Thiophilic adsorption chromatography monolithic material as well as preparation method and application thereof

A monolithic material and chromatographic technology, applied in the field of thiophilic chromatographic monolithic materials and their preparation, can solve the problems of loss of functionalized groups, inability to reuse multiple times, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

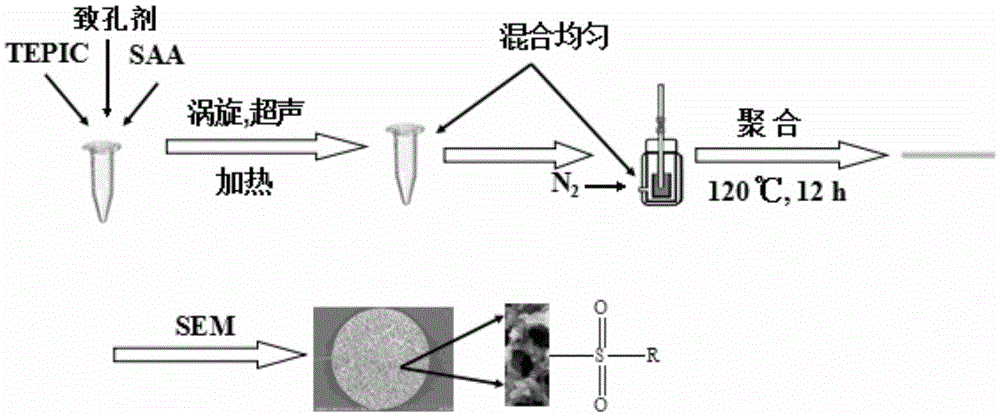

[0031] In the preparation method of the present invention, the specific amount of each raw material can be selected in a wide range, but in order to improve the rate and yield of the ring-opening copolymerization reaction, preferably, relative to 1 weight part of TEPIC, the amount of SAA is 0.4 -0.8 parts by weight, the amount of porogen is 2.5-3.2 parts by weight.

[0032] In the preparation method of the present invention, the specific reaction conditions of the ring-opening copolymerization reaction can be selected in a wide range, but in order to improve the rate and the productivity of the ring-opening copolymerization reaction, preferably, the ring-opening copolymerization reaction at least meets the following conditions: Reaction The temperature is 80-150°C, and the reaction time is 2-24h.

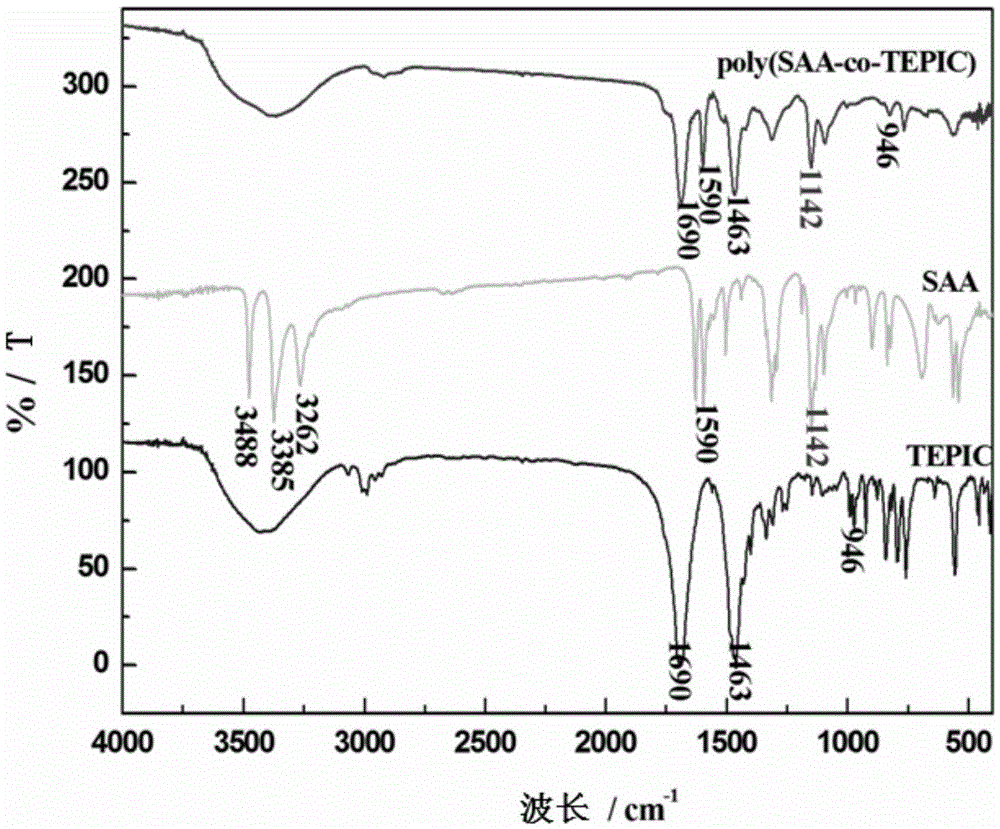

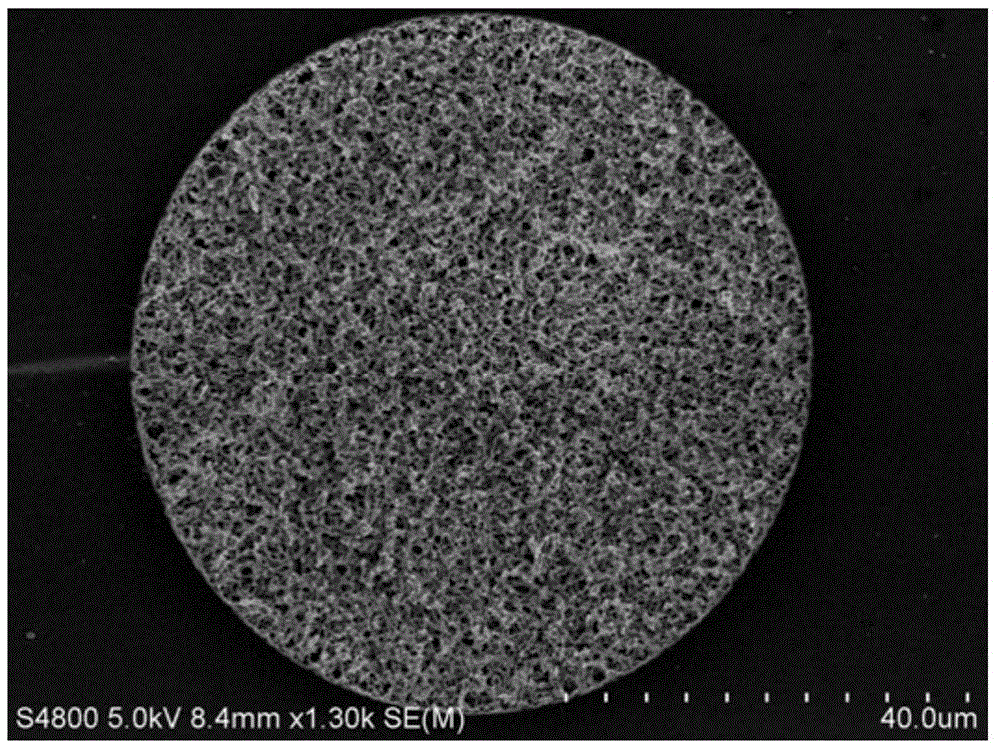

[0033] In the present invention, in order to remove unreacted small molecular substances attached to the copolymer poly(TEPIC-co-SAA), thereby improving the purity of the copolymer ...

Embodiment 1

[0046] 1) Dissolve 0.950g of TEPIC in 2.600g of PEG-300, then add 0.550g of SAA into a 10mL centrifuge tube, vortex, ultrasonically degas, and mix evenly to obtain a uniform and clear solution. Block material M1 was obtained by constant temperature copolymerization ring-opening reaction in an oven at 120°C for 12 hours;

[0047] 2) Cut 3.000g of the block material M1 into small pieces, put it into a Soxhlet extractor, add 50mL of methanol, extract at 100°C for 24 hours, wash out the residual porogen and unreacted substances, and obtain the block material M2 .

[0048] 3) Put the bulk material M2 in a vacuum drying oven and dry it at 100°C for 12 hours to obtain the monolithic material A1 of thiophilic chromatography, that is, the copolymer poly(TEPIC-co-SAA).

Embodiment 2

[0050] 1) Rinse the capillary with NaOH (0.1M), water, HCl (0.1M), water and methanol for 30min in sequence; then blow the inner wall of the washed capillary with nitrogen flow for 10h to dry; then at 50°C, dry the The capillary was placed in a mixed solution of ATMS and THF (ATMS / THF v / v 1:1) for contact reaction for 12 hours. After the reaction, the capillary was rinsed with methanol and dried with nitrogen to obtain a capillary with amino groups on the inner wall.

[0051] 2) Completely dissolve 0.095g of TEPIC in 0.260g of PEG-300, then add 0.055g of SAA into a 1.5mL centrifuge tube, vortex and sonicate to obtain a uniform and clear solution. Then, the solution was quickly injected into the capillary of the above-mentioned derivatized amino group, both ends of the capillary were sealed with silicone rubber, and the ring-opening reaction was carried out in a constant temperature oven at 120° C. for 12 hours.

[0052] 3) Take out the above-mentioned capillary tube, connect i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com