Gluconic acid cyanide-free gold-electroplating solution and electroplating method thereof

A gluconic acid and cyanide-free gold plating technology, applied in the field of electroplating copper and tin, can solve the problems of restricting the promotion of cyanide-free gold plating, low coating quality, poor plating solution performance, etc., and achieves excellent plating solution performance, high brightness, Good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

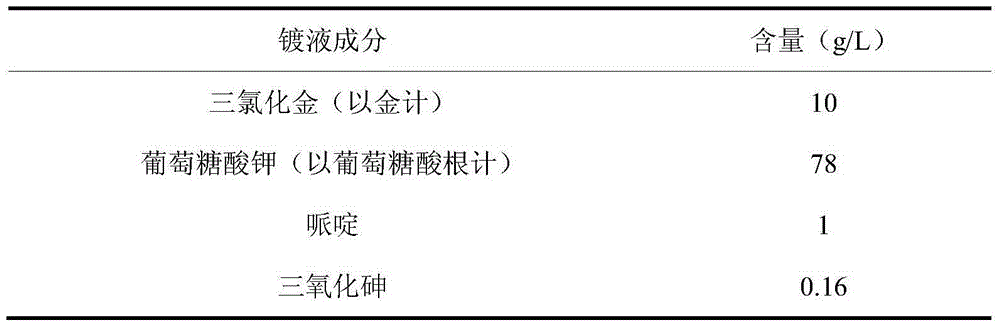

[0032] The formulation of the electroplating solution is as follows:

[0033]

[0034] Plating process conditions: the pulse width of single pulse square wave current is 0.5ms, the duty cycle is 30%, and the average current density is 0.5A / dm 2 ; The pH is 6, the temperature is 60°C, and the electroplating time is 40min.

Embodiment 2

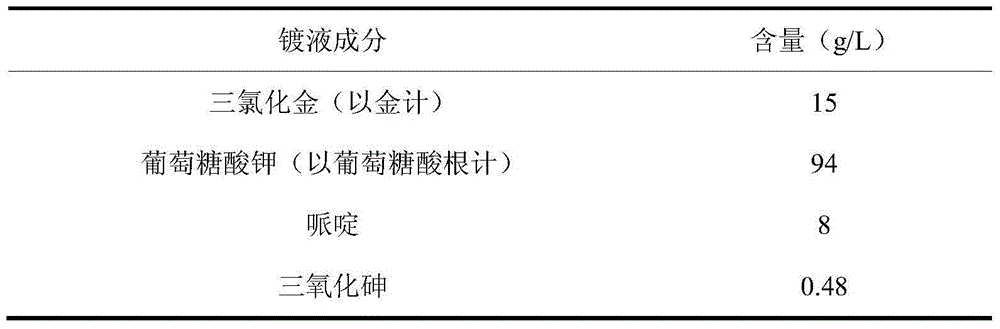

[0036] The formulation of the electroplating solution is as follows:

[0037]

[0038] Plating process conditions: the pulse width of single pulse square wave current is 0.6ms, the duty cycle is 25%, and the average current density is 0.6A / dm 2 ; The pH is 6.5, the temperature is 60°C, and the electroplating time is 35min.

Embodiment 3

[0040] The formulation of the electroplating solution is as follows:

[0041]

[0042]

[0043] Plating process conditions: the pulse width of single pulse square wave current is 0.8ms, the duty cycle is 20%, and the average current density is 1A / dm 2 ; The pH is 7, the temperature is 50° C., and the electroplating time is 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com