Medium for promoting toxin-producing capability of clostridium tetani

A Clostridium and tetanus technology, applied in the direction of bacteria, microorganism-based methods, microorganisms, etc., can solve the problems of low fermentation toxin production capacity, difficult purification, low potency, etc., and achieve the effect of improving toxin production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] (3) Preparation of need testing solution: get need testing 15ml, add step (3) (1) described borate buffer 15ml, carry out 2 times dilution to obtain 2 times dilution.

[0048] Assay method: Accurately measure 0.3ml, 0.4mL, 0.5ml, 0.6ml, 0.7ml of the standard solution described in step (3) (2), add flocculent reaction tubes respectively, and each flocculent reaction tube adds step (three) ) (3) 1ml of the test solution, sow evenly, place in a water bath at 45-50°C, observe continuously, and record the order and time of flocculent appearance. Take another 5 flocculent reaction tubes, repeat the above test, put the first flocculent tube in the middle, and add different amounts of the standard solution described in step (3) (2) to the front and rear tubes, with an interval of 0.05ml between each tube , that is, each tube has a difference of 0.05ml, and then 1ml of the test solution described in step (3) (3) is added to each tube to observe the occurrence of floc. According...

Embodiment 2— Embodiment 7

[0053] Embodiment 2—Example 7 Except that the content of the materials listed in Table 4 is different, all the other components and their content and preparation, No. II factor formula and preparation, No. I factor formula and preparation, and all other operations in the medium are all the same as Embodiment 1 is the same and will not be repeated here. The results are shown in Table 5.

[0054] In table 4 embodiment 2-embodiment 7 and embodiment 1

[0055] List of differences in component content

[0056]

[0057]

[0058] Table 5 embodiment 1-embodiment 7 test product floc unit

[0059]

[0060] Above 7 embodiment results show: the medium formula of embodiment 7 is the formula most suitable for Clostridium tetani fermentation, so embodiment 7 is repeated verification, following embodiment 8, embodiment 9, embodiment 10 are Repeat verification.

[0061] The culture medium formula of embodiment 8-embodiment 10 is the same as that of embodiment 7, which is a verific...

Embodiment 1

[0063] Embodiment 11 and embodiment 12 are based on the formula of embodiment 7, and the content of each component has the ± variation described in the technical solution of the present invention, and all the other operations are the same as embodiment 1, and are not repeated. See Table 6, Table 7 and Table 8 for the formulas of No. 1 factor, No. 2 factor and culture medium in Example 11 and Example 12. The experimental results are shown in Table 9.

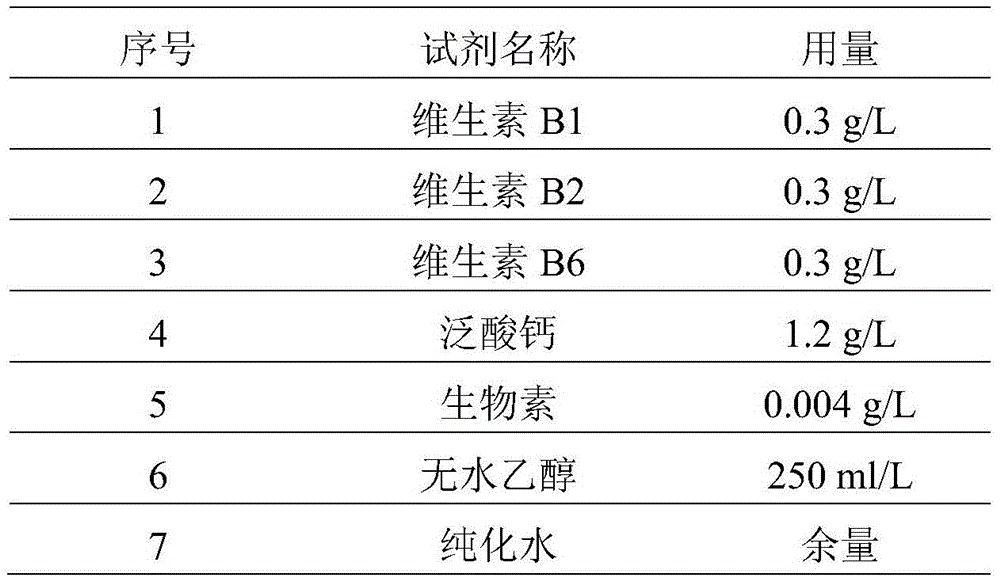

[0064] No. I factor formula in table 6 embodiment 7, embodiment 11, embodiment 12

[0065]

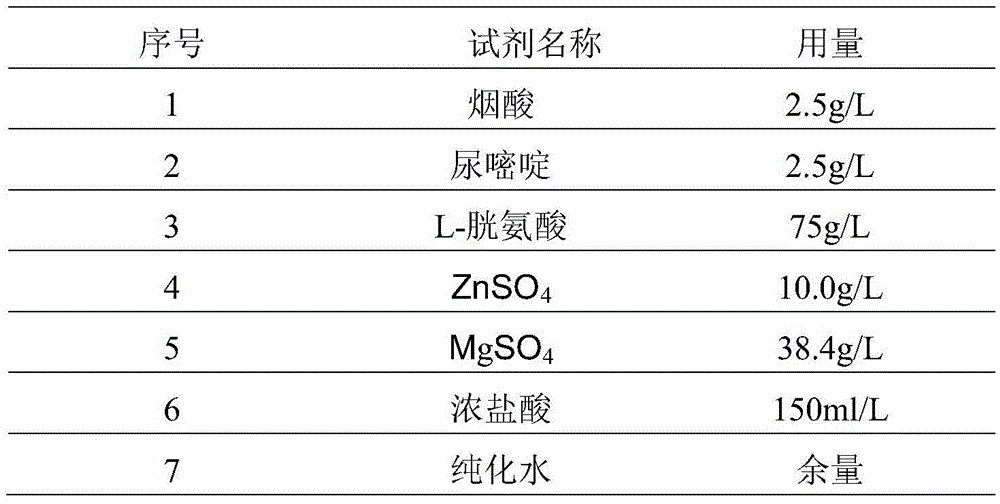

[0066] No. II factor formula in table 7 embodiment 7, embodiment 11, embodiment 12

[0067]

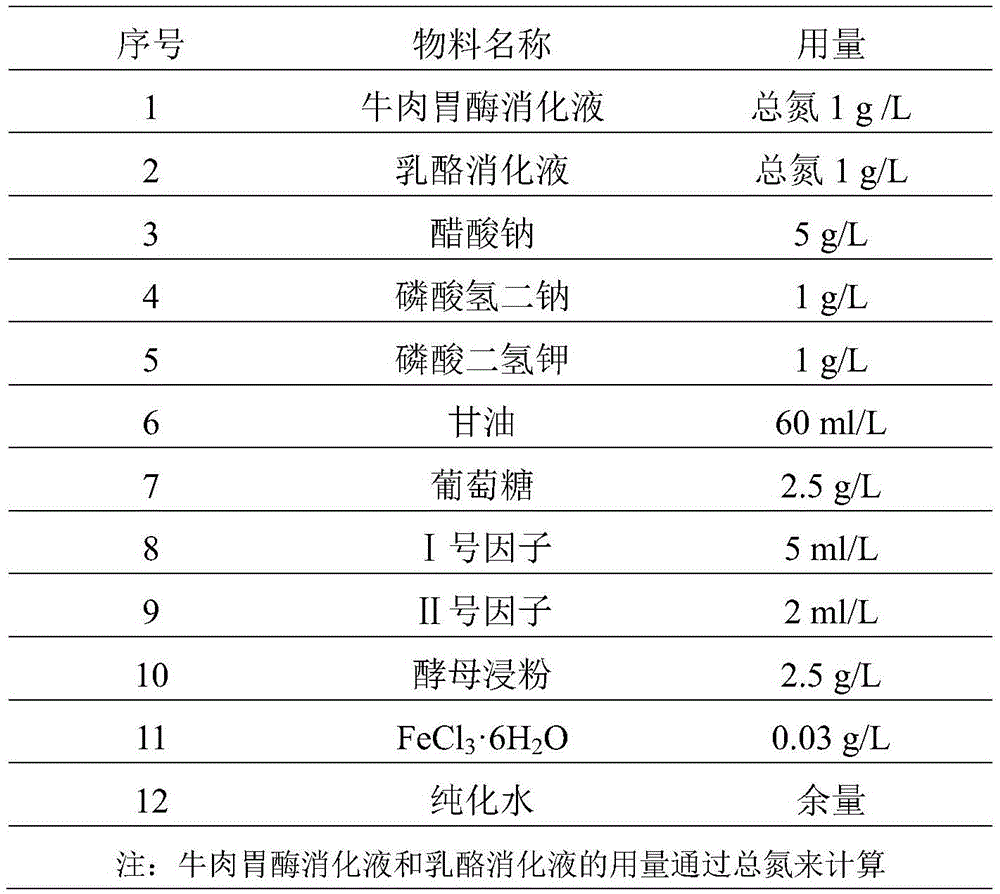

[0068] Medium formula in table 8 embodiment 7, embodiment 11, embodiment 12

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com