Halogen-free flame-retardant noise suppression sheet and preparation method thereof

A noise suppression sheet, flame retardant technology, applied in the field of composite material manufacturing, can solve the problems of destroying the magnetic powder arrangement, poor absorbing performance, affecting the absorbing performance, etc., to improve surface wettability, good absorbing performance, good The effect of interface combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

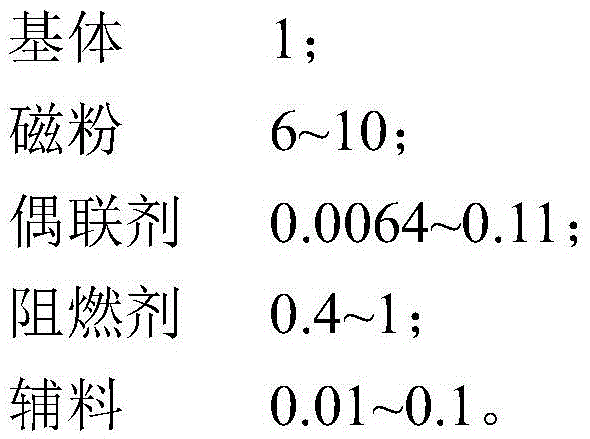

[0036] A preparation method of a halogen-free flame-retardant noise suppression sheet, comprising the following steps:

[0037] (1) Select a polymer binder as the matrix, and select a high-loss flake soft magnetic alloy powder as the magnetic powder, wherein the filling amount of the magnetic powder is 6 times the mass of the matrix;

[0038] (2), prepare the modified solution of coupling agent and solvent: join coupling agent in the solvent, the quality of solvent is 10 times of coupling agent;

[0039] (3), flame retardant surface modification: get the modified solution and flame retardant in step (2), the quality of flame retardant is 100 times of coupling agent quality in the solution, mix in proportion, fully stir, bake dry reserve;

[0040] (4), magnetic powder surface modification: get the modified solution and the magnetic powder in the step (2), the quality of the magnetic powder is 100 times of the coupling agent quality in the solution, mix in proportion, fully sti...

Embodiment 2

[0054] A preparation method of a halogen-free flame-retardant noise suppression sheet, comprising the following steps:

[0055] (1) Select a polymer binder as the matrix, and select high-loss flaky soft magnetic alloy powder as the magnetic powder, wherein the filling amount of the magnetic powder is 10 times the mass of the matrix;

[0056] (2), prepare the modified solution of coupling agent and solvent: the coupling agent is added in the solvent, and the quality of the solvent is 5000 times of the coupling agent;

[0057] (3), flame retardant surface modification: get the modified solution and flame retardant in step (2), the quality of flame retardant is 100 times of coupling agent quality in the solution, mix in proportion, fully stir, bake dry standby;

[0058] (4), surface modification of magnetic powder: get the modified solution and magnetic powder in step (2), the quality of magnetic powder is 1000 times of the coupling agent quality in the solution, mix in proporti...

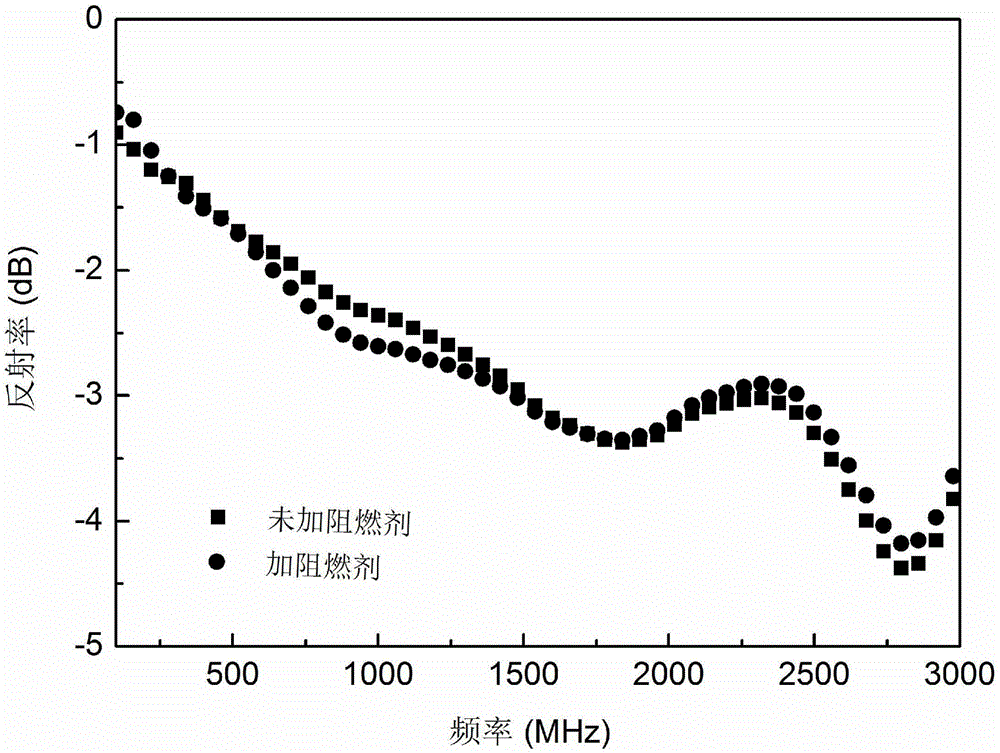

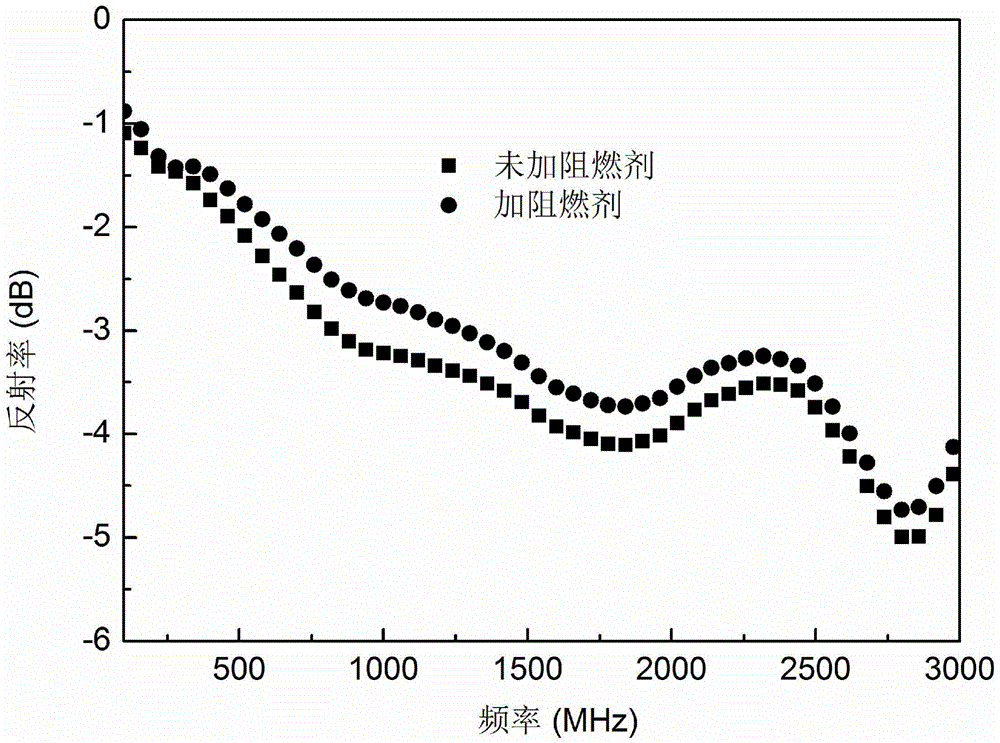

Embodiment 3 and comparative Embodiment 1

[0072] The difference between Example 3 and Example 1 is that: Nitrile rubber, flake Fe-Si-Al magnetic powder and red phosphorus are used as the matrix (binder), flat magnetic powder and flame retardant respectively. Prepare a solution of silane coupling agent (KH-550) and acetone at a ratio of 1:400, add red phosphorus flame retardant to the solution, the mass ratio of red phosphorus to silane coupling agent is 100:0.6, and use an electric mixer After stirring for 1 hour, the mixture was dried in an oven at 40° C. for 2 hours, and collected after all the solvent evaporated for future use. Mix the silane coupling agent (KH-550) and acetone at a ratio of 1:300, add Fe-Si-Al flake magnetic powder into the solution, the mass ratio of the magnetic powder to the silane coupling agent is 100:0.25, and use an electric mixer After stirring for 1 hour, the mixture was dried in an oven at 40° C. for 1.5 hours, and collected after all the solvent evaporated for future use. Put the modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com