Preparation method of highly-densified titanium carbide ceramic

A densification and titanium carbide technology, which is applied in the field of preparation of highly densified titanium carbide ceramics, can solve problems such as poor thermophysical properties, low production efficiency, and affecting the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention belongs to a method for preparing ceramic materials, in particular to a method for densification of titanium carbide ceramics under normal pressure sintering. Taking sub-micron titanium carbide powder (sub-micron TiC powder with an average particle size of less than 0.5μm) as the main raw material, introducing reducing carbide sintering aids, using WC, B 4 C, Cr 3 C 2 One or more of VC, C, etc. are sintering aids. After mixing, forming and debonding according to the conventional ceramic technology, sintering under the protection of argon atmosphere can realize the atmospheric sintering and densification of titanium carbide ceramics. The density of the material after sintering can reach above 98% TD (theoretical density).

[0023] The added amount of the sintering aid is 0-10 wt% of the mass of the titanium carbide powder.

[0024] The titanium carbide powder used is a commercial powder, and the particle size is sub-micron (or can reach sub-micron after ball mil...

Embodiment 1

[0032] 1. Using commercial TiC powder with an average particle size of 0.37μm as the main raw material, adding sintering aid C to 3wt%, after ball milling the mixture, pressing test strips (20MPa / 30s), cold isostatic pressing (200MPa / 120s) , After debonding (heating rate 5°C / min, debonding temperature 1200°C, holding time 3 hours), atmospheric sintering is carried out. The size of the titanium carbide ceramic material blank is: 45.5×8×6mm;

[0033] 2. Under argon atmosphere, the pressure in the furnace is maintained at a standard atmospheric pressure for normal pressure sintering, the sintering temperature is 2250℃, and the sintering time is 2 hours;

[0034] The density of TiC ceramic sintered body can reach 98.8%;

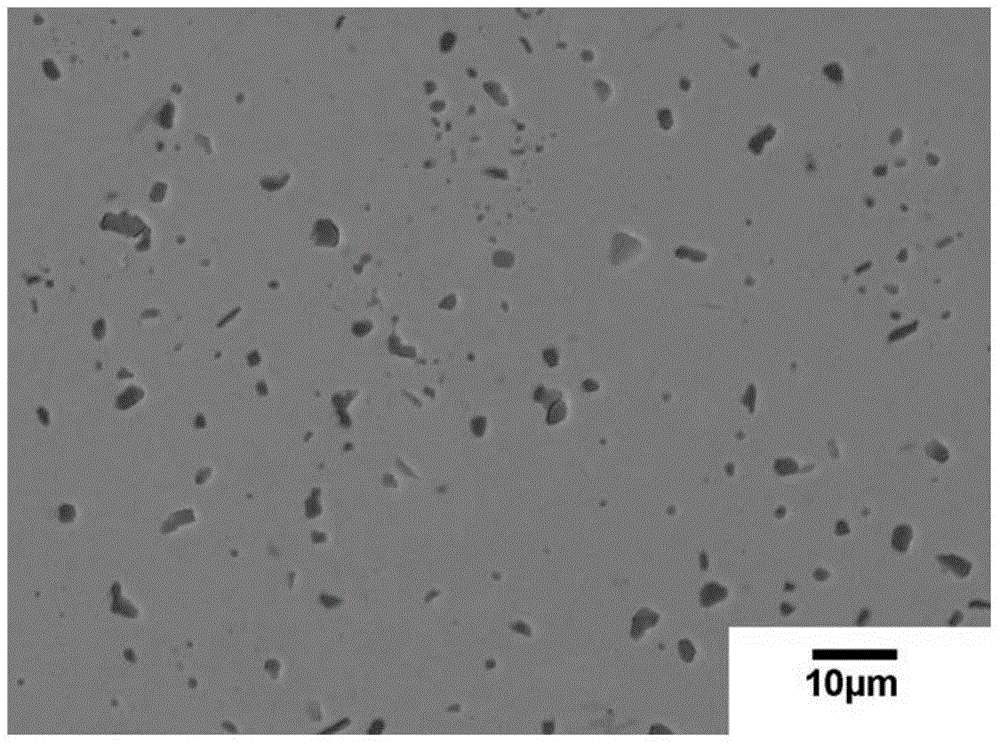

[0035] Such as figure 1 As shown, the sintering aid C in the TiC ceramic sintered body is uniformly distributed in the TiC ceramic matrix.

Embodiment 2

[0037] 1. Using commercial TiC powder with an average particle size of 0.37μm as the main raw material, adding sintering aid B4C at 8wt%, after ball milling the mixture, pressing test strips (20MPa / 30s), cold isostatic pressing (200MPa / 120s), After debonding (heating rate 0.5°C / min, debonding temperature 900°C, holding time 0.5 hours), atmospheric sintering is carried out. The size of the titanium carbide ceramic material blank is: 45.5×8×6mm;

[0038] 2. Under argon atmosphere, the pressure in the furnace is maintained at about a standard atmospheric pressure for normal pressure sintering, the sintering temperature is 2200℃, and the sintering time is 2 hours. The density of the TiC ceramic sintered body can reach 100%;

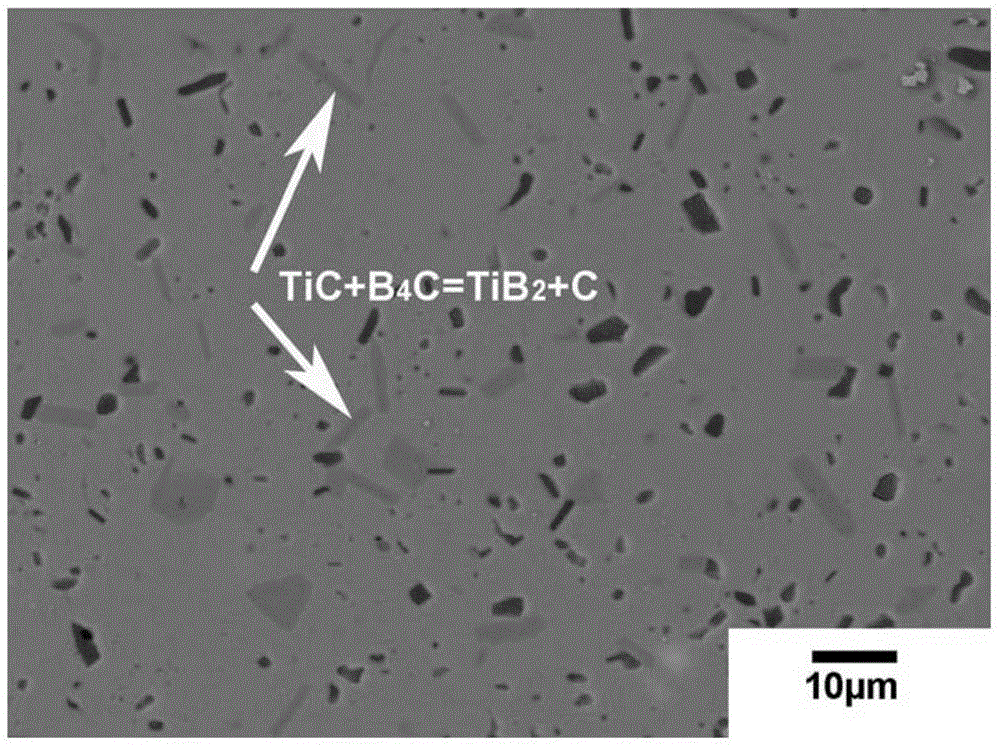

[0039] Such as figure 2 As shown, TiB formed by the reaction of sintering aid B4C with TiC in TiC ceramic sintered body 2 Evenly distributed in the TiC ceramic matrix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com