Stabilizing treatment method for sulfide arsenic-removed dregs

A stabilization treatment, arsenic sulfide technology, applied in the direction of solid waste removal, etc., can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

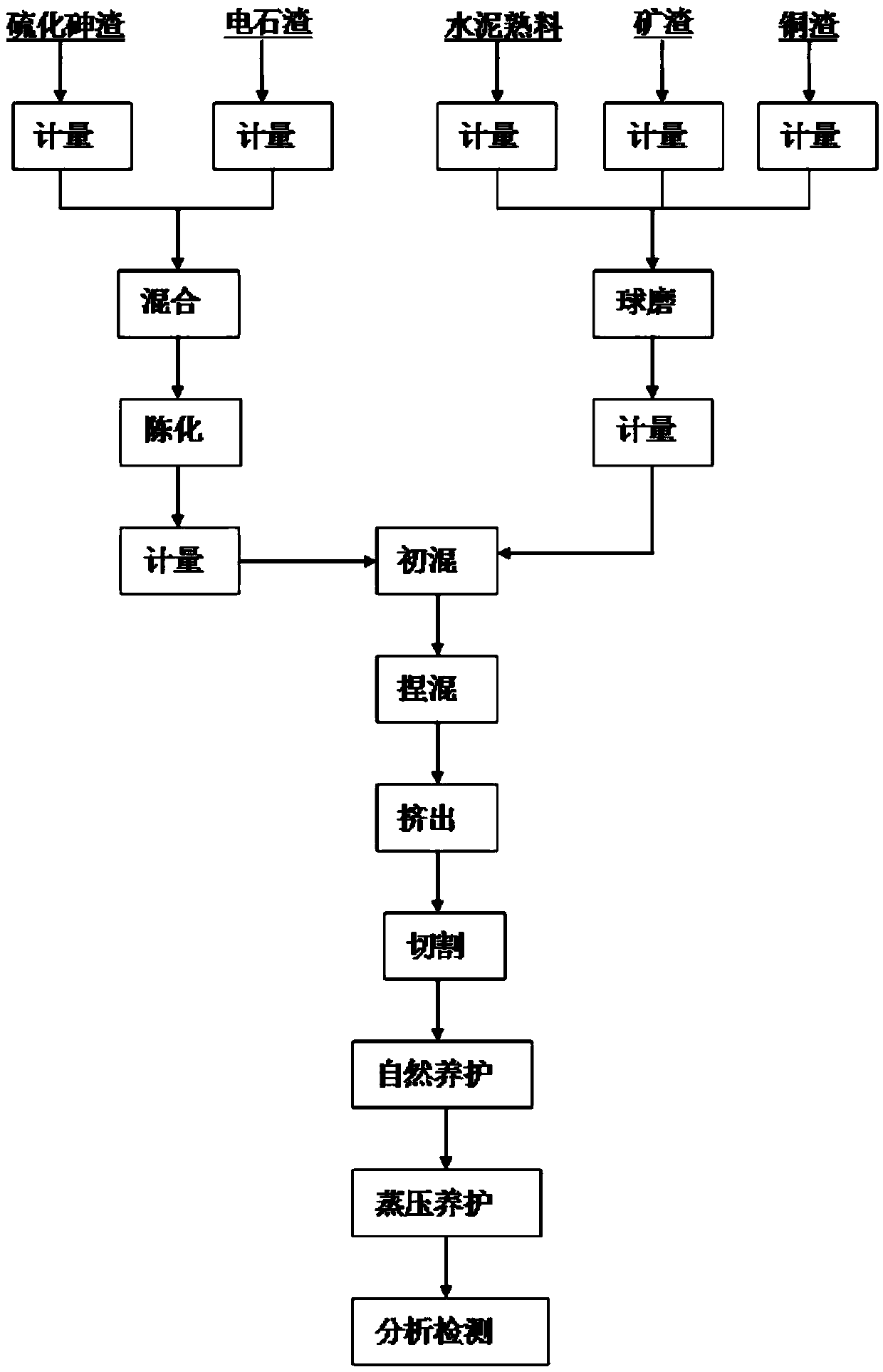

[0045] like figure 1 Shown, 1) Raw material and raw material pretreatment

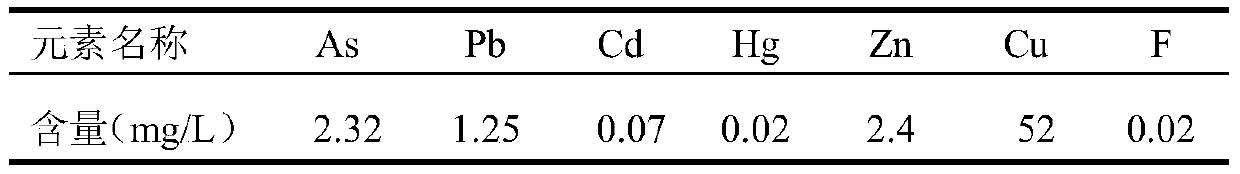

[0046] (1) Using copper smelting arsenic sulfide slag as raw material, its main element composition is shown in Table 1.

[0047] Table 1 Composition of main toxic elements in arsenic sulfide slag from copper smelting

[0048]

[0049] (2) preparation of cementitious material: get 25 parts of cement clinker, 70 parts of dry slag, 5 parts of dry copper slag, carry out ball milling with ball mill, particle size requirement is to cross 180 mesh square hole sieves and the remainder is less than 5wt%, stand-by;

[0050] (3) Pretreatment of arsenic sulfide slag: take 10 parts of dry basis of arsenic sulfide slag and 10 parts of carbide slag, mix them evenly in a horizontal mixer, and age for 24 hours for use.

[0051] 2) Process: Take 75 parts of self-made cementitious materials, 25 parts of dry base samples pretreated with arsenic sulfide slag (after analysis, its moisture content is 52.82wt%), that is...

Embodiment 2

[0057] 1) Raw materials and raw material pretreatment

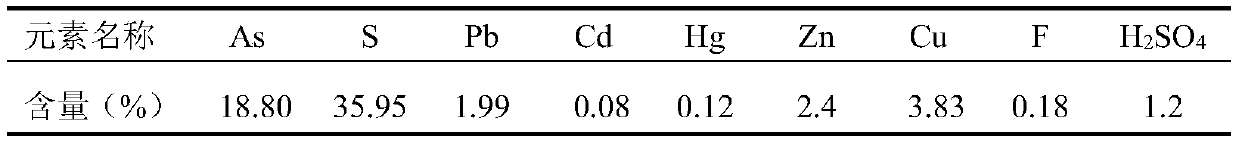

[0058] (1) Using tin smelting arsenic sulfide slag as raw material, its main element composition is shown in Table 3.

[0059] Table 3 Composition of main toxic elements in tin smelting arsenic sulfide slag

[0060]

[0061] (2) preparation of cementitious material: get 30 parts of cement clinker, 60 parts of dry slag, 10 parts of dry copper slag, carry out ball milling with ball mill, particle size requirement is to cross 180 mesh square hole sieves and the remainder is less than 5wt%, stand-by;

[0062] (3) Pretreatment of arsenic sulfide slag: take 10 parts of dry basis of arsenic sulfide slag and 12 parts of carbide slag, mix them evenly in a horizontal mixer, and age for 24 hours for use.

[0063] 2) Process: take 70 parts of self-made cementitious materials, 30 parts of dry base samples pretreated with arsenic sulfide slag (after analysis, its moisture content is 45.25wt%), that is, 54.79 parts of wet materials,...

Embodiment 3

[0070] 1) Raw materials and raw material pretreatment

[0071] (1) Using copper smelting arsenic sulfide slag as raw material, its main element composition is shown in Table 5.

[0072] Table 5 Composition of main toxic elements in copper smelting arsenic sulfide slag

[0073]

[0074] (2) Preparation of cementitious material: get 28 parts of cement clinker, 67 parts of dry slag, and 5 parts of dry copper slag, and carry out ball milling with a ball mill.

[0075] (3) Pretreatment of arsenic sulfide slag: Take 10 parts of dry basis of arsenic sulfide slag and 11 parts of carbide slag, mix them evenly in a horizontal mixer, and age for 24 hours for use.

[0076] 2) Process: Take 65 parts of self-made cementitious materials, 35 parts of dry base samples pretreated with arsenic sulfide slag (after analysis, its moisture content is 42.25wt%), that is, 60.61 parts of wet materials, and the added effective chloride content is 75wt% 0.13 part of industrial water treatment calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com