiment 2

[0060] (1) With 500g of phosphate rock containing 10% of monazite (55% rare earth) and a total rare earth content of 6.2% as raw material, it is leached with a phosphoric acid solution whose mass concentration is 18% (calculated as P2O5), and the liquid-solid ratio of the control system 4L: 1kg, react at 105°C for 18 hours, filter to obtain a rare earth-containing monocalcium phosphate solution and monazite-containing slag, and obtain a rare-earth-containing monocalcium phosphate solution and monazite-containing slag The total weight accounts for 15.2% of the weight of the phosphate rock raw material.

[0061] (2) Take the obtained monocalcium phosphate solution as raw material, add sodium carbonate therein, adjust the pH value of the system to be 0.1, after adjusting the pH value, the calcium ion content in the formed dicalcium phosphate in the system accounts for the total calcium ion content in the system 2.2% of the content. Then add extractant organic solution (extractan...

Embodiment 3

[0066] (1) Use phosphate rock containing 5.8% of monazite and 3.9% of rare earth as raw material, use phosphoric acid solution with a mass concentration of 35% (calculated as P2O5) for leaching, control the liquid-solid ratio of the system at 10L: 1kg, and react at 110°C for 1h After filtering, the monocalcium phosphate solution containing rare earth and monazite slag are obtained, and the monocalcium phosphate solution containing rare earth and monazite slag are obtained after filtration. .

[0067] (2) Take the obtained monocalcium phosphate solution as raw material, add sodium hydroxide therein, and adjust the pH value of the system to be 0.15. 2.1% of the total content. Then add extractant organic solution (extractant P204, organic solvent is sulfonated kerosene, extractant concentration is 0.5mol / L) in monocalcium phosphate solution, this extractant organic solution is 5:1 compared with monocalcium phosphate solution , extracting and recovering the rare earth in the mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com