Ultrasonic spray coating of conducting and transparent films from combined graphene and conductive nano filaments

A conductive nanometer and ultrasonic spraying technology, applied to conductive materials dispersed in non-conductive inorganic materials, spraying devices with movable outlets, coatings, etc., can solve problems such as reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

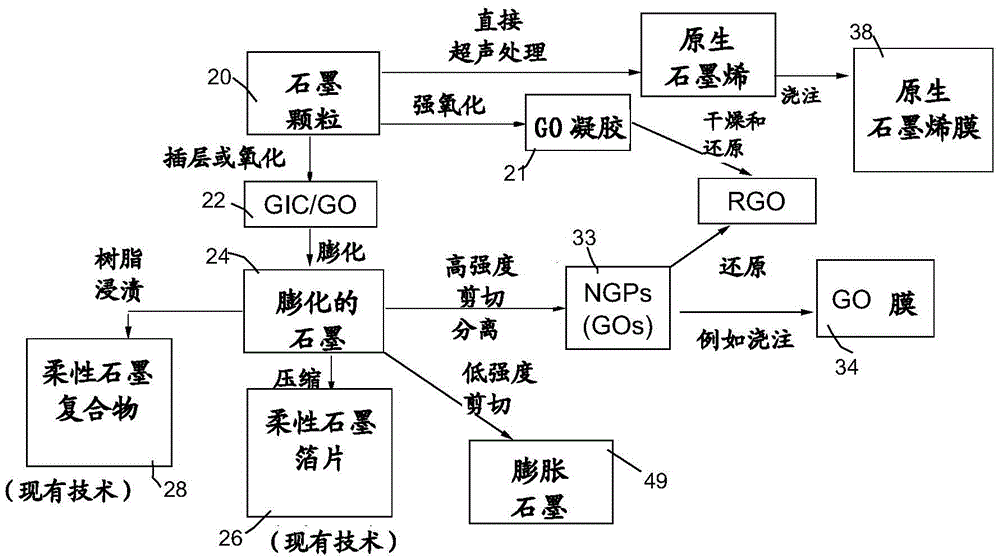

[0098] Example 1: Production of native graphene by direct sonication of natural graphite in a low surface tension medium

[0099] As an example, five grams of natural graphite ground to a size of about 20 μm or less was dispersed in 1000 mL of n-heptane to form a graphite suspension. The sonicator tip was then immersed in the suspension, which was maintained at a temperature of 0-5°C during the subsequent sonication. An ultrasonic energy level of 200 W (Branson S450 ultrasonic generator) was used for exfoliation and separation of graphene planes from dispersed graphite particles for a period of 1.5 hours. The average thickness of the produced native graphene sheets was 1.1 nm, with mainly single-layer graphene and some few-layer graphene.

Embodiment 2

[0100] Example 2: Preparation of native graphene from natural graphite in water-surfactant medium using direct sonication

[0101] As another example, five grams of graphite flakes ground to a size of about 20 μm or less were dispersed in 1000 mL of deionized water (containing 0.15% by weight of dispersant, FSO, obtained from DuPont) to obtain a suspension. An ultrasonic energy level of 175 W (Branson S450 ultrasonic generator) was used for exfoliation, separation and size reduction for a period of 1.5 hours. This process was repeated several times, each time using five grams of starting graphite powder, in order to produce sufficient quantities of native graphene for film deposition.

Embodiment 3

[0102] Embodiment 3: use supercritical fluid to prepare native graphene

[0103] A natural graphite sample (approximately 5 grams) was placed in a 100 ml high pressure vessel. The container is equipped with safety clips and rings which isolate the interior of the container from the atmosphere. The vessel is in fluid communication with high pressure carbon dioxide through plumbing and restricted by a valve. A heating jacket is placed around the vessel to achieve and maintain the critical temperature of carbon dioxide. High pressure carbon dioxide is introduced into the vessel and maintained at about 1100 psig (7.58 MPa). Subsequently, the vessel was heated to about 70°C, at which temperature supercritical conditions of carbon dioxide were achieved and maintained for about 3 hours, allowing the carbon dioxide to diffuse into the inter-graphene spaces. Immediately thereafter, the vessel was "suddenly" depressurized at a rate of about 3 ml / sec. This is achieved by opening the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com