A system for combined electrolysis-ultraviolet treatment of aquaculture circulating water

A technology for combined treatment and circulating water, applied in the field of aquaculture circulating water treatment systems, can solve the problems of ultraviolet sterilization being easily affected by water turbidity, decreased radiation intensity, and toxic effects of fish and aquatic organisms, achieving complete sterilization and reducing Residual chlorine concentration, effect of high-efficiency water treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

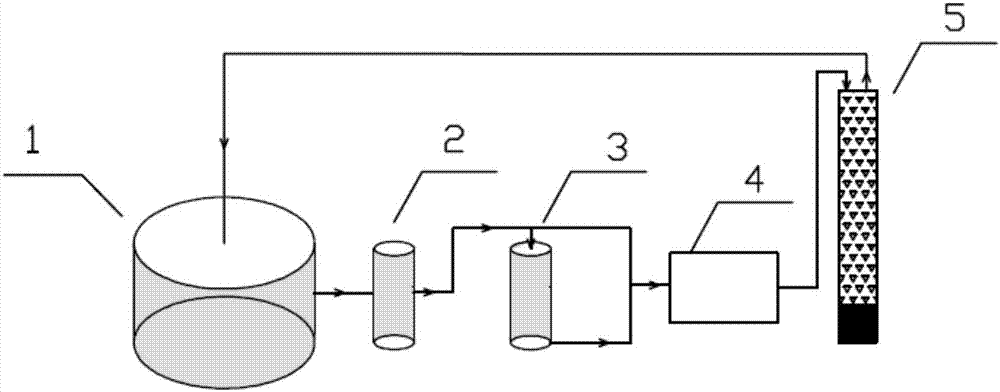

[0017] refer to figure 1 , the system of electrolysis-ultraviolet combined treatment of breeding circulating water of the present invention comprises culture pond 1, vortex separator 2, electrolyzer 3, buffer tank 4, active carbon processor 5; After the solid-liquid separation, part of the liquid directly enters the buffer tank 4, and the other part enters the electrolytic tank 3 for combined electrolysis and ultraviolet treatment. The effluent filtered by the activated carbon processor 5 is returned to the culture pond 1 to form a circulation.

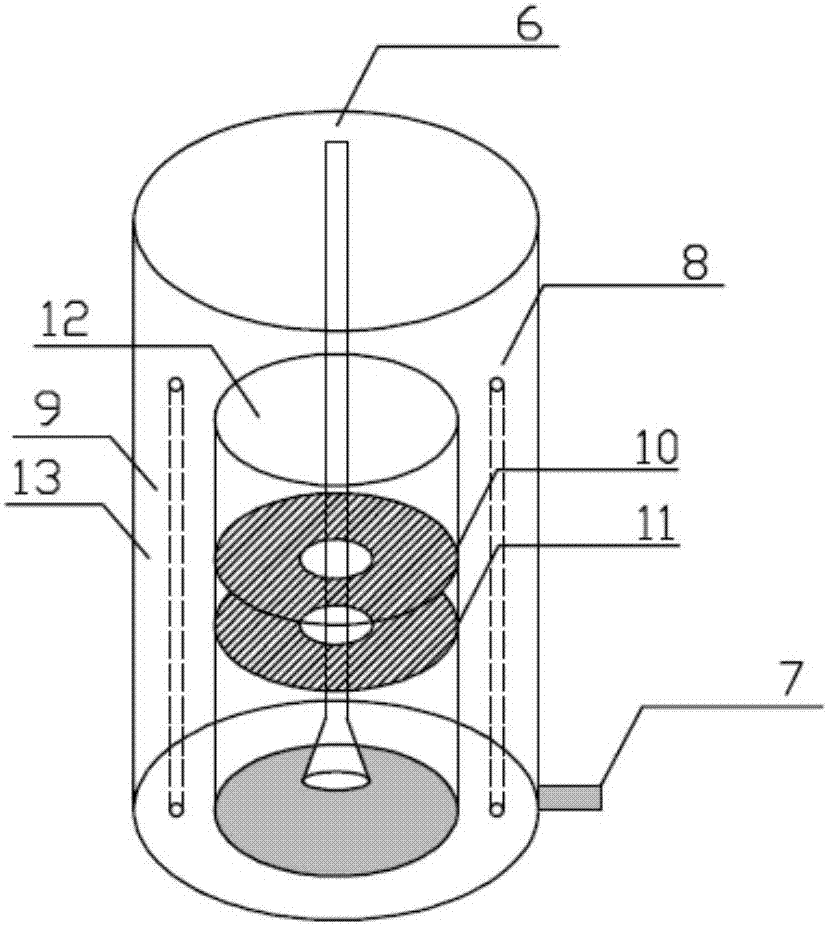

[0018] Such as figure 2 As shown, the electrolytic cell 3 includes an outer cylinder 13 and an inner cylinder 12 arranged in the outer cylinder and having a height lower than the outer cylinder. The inner cylinder 12 is provided with a water inlet pipe 6 extending into the bottom of the inner cylinder. 6 is covered with two electrode sheets 10, 11, two ultraviolet lamp tubes 8, 9 are arranged between the inner cylinder 12 and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com