Catering waste water oil-removing treatment method

A technology for catering wastewater and oil treatment, applied in multi-stage water treatment, water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of high operating cost and low equipment cost, reduce operating cost and improve treatment The effect of low capacity, operation and maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

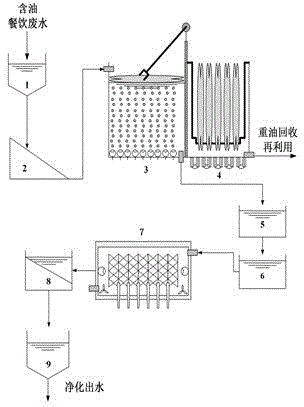

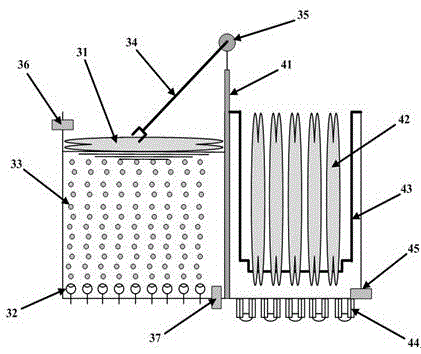

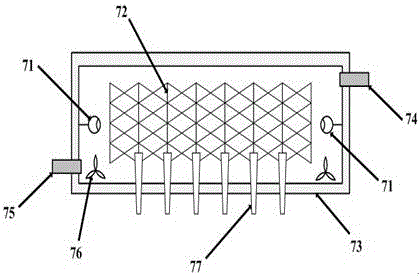

[0024] Such as figure 1 In the degreasing treatment method for catering wastewater shown, the oily catering wastewater enters the buffer pool 1 through the wastewater pipeline, where it is collected and initially stabilized. The outlet of the buffer pool 1 is connected to the coarse grid 2 through the wastewater pipeline, where the catering wastewater is removed Large-diameter solid matter in wastewater, the outlet of the coarse grid 2 is connected to the microbubble air flotation oil adsorption device 3 through the wastewater pipeline, and the π-allyl nickel compound-containing modified diatomite in the microbubble air flotation oil adsorption device 3 After the adsorption film 42 completely absorbs the oil, it will be grasped by the stainless steel mechanical arm 34 and sent to the oil catalytic heavy reforming desorption reactor 4. The heavy oil generated in the oil catalytic heavy reforming desorption reactor 4 is discharged from the heavy oil discharge port 45 and is Recy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com