Packaging method suitable for outer space detector beryllium window

A packaging method and outer space technology, applied in the manufacture of discharge tubes/lamps, electrical components, cold cathodes, etc., can solve the problems of poor air tightness and high outgassing rate of beryllium windows, so as to improve air tightness and improve Utilization rate, the effect of reducing outgassing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a packaging method suitable for beryllium windows of outer space detectors, which specifically includes the following steps: S1, weighing the A component and the B component of the 2216Gray epoxy resin at a mass ratio of 1:1, spare;

[0034] S2, put the epoxy resin A component and B component weighed in step S1 in a vacuum degree of Mix in a vacuum environment of <100Pa, and stir evenly until there are no bubbles on the surface of the colloid, and then fill the vacuum environment with pure nitrogen to 1 standard atmospheric pressure, for use;

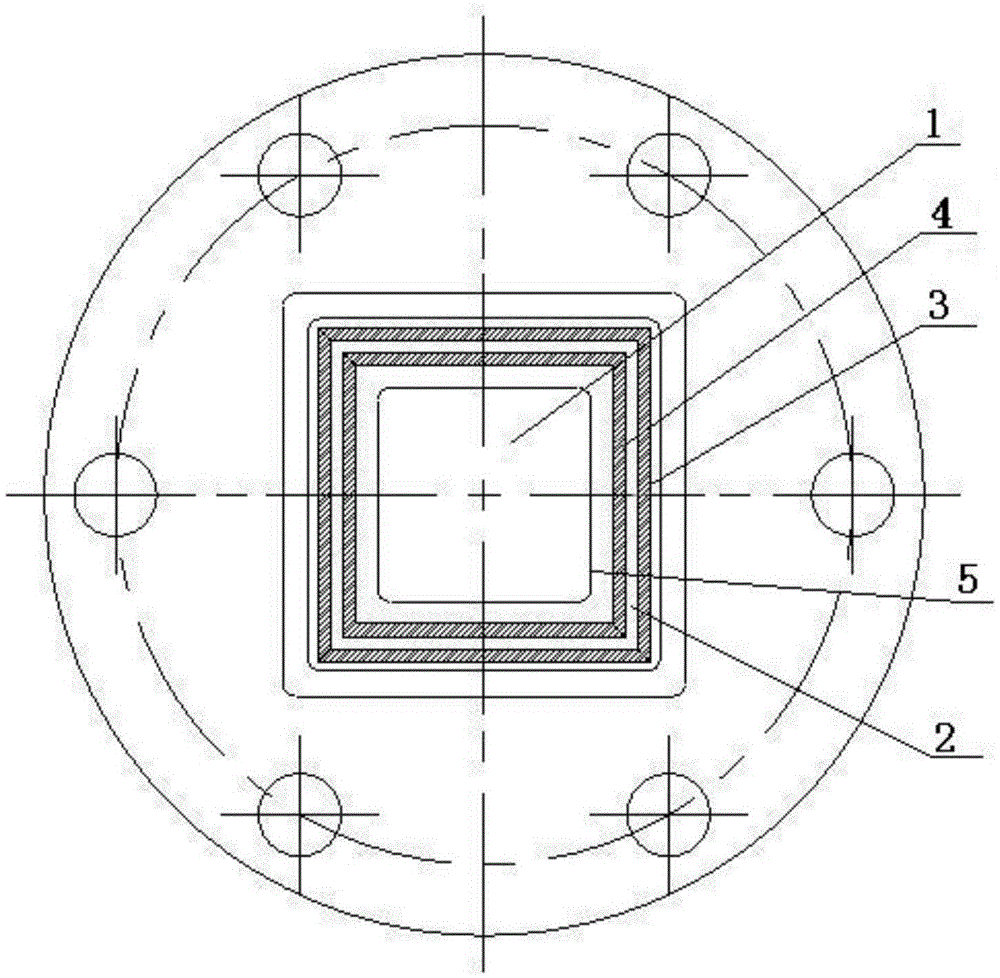

[0035] S3, uniformly coating the epoxy resin mixture obtained in step S2 on the sealing surface 2 of the beryllium window 1, and then pressing the beryllium sheet on the sealing surface;

[0036] S4, heating and curing the beryllium window 1 in step S3, controlling the heating temperature to be 90° C., and the heating time to be 1.5 hours.

Embodiment 2

[0038] This embodiment provides a packaging method suitable for beryllium windows of outer space detectors, which specifically includes the following steps: S1. Weigh the A component and B component of 2216Gray epoxy resin according to a mass ratio of 3:1, spare;

[0039] S2. Place the epoxy resin A component and B component weighed in step S1 in a vacuum environment with a vacuum of 99 Pa and mix them, and stir them until there are no bubbles on the surface of the colloid, and then fill the vacuum environment Enter pure nitrogen to 1 standard atmosphere for use;

[0040] S3, uniformly coating the epoxy resin mixture obtained in step S2 on the sealing surface 2 of the beryllium window 1, and then pressing the beryllium sheet on the sealing surface;

[0041] S4, heat curing the beryllium window 1 in step S3, the heating temperature is 100° C., and the heating time is 0.5 hours.

Embodiment 3

[0043] This embodiment provides a packaging method suitable for beryllium windows of outer space detectors, which specifically includes the following steps: S1. Weigh the A component and B component of 2216Gray epoxy resin according to a mass ratio of 2:1, spare;

[0044] S2. Place the epoxy resin A component and B component weighed in step S1 in a vacuum environment with a vacuum of 50 Pa for mixing, and stir evenly until there are no bubbles on the surface of the colloid, and then fill the vacuum environment Enter pure nitrogen to 1 standard atmosphere for use;

[0045] S3, uniformly coating the epoxy resin mixture obtained in step S2 on the sealing surface 2 of the beryllium window 1, and then pressing the beryllium sheet on the sealing surface;

[0046] S4, heat curing the beryllium window 1 in step S3, the heating temperature is 95°C, and the heating time is 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com