A rocker shearer peak load control system and control method

A peak load, shearer technology, used in fluid pressure actuation system testing, slitting machinery, earth-moving drilling, etc. Loss, operation delay and other problems, to achieve the effect of improving energy utilization, efficiently adjusting supply pressure, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

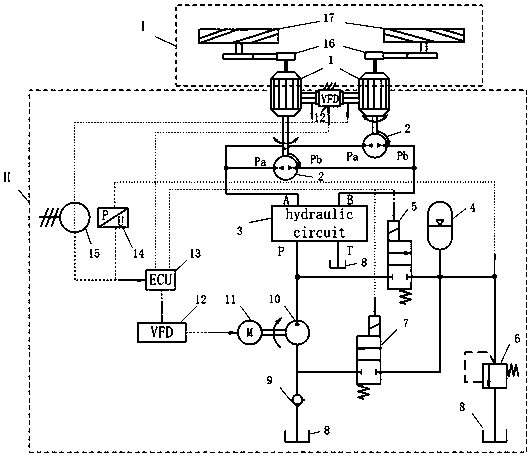

[0019] Example: such as figure 1 As shown, the hydraulic control system of the shearer to handle the peak load of the present invention is connected with the mechanical rotation system of the rocker shearer.

[0020] The mechanical rotation system of the rocker shearer includes the main motor 1, the traction drive system 16 of the rocker shearer, and the spiral drum 17 of the rocker shearer;

[0021] The main motor 1 is connected with the spiral drum 17 of the rocker shearer through the rocker shearer traction drive system 16 .

[0022] The hydraulic control system for coal shearer handling peak load includes: hydraulic pump motor 2, hydraulic circuit 3, accumulator 4, first solenoid valve 5, safety valve 6, second solenoid valve 7, oil tank 8, one-way valve 9 , auxiliary hydraulic pump 10, auxiliary motor 11, frequency converter 12, control unit 13, pressure sensor 14, transformer 15;

[0023] The hydraulic pump motor 2 is connected to the main motor 1 of the rocker shearer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com