Preparation method of high-capacity anode material

A negative electrode material and high-capacity technology, which is applied in the field of preparation of high-capacity negative electrode materials for lithium-ion batteries, can solve the problems that the performance of composite materials is difficult to be greatly improved, it is difficult to insert Si and Sn, and the irreversible capacity is high, so as to achieve excellent cycle Performance, improvement of cycle performance, effect of reducing volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

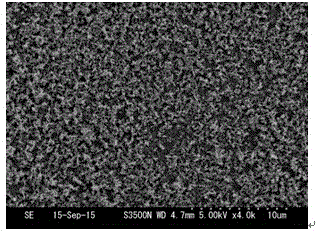

[0035] First, add 250 grams of nano-silica powder to 5 kg of petroleum asphalt, raise the temperature to 200°C, stir at high speed for 1 hour, then raise the temperature to 400°C, keep the temperature constant for 2 hours, wash, separate and dry, then put it into the atmosphere furnace, 800°C After carbonization for 1 hour, a core-shell structure composite material with a particle size distribution of 6 μm was obtained, and the nano silicon powder was completely coated in the mesophase carbon microspheres.

Embodiment 2

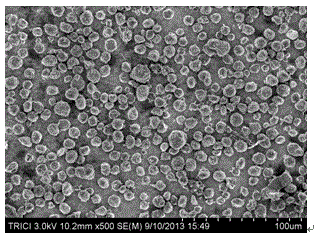

[0037] Add 25 grams of nano-silicon powder and 100 grams of mesocarbon microspheres into a 500ml ball mill tank with a ball-to-material ratio of 3:1, and ball mill for 2 hours at a speed of 400 rpm to obtain a silicon-mesophase carbon microsphere composite material. The phase carbon microspheres are broken, and most of the nano-silica powder is attached to the surface of the mesophase carbon microspheres.

Embodiment 3

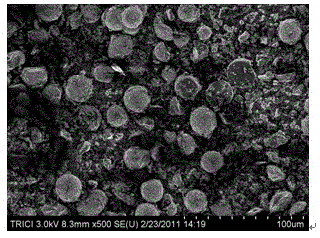

[0039] First, add 250 grams of nano-silicon and 250 grams of nano-tin monoxide powder into a mixture of 1 kg of coal tar pitch, 2 kg of petroleum pitch and 2 kg of heavy oil, raise the temperature to 250 ° C, stir at high speed for 1 hour, and then raise the temperature to 400 ° C , kept at a constant temperature for 8 hours, washed, separated and dried, then placed in an atmosphere furnace, and carbonized at 900°C for 1 hour to obtain a core-shell structure composite material with a particle size distribution of 18 μm. The nano-tin dioxide powder was completely coated in the mesophase carbon particles in the ball.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com