Hardening and tempering method of novel anti-corrosion glass die steel large-section forging material

A technology of corrosion-resistant glass and mold steel, which is applied in the quenching and tempering of pre-hardened corrosion-resistant glass mold steel large-section forgings, and in the field of glass mold steel for the production of high-grade glass products, which can solve problems such as uneven structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The size is Φ100mm finished forging material;

[0038] 1. Smelting: use electric furnace + LF + VD + electroslag remelting steel, the ingot type is Φ360 electroslag ingot, furnace number: 15229080076;

[0039] 2. Forging: 2000t fast forging + 1000t precision forging are used to form a material, the size of the finished material is Φ100mm, and the finished material is annealed after forging;

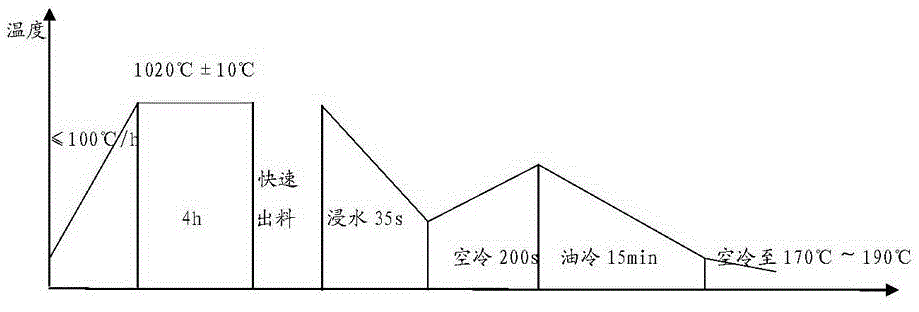

[0040] 3. Tempering: such as figure 2 As shown, the steel is heated in a trolley-type electric furnace, the heating rate is not greater than 100°C / h, and heated to 1020°C for austenitization and heat preservation for 4 hours; - After quenching during oil control (immersion in water for 35s→air cooling for 200s→oil immersion for 15min), the steel is air-cooled to between 170°C and 190°C and entered into a trolley-type electric heating furnace for tempering. The tempering temperature is 640°C and the time is 15h;

[0041] 4. Test results

[0042] ①Hardness (HRC): 32.7, 33.8, 33.1...

Embodiment 2

[0046] The size is Φ170mm finished forging material;

[0047] 1. Smelting: use electric furnace + LF + VD + electroslag remelting steel, the ingot type is Φ480 electroslag ingot, furnace number: 15229080089;

[0048] 2. Forging: 3150t fast forging + 1800t precision forging are combined to form a material, the size of the finished material is Φ170mm, and the finished material is annealed after forging;

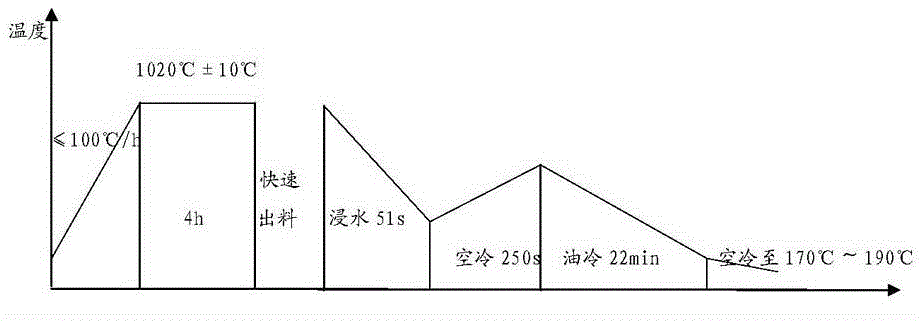

[0049] 3. Tempering: such as image 3 As shown, the steel is heated in a trolley-type electric furnace, the heating rate is not greater than 100°C / h, and heated to 1020°C for austenitization and heat preservation for 4 hours; - After quenching during oil control (immersion in water for 51s→air cooling for 250s→oil immersion for 22min), the steel is air-cooled to between 170°C and 190°C and entered into a trolley-type electric heating furnace for tempering. The tempering temperature is 640°C and the time is 20h;

[0050] 4. Test results

[0051] ①Hardness (HRC): 33.5, 34.2, 3...

Embodiment 3

[0055] The size is Φ270mm finished forging material;

[0056] 1. Smelting: use electric furnace + LF + VD + electroslag remelting steel, the ingot type is Φ610 electroslag ingot, furnace number: 15229520093;

[0057] 2. Forging: 3150t fast forging + 1800t precision forging are combined to form a material, the size of the finished material is Φ270mm, and the finished material is annealed after forging;

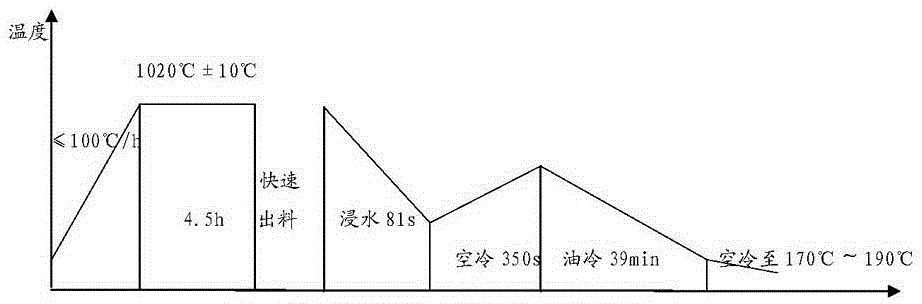

[0058] 3. Tempering: such as Figure 4As shown, the steel is heated in a trolley-type electric furnace, the heating rate is not greater than 100°C / h, heated to 1020°C for austenitization and heat preservation for 4.5 hours; Quenching during air-oil control (immersion in water for 81s→air cooling for 350s→oil immersion for 39min) After treatment, the steel is air-cooled to between 170°C and 190°C and entered into a trolley-type electric heating furnace for tempering. The tempering temperature is 640°C and the time is 25h;

[0059] 4. Test results

[0060] ①Hardness (HRC): 33....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com