Isomerization catalyst composition and isomerization catalyst as well as application thereof and preparation method therefor

A composition and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of unavailable catalysts, low conversion rate and selectivity, and reduced selectivity, and achieve low cost, The method is simple and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] In the preparation method of the present invention, preferably, the molding is such that the molded object is at least one of spherical, clover-shaped, four-leaf clover-shaped and butterfly-shaped.

[0059] In the present invention, the method of forming, drying and roasting is preferably as follows: placing the isomerization catalyst composition in an extruder for rolling and forming, and then placing the formed material at room temperature for curing such as 4- 10h, then dried overnight at 50-200°C, and calcined at 220-700°C, the time of drying and calcining is not particularly limited. In the examples of the present invention, the calcination time is exemplarily listed as 5 hours. Those skilled in the art should not understand this as a limitation on the technical solution of the present invention.

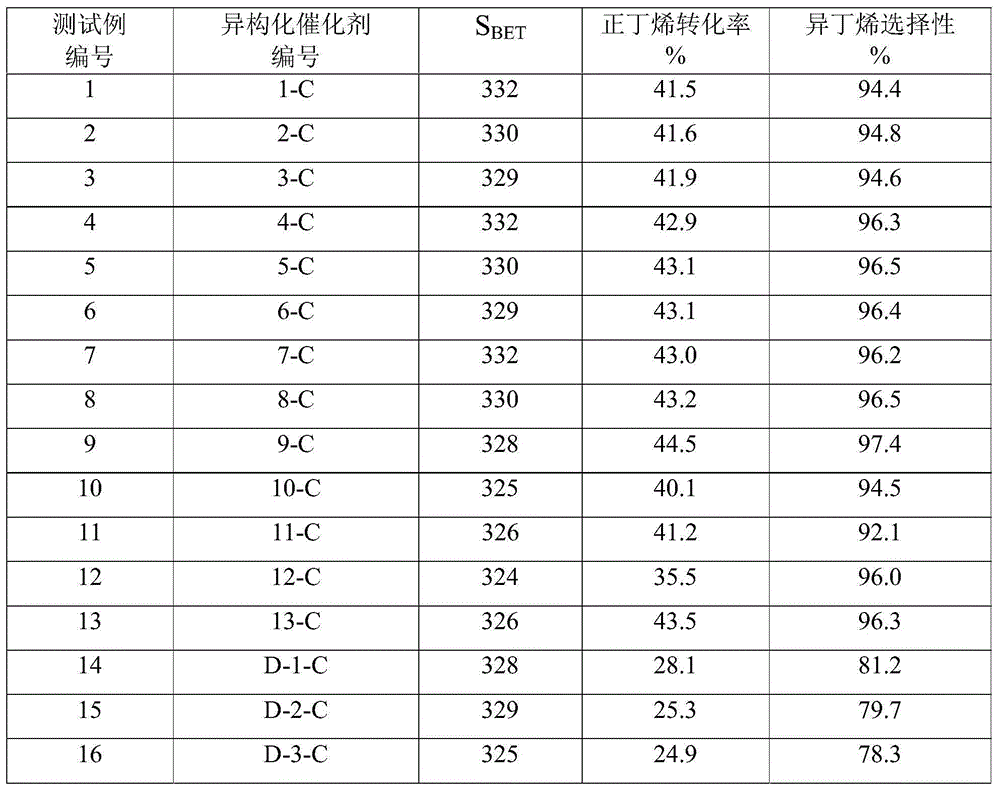

[0060] Using the isomerization catalyst of the present invention or the isomerization catalyst obtained by the above-mentioned method of the present invention for isome...

Embodiment 1

[0065] This example is used to provide the isomerization catalyst composition of the present invention and to illustrate the preparation method of the isomerization catalyst of the present invention.

[0066] Step 1: obtain modified ferrierite.

[0067] Modification treatment: Take 90g of sodium ferrierite ZSM-23 (purchased from Shanghai Shentan Environmental Protection New Material Co., Ltd., the same below), and add it to 1000mL of a solution containing 32g of ammonium nitrate and 35.4g of ammonium fluorosilicate. Contact treatment at ℃ for 8h, then cooling, filtering, drying at 100℃ for 10h, and calcining at 500℃ for 4h to obtain modified ferrierite 1-A.

[0068] The second step: obtaining the isomerization catalyst composition.

[0069] A mixed solution of 100 g of modified Ferrierite 1-A, 50 g of alumina, 5 g of turnip powder, 8 g of nitric acid and 100 g of water was added into a kneader and stirred until the materials were evenly mixed. The isomerization catalyst comp...

Embodiment 2

[0073] This example is used to provide the isomerization catalyst composition of the present invention and to illustrate the preparation method of the isomerization catalyst of the present invention.

[0074] Step 1: obtain modified ferrierite.

[0075] Modification treatment: Take 90g of sodium ferrierite ZSM-35 (purchased from Dalian Ketelli Chemical Co., Ltd., the same below), add it to 1000mL solution containing 55.4g ammonium nitrate and 72g ammonium fluorosilicate, at 95°C After contacting for 7 hours, cooling, filtering, drying at 120°C for 8 hours, and calcining at 400°C for 6 hours, the modified ferrierite 2-A was obtained.

[0076] The second step: obtaining the isomerization catalyst composition.

[0077] A mixed solution of 100 g of modified ferrierite 2-A, 20 g of silicon oxide, 10 g of methylcellulose, 4 g of nitric acid and 100 g of water was added into a kneader and stirred until the materials were mixed evenly. The isomerization catalyst composition 2-B was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com