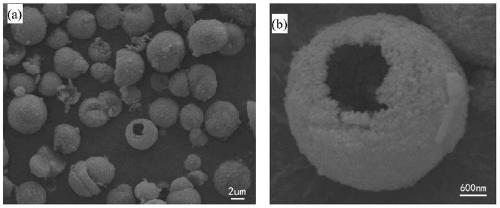

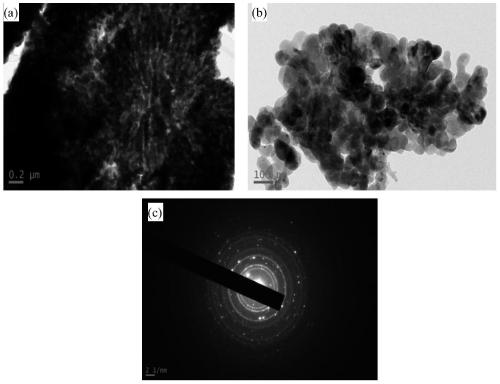

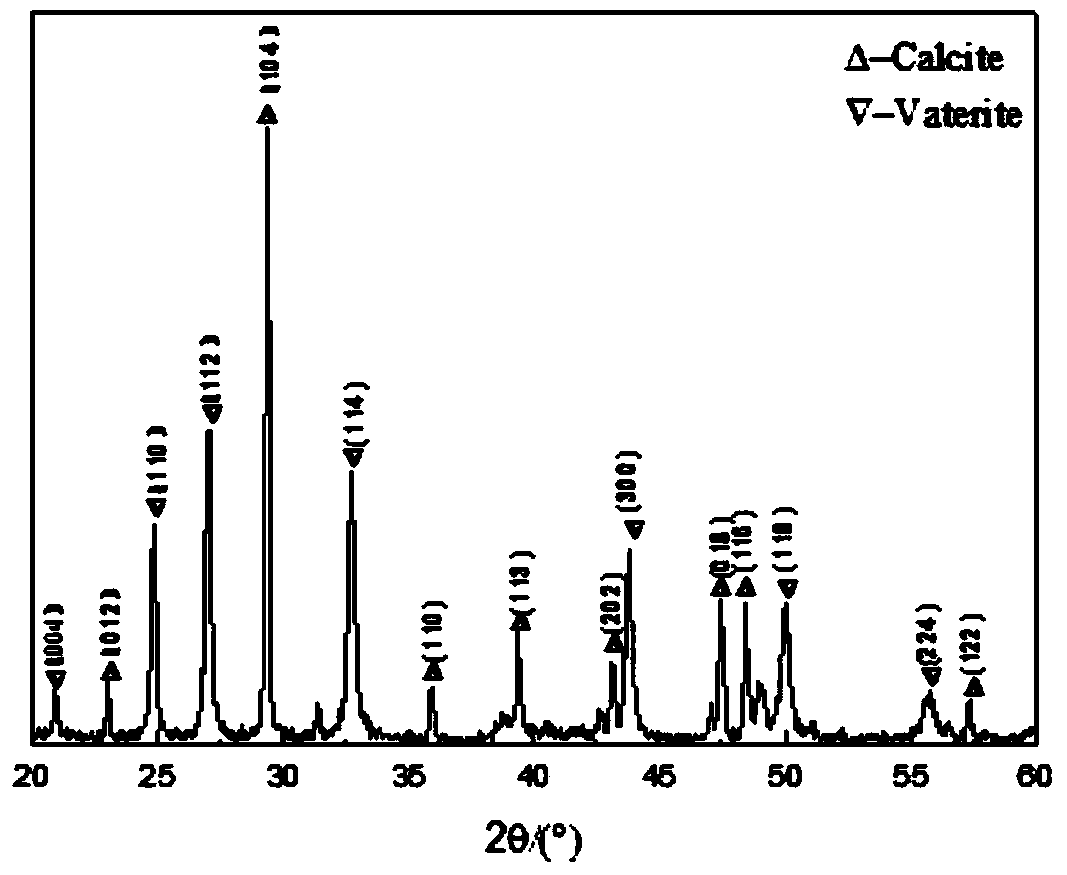

A kind of preparation method of micro-nano hierarchical pore structure calcium carbonate hollow microspheres

A calcium carbonate, graded pore technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve weak force, difficult to control calcium carbonate crystal morphology, poor compatibility and other problems, to achieve the effect of strong force, excellent structural characteristics and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Accurately weigh 1.11gCaCl 2 And dissolve it in a beaker with 100mL distilled water, stir evenly to prepare CaCl 2 solution; accurately weigh 2.12gNa 2 CO 3 And dissolve it in a beaker with 200mL distilled water, stir evenly to prepare Na 2 CO 3 solution; accurately weigh 2.72g SDSN and dissolve it in a beaker with 100mL distilled water, stir evenly to prepare SDSN solution; weigh 0.4g PVP and 100mL CaCl respectively 2 solution, 200mLNa 2 CO 3 The solution is mixed and stirred well. Under the conditions of reaction temperature of 50°C and magnetic stirring, 100 mL of CaCl 2 / PVP mixed solution dropwise into the SDSN solution, and after stirring for 30min, 200mLNa 2 CO 3 / PVP solution, dropwise added to CaCl 2 / PVP / SDSN mixed solution, control the rate of addition, so that the addition time is 1h, after the reaction, continue to stir for 4h, then filter the reaction product after standing for 12h; wash the precipitate with distilled water and absolute ethanol f...

Embodiment 2

[0035] Accurately weigh 1.11gCaCl 2 And dissolve it in a beaker with 100mL distilled water, stir evenly to prepare CaCl 2 solution; accurately weigh 2.12gNa 2 CO 3 And dissolve it in a beaker with 200mL distilled water, stir evenly to prepare Na 2 CO 3 solution; accurately weigh 2.72g SDSN and dissolve it in a beaker with 100mL distilled water, stir evenly to prepare SDSN solution; weigh 0.8g PVP and 100mL CaCl 2 solution, 200mLNa 2 CO 3 The solution is mixed and stirred well. Under the conditions of reaction temperature of 50°C and magnetic stirring, 100 mL of CaCl 2 / PVP mixed solution dropwise into the SDSN solution, and after stirring for 30min, 200mLNa 2 CO 3 / PVP solution, dropwise added to CaCl 2 / PVP / SDSN mixed solution, control the rate of addition, so that the dropping time is 0.5h; after the reaction is over, continue to stir for 2h, then filter the reaction product after standing for 24h; wash the precipitate with distilled water and absolute ethanol for 3 ...

Embodiment 3

[0037] Accurately weigh 1.11gCaCl 2 And dissolve it in a beaker with 100mL distilled water, stir evenly to prepare CaCl 2 solution; accurately weigh 2.12gNa 2 CO 3 And dissolve it in a beaker with 200mL distilled water, stir evenly to prepare Na 2 CO 3 solution; accurately weigh 3.27g SDSN and dissolve it in a beaker filled with 100mL distilled water, stir evenly to prepare SDSN solution; weigh 0.4g PVP and 100mL CaCl 2 solution, 200mLNa 2 CO 3 The solution is mixed and stirred well. Under the conditions of reaction temperature of 50°C and magnetic stirring, 100 mL of CaCl 2 / PVP mixed solution dropwise into the SDSN solution, and after stirring for 30min, 200mLNa 2 CO 3 / PVP solution, dropwise added to CaCl 2 / PVP / SDSN mixed solution, control the rate of addition, so that the addition time is 1h, after the reaction, continue to stir for 3h, and then filter the reaction product after standing for 24h; wash the precipitate with distilled water and absolute ethanol for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com